Abstract

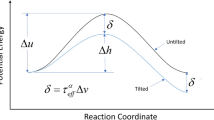

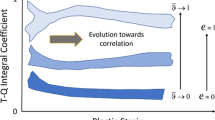

In part 1, we formally defined important physical concepts in statistical thermodynamics that undergird internal state variable (ISV) theory such as configurational subsystems (e.g., individual grains or phases), constrained local equilibrium, and thermally activated dislocation reactions in the context of crystal plasticity. The primal importance of the Gibbs free energy barrier to dislocation reactions within each subsystem was emphasized since the enthalpy barriers are affected by local constraint and resulting long-range and short-range athermal internal stresses acting within subsystems. In this work, we formally apply Gibbsian thermodynamics up to the saddle point of pending dislocation barrier reactions. The partition function based on reaction probability serves as the statistical mechanics basis for the change of Gibbs free energy that drives pending ensemble reactions; it is employed to define both the changes of the thermal entropy and configurational entropy of pending reactions; the latter enumerates reactions not only within subsystems, but also over permutations of subsystems, consistent with a multiscale hierarchy. Intrinsic entropy produced via post-reaction dynamic rearrangement and glide is of purely thermally dissipative character, being coupled to the thermal bath via dispersive phonon dynamics, and is distinguished from the entropy change of pending reactions. Building on the important concept of degree of correlation of thermally activated dislocation processes both within each subsystem and across the ensemble of subsystems introduced in part 1, we argue that nonequilibrium trajectories progressively trend toward increased correlation of enthalpy barriers across subsystems of the ensemble by virtue of internal stress redistribution among hard (unfavorable for extended dislocation reactions) and soft (more favorable) subsystems. The degree of correlation is a many-body concept involving populations of dislocations within and among various configurational subsystems. The present statistical thermodynamics framework invokes the constrained local equilibrium approach that fully respects heterogeneity of subsystems and distributions of barrier strengths, in common with ISV theory. However, literature forms of ISV theories are almost universally of reduced-order character to reduce complexity. Accordingly, reduced-order representations of ISV theory are presented for fully correlated conditions, as in standard representations of the hardening laws and flow kinetics of crystal plasticity, along with potential variations relevant to decorrelated behavior, including transients induced by unloading or changes in direction of the external applied stress. The origin of ensemble kinematic hardening with multiple back stress components due to interactions of hard and soft subsystems emerges naturally.

Reprinted from with permission [86].

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Jaynes ET (1957) Information theory and statistical mechanics. Phys Rev 106:620–630. https://doi.org/10.1103/PhysRev.106.620

Jaynes ET (1957) Information theory and statistical mechanics. II. Phys Rev 108:171–190. https://doi.org/10.1103/PhysRev.108.171

Jaynes ET (1980) The minimum entropy production principle. Ann Rev Phys Chem 31:579–601. https://doi.org/10.1146/annurev.pc.31.100180.003051

Sutton C, Levchenko SV (2020) First-principles atomistic thermodynamics and configurational entropy. Front Chem 8:757. https://doi.org/10.3389/fchem.2020.00757

Liu ZK, Li B, Lin H (2019) Multiscale entropy and its implications to critical phenomena, emergent behaviors, and information. J Phase Equilib Diffus 40(4):508–521. https://doi.org/10.1007/s11669-019-00736-w

Liu ZK, Wang Y, Shang SL (2022) Zentropy theory for positive and negative thermal expansion. J Phase Equilib Diffus 43:598–605. https://doi.org/10.1007/s11669-022-00942-z

Nadai A (1963) Theory of flow and fracture of solids, vol 2. McGraw-Hill, New York, pp 96–105

Chung K, Richmond O (1993) A deformation theory of plasticity based on minimum work paths. Int J Plast 9(8):907–920. https://doi.org/10.1016/0749-6419(93)90057-W

Dewar RC (2009) Maximum entropy production as an inference algorithm that translates physical assumptions into macroscopic predictions: don’t shoot the messenger. Entropy 11:931–944. https://doi.org/10.3390/e11040931

Chakrabarti CG, Ghosh K (2010) Maximum-entropy principle: ecological organization and evolution. J Biol Phys 36:175–183. https://doi.org/10.1007/s10867-009-9170-z

Yukalov VI, Sornette D (2014) Self-organization in complex systems as decision making. Adv Complex Syst 17:1450016. https://doi.org/10.1142/S0219525914500167

Leyson GPM, Curtin WA (2013) Friedel vs. Labusch: the strong/weak pinning transition in solute strengthened metals. Philos Mag 93(19):2428–2444. https://doi.org/10.1080/14786435.2013.776718

Zirkle T, Zhu T, McDowell DL (2023) Multiscale modeling of hydrogen-affected crack tip damage using a fully coupled chemomechanical crystal plasticity framework for austenitic stainless steel. Int J Multiscale Comput Eng 21(2):21–65. https://doi.org/10.1615/IntJMultCompEng.2022042488

Mareschal M (1984) Long range correlations in a non equilibrium system. In: Vidal C, Pacault A (eds) Non-equilibrium dynamics in chemical systems. Springer series in synergetics, vol 27. Springer, Berlin. https://doi.org/10.1007/978-3-642-70196-2_31

Sudmans M, Stricker M, Weygand D, Hochrainer T, Schulz K (2019) Dislocation multiplication by cross-slip and glissile reaction in a dislocation based continuum formulation of crystal plasticity. J Mech Phys Solids 132:103695. https://doi.org/10.1016/j.jmps.2019.103695

Stricker M, Weygand D (2015) Dislocation multiplication mechanisms—glissile junctions and their role on the plastic deformation at the microscale. Acta Mater 99:130–139. https://doi.org/10.1016/j.actamat.2015.07.073

Cottrell A (2009) Strain hardening at different temperatures. Philos Mag Lett 89(1):19–22. https://doi.org/10.1080/09500830802448569

Prigogine I (1947) Etude Thermodynamique des Phénoménes Irréversibles. Desoer, Liége

Patra A, McDowell DL (2012) Crystal plasticity-based constitutive modeling of irradiated bcc structures. Philos Mag 92(7):861–887. https://doi.org/10.1080/14786435.2011.634855

Castelluccio GM, McDowell DL (2017) Mesoscale cyclic crystal plasticity with dislocation substructures. Int J Plast 98:1–26. https://doi.org/10.1016/j.ijplas.2017.06.002

Ma A, Roters F, Raabe D (2006) A dislocation density based constitutive model for crystal plasticity FEM including geometrically necessary dislocations. Acta Mater 54:2169–2179. https://doi.org/10.1016/j.actamat.2006.01.005

Wang AJ, Kumar RS, Shenoy MM, McDowell DL (2006) Microstructure-based multiscale constitutive modeling of γ–γʹ nickel-base superalloys. Int J Multiscale Comput Eng 4(5–6):663–692. https://doi.org/10.1615/IntJMultCompEng.v4.i5-6.70

Roters F, Diehl M, Shanthraj P, Eisenlohr P, Reuber C, Wong SL, Maiti T, Ebrahimi A, Hochrainer T, Fabritius HO, Nikolov S, Friák M, Fujita N, Grilli N, Janssens KGF, Jia N, Kok PJJ, Ma D, Meier F, Werner E, Stricker M, Weygand E, Raabe D (2019) DAMASK—The Düsseldorf Advanced Material Simulation Kit for modeling multi-physics crystal plasticity, thermal, and damage phenomena from the single crystal up to the component scale. Comput Mater Sci 158(15):420–478. https://doi.org/10.1016/j.commatsci.2018.04.030

Evers LP, Brekelmans WAM, Geers MGD (2004) Scale dependent crystal plasticity framework with dislocation density and grain boundary effects. Int J Solids Struct 41(18–19):5209–5230. https://doi.org/10.1016/j.ijsolstr.2004.04.021

Dunne FPE, Kiwanuka R, Wilkinson AJ (2012) Crystal plasticity analysis of micro-deformation, lattice rotation and geometrically necessary dislocation density. Proc R Soc A 468:2509–2531. https://doi.org/10.1098/rspa.2012.0050

Patra A, Chaudhary S, Pai N, Ramgopal T, Khandelwal S, Rao A, McDowell DL (2023) ρ-CP: open source dislocation density based crystal plasticity framework for simulating thermomechanical deformation. Comput Mater Sci 224:112182. https://doi.org/10.1016/j.commatsci.2023.112182

Rice JR (1971) Inelastic constitutive relations for solids: an internal-variable theory and its application to metal plasticity. J Mech Phys Solids 9:433–455. https://doi.org/10.1016/0022-5096(71)90010-X

Patra A, Zhu T, McDowell DL (2014) Constitutive equations for modeling non-Schmid effects in single crystal bcc-Fe at low and ambient temperatures. Int J Plast 59:1–14. https://doi.org/10.1016/j.ijplas.2014.03.016

Kalidindi SR, Bronkhorst CA, Anand L (1992) Crystallographic texture evolution in bulk deformation processing of fcc metals. J Mech Phys Solids 40(3):537–569. https://doi.org/10.1016/0022-5096(92)80003-9

Cuitiño AM, Ortiz M (1993) Computational modelling of single crystals. Modell Simul Mater Sci Eng 1(3):225–263. https://doi.org/10.1088/0965-0393/1/3/001

Busso EP, Cailletaud G (2005) On the selection of active slip systems in crystal plasticity. Int J Plast 21(11):2212–2231. https://doi.org/10.1016/j.ijplas.2005.03.019

Kocks UF, Argon AS, Ashby MF (1975) Thermodynamics and kinetics of slip. In: Chalmers B, Christian JW, Massalski TB (eds) Progress in materials science, vol 19. Pergamon Press, Oxford

Narayanan S, McDowell DL, Zhu T (2014) Crystal plasticity model for bcc iron atomistically informed by kinetics of correlated kinkpair nucleation on screw dislocation. J Mech Phys Solids 65:54–68. https://doi.org/10.1016/j.jmps.2014.01.004

Chen D, Costello LL, Geller CB, Zhu T, McDowell DL (2019) Atomistic modeling of dislocation cross-slip in nickel using free-end nudged elastic band method. Acta Mater 168:426–447. https://doi.org/10.1016/j.actamat.2019.02.035

Zirkle T, Costello L, McDowell DL (2021) Crystal plasticity modeling of hydrogen and hydrogen-related defects in initial yield and plastic flow of single crystal stainless steel 316L. Metall Mater Trans A 52:1–17. https://doi.org/10.1007/s11661-021-06357-8

Peirce D, Asaro RJ, Needleman A (1983) Material rate dependence and localized deformation in crystalline solids. Acta Metall 31(12):1951–1976. https://doi.org/10.1016/0001-6160(83)90014-7

Chen W, Viosin T, Zhang Y, Florien JB, Spadaccini CM, McDowell DL, Zhu T, Way YM (2019) Microscale residual stresses in additively manufactured stainless steel. Nat Commun 10:4338. https://doi.org/10.1038/s41467-019-12265-8

Hennessey C, Castelluccio GM, McDowell DL (2017) Sensitivity of polycrystal plasticity to slip system kinematic hardening laws for Al 7075–T6. Mater Sci Eng A 687:241–248. https://doi.org/10.1016/j.msea.2017.01.070

Sobie C, Capolungo L, McDowell DL, Martinez E (2017) Modal analysis of dislocation vibration and reaction attempt frequency. Acta Mater 134:203–210. https://doi.org/10.1016/j.actamat.2017.02.005

Sobie C, McDowell DL, Martinez E, Capolungo L (2017) Thermal activation of dislocations in large scale obstacle bypass. J Mech Phys Solids 105:150–160. https://doi.org/10.1016/j.jmps.2017.05.003

Arsenault RJ, Patu S, Esterling DM (1989) Computer simulation of solid solution strengthening in fcc alloys: part I. Friedel and Mott limits. Metall Trans A 20:1411–1418. https://doi.org/10.1007/BF02665498

Nabarro FRN (1977) The theory of solution hardening. Philos Mag J Theor Exp Appl Phys 8(35):613–622. https://doi.org/10.1080/14786437708235994

Nabarro FRN (1985) Thermally activated dislocation glide in moderately concentrated solid solutions. Philos Mag B 52(3):785–793. https://doi.org/10.1080/13642818508240636

Hashiguchi K (1989) Subloading surface model in unconventional plasticity. Int J Solids Struct 25(8):917–945. https://doi.org/10.1016/0020-7683(89)90038-3

Clayton JD, McDowell DL, Bammann DJ (2004) A multiscale gradient theory for single crystalline elastoviscoplasticity. Int J Eng Sci 42:427–457. https://doi.org/10.1016/j.ijengsci.2003.08.001

Le KC (2018) Thermodynamic dislocation theory for non-uniform plastic deformations. J Mech Phys Solids 111:157–169. https://doi.org/10.1016/j.jmps.2017.10.022

Roters F, Eisenlohr P, Hantcherli L, Tjahjanto DD, Bieler TR, Raabe D (2010) Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: theory, experiments, applications. Acta Mater 58(4):1152–1211. https://doi.org/10.1016/j.actamat.2009.10.058

Patra A, McDowell DL (2016) Crystal plasticity investigation of the microstructural factors influencing dislocation channeling in a model irradiated bcc material. Acta Mater 100:364–376. https://doi.org/10.1016/j.actamat.2016.03.041

Castelluccio GM, Geller CB, McDowell DL (2018) A rationale for modeling hydrogen effects on plastic deformation across scales in fcc metals. Int J Plast 111:72–84. https://doi.org/10.1016/j.ijplas.2018.07.009

Arsenlis A, Parks DM (2002) Modeling the evolution of crystallographic dislocation density in crystal plasticity. J Mech Phys Solids 50(9):1979–2009. https://doi.org/10.1016/S0022-5096(01)00134-X

Essman U, Mughrabi H (1979) Annihilation of dislocations during tensile and cyclic deformation and limits of dislocation densities. Philos Mag 40:731–756. https://doi.org/10.1080/01418617908234871

Kocks UF, Mecking H (2003) Physics and phenomenology of strain hardening: the FCC case. Prog Mater Sci 48(3):171–273. https://doi.org/10.1016/S0079-6425(02)00003-8

Kubin L, Canova G, Condat M, Devincre B, Pontikis V, Bréchet Y (1992) Dislocation microstructures and plastic flow: a 3D simulation. Solid State Phenom 23:455–472. https://doi.org/10.4028/www.scientific.net/SSP.23-24.455

Zirkle T (2022) Multiscale modeling of hydrogen embrittlement. Dissertation. https://repository.gatech.edu/bitstreams/02060cf5-29ce-44fd-a7a5-2fa7e01f6aaa/download Accessed 12 Jul 2023

Wang Y, Cai W (2023) Stress-dependent activation entropy in thermally activated cross-slip of dislocations. PNAS 120(34):e2222039120. https://doi.org/10.1073/pnas.2222039120

Sills RB, Kuykendall WP, Aghaei A, Cai W (2016) Fundamentals of dislocation dynamics simulations. In: Weinberger CR, Tucker GJ (eds) Multiscale materials modeling for nanomechanics. Springer, Cham (ISBN 978-3-319-33478-3)

Racherla V, Bassani JL (2007) Strain burst phenomena in the necking of a sheet that deforms by non-associated plastic flow. Modell Simul Mater Sci Eng 15:S297–S311. https://doi.org/10.1088/0965-0393/15/1/S23

Mayeur J, McDowell DL (2007) A three-dimensional crystal plasticity model for duplex Ti–6Al–4V. Int J Plast 23(9):1457–1485. https://doi.org/10.1016/j.ijplas.2006.11.006

Zhang M, Zhang J, McDowell DL (2007) Microstructure-based crystal plasticity modeling of cyclic deformation of Ti–6Al–4V. Int J Plast 23(8):1328–1348. https://doi.org/10.1016/j.ijplas.2006.11.009

Lakshmanan A, Yaghoobi M, Stopka KS, Sundararaghavan V (2022) Crystal plasticity finite element modeling of grain size and morphology effects on yield strength and extreme value fatigue response. J Mater Res Technol 19:3337–3354. https://doi.org/10.1016/j.jmrt.2022.06.075

Picu RC, Li R, Xu Z (2009) Strain rate sensitivity of thermally activated dislocation motion across fields of obstacles of different kind. Mater Sci Eng A 502:164–171. https://doi.org/10.1016/j.msea.2008.10.046

Dong Y, Nogaret T, Curtin W (2010) Scaling of dislocation strengthening by multiple obstacle types. Metall Mater Trans A 41:1954–1960. https://doi.org/10.1007/s11661-010-0229-z

Krempl E (1987) Models of viscoplasticity some comments on equilibrium (back) stress and drag stress. Acta Mech 69:25–42. https://doi.org/10.1007/BF01175712

Follansbee PS, Kocks UF (1988) A constitutive description of the deformation of copper based on the use of the mechanical threshold stress as an ISV. Acta Metall 36(1):81–93. https://doi.org/10.1016/0001-6160(88)90030-2

Follansbee PS (2014) On the definition of state variables for an ISV constitutive model describing metal deformation. Mater Sci Appl 5:603–609. https://doi.org/10.4236/msa.2014.58062

Mróz Z (1967) On the description of anisotropic workhardening. J Mech Phys Solids 15(3):163–175. https://doi.org/10.1016/0022-5096(67)90030-0

Lamba HS (1976) Nonproportional cyclic plasticity. TAM report no. 413, Dept. Theoretical and Applied Mechanics, University of Illinois at Urbana-Champaign. https://www.ideals.illinois.edu/items/120028. Accessed 12 Jul 2023

McDowell DL (1985) A two surface model for transient nonproportional cyclic plasticity: part 2—comparison of theory with experiments. ASME J Appl Mech 52:303–308. https://doi.org/10.1115/1.3169045

McDowell DL (1985) An experimental study of the structure of constitutive equations for nonproportional cyclic plasticity. ASME J Eng Mater Technol 107:307–315. https://doi.org/10.1115/1.3225824

Armstrong P, Frederick C (1966) A mathematical representation of the multiaxial Baushinger effect. In G.E.C.B. report RD/B/N 731

Chaboche JL (1977) Viscoplastic constitutive equations for the description of cyclic and anisotropic behaviour of metals. Bull, de I'Acad. Polonaise des Sciences, Serie Sc. et Techn., 17th Polish conference on mechanics of solids, Szczyrk, vol 25, pp 33–41

Chaboche JL, Roussellier G (1983) On the plastic and viscoplastic constitutive equations- part I: rules developed with internal variable concept. ASME J Press Vessel Technol 105:153–158. https://doi.org/10.1115/1.3264257

Chaboche JL, Roussellier G (1983) On the plastic and viscoplastic constitutive equations- part II: application of the internal variables concepts to the 316 stainless steel. ASME J Press Vessel Technol 105:159–164. https://doi.org/10.1115/1.3264258

Chaboche JL (1983) On the constitutive equations of materials under monotonic or cyclic loadings. La Recherche Aerospatiale 5:31–43

Lemaitre J, Chaboche JL (1990) Mechanics of solid materials. Cambridge University Press, Cambridge

Burlet H, Cailletaud G (1987) Modeling of cyclic plasticity in finite element codes. In: 2nd International conference on constitutive laws for engineering materials: theory and applications. Elsevier, Tucson, pp 1157–1164

Moosbrugger JC, McDowell DL (1990) A rate-dependent bounding surface model with a generalized image point for cyclic nonproportional viscoplasticity. J Mech Phys Solids 38(5):627–656. https://doi.org/10.1016/0022-5096(90)90026-Z

Moosbrugger JC, McDowell DL (1989) On a class of kinematic hardening rules for monproportional cyclic plasticity. ASME J Eng Mater Technol 111(1):87–98. https://doi.org/10.1115/1.3226439

McDowell DL (2010) A perspective on trends in multiscale plasticity. Int J Plast 26(9):1280–1309. https://doi.org/10.1016/j.ijplas.2010.02.008

Meric L, Poubanne P, Cailletaud G (1991) Single crystal modeling for structural calculations: part 1—model presentation. ASME J Eng Mater Technol 113(1):162–170. https://doi.org/10.1115/1.2903374

Keshavarz S, Ghosh S, Reid ACE, Langer SA (2016) A non-Schmid crystal plasticity finite element approach to multi-scale modeling of nickel-based superalloys. Acta Mater 114:106–115. https://doi.org/10.1016/j.actamat.2016.05.016

Ghosh S, Weber G, Keshavarz S (2016) Multiscale modeling of polycrystalline nickel-based superalloys accounting for subgrain microstructures. Mech Res Commun 78(2):34–46. https://doi.org/10.1016/j.mechrescom.2015.12.001

Mughrabi H (1983) Dislocation wall and cell structures and long-range internal stresses in deformed metal crystals. Acta Metall 31(9):1367–1379. https://doi.org/10.1016/0001-6160(83)90007-X

Feaugas X (1999) On the origin of the tensile flow stress in the stainless steel AISI 316L at 300 K: back stress and effective stress. Acta Mater 47(13):3617–3632. https://doi.org/10.1016/S1359-6454(99)00222-0

El-Awady J (2015) Unravelling the physics of size-dependent dislocation-mediated plasticity. Nat Commun 6:5926. https://doi.org/10.1038/ncomms6926

Zirkle T, Zhu T, McDowell DL (2021) Micromechanical crystal plasticity back stress evolution within fcc dislocation substructure. Int J Plast 146:103082. https://doi.org/10.1016/j.ijplas.2021.103082

Kang G, Liu Y, Dong Y, Gao Q (2011) Uniaxial ratcheting behaviors of metals with different crystal structures or values of fault energy: macroscopic experiments. J Mater Sci Technol 27(5):453–459. https://doi.org/10.1016/S1005-0302(11)60090-X

McDowell DL, Ghosh S, Kalidindi SR (2011) Representation and computational structure-property relations of random media. JOM 63(3):45–51. https://doi.org/10.1007/s11837-011-0045-y

Ohno N, Wang JD (1993) Kinematic hardening rules with critical state of dynamic recovery, part I: formulation and basic features for ratchetting behavior. Int J Plast 9(3):375–390. https://doi.org/10.1016/0749-6419(93)90042-O

Jiang Y, Sehitoglu H (1996) Modeling of cyclic ratchetting plasticity, part I: development of constitutive relations. ASME J Appl Mech 63(3):720–725. https://doi.org/10.1115/1.2823355

Kubin LP (1993) Dislocation patterning. In: Cahn RW, Haasen P, Kramer EJ (eds) Materials science and technology. Wiley, Hoboken, pp 137–190

Molinari A, Ravichandran G (2005) Constitutive modeling of high-strain-rate deformation in metals based on the evolution of an effective microstructural length. Mech Mater 37(7):737–752. https://doi.org/10.1016/j.mechmat.2004.07.005

Kuhlmann-Wilsdorf D (1989) Theory of plastic deformation: properties of low energy dislocation structures. Mater Sci Eng A 113:1–41. https://doi.org/10.1016/0921-5093(89)90290-6

Hughes DA, Hansen N (1997) High angle boundaries formed by grain subdivision mechanisms. Acta Mater 45(9):3871–3886. https://doi.org/10.1016/S1359-6454(97)00027-X

Hughes DA, Liu Q, Chrzan DC, Hansen N (1997) Scaling of microstructural parameters: misorientations of deformation induced boundaries. Acta Mater 45(1):105–112. https://doi.org/10.1016/S1359-6454(96)00153-X

Butler GC, McDowell DL (1998) Polycrystal constraint and grain subdivision. Int J Plast 14(8):703–717. https://doi.org/10.1016/S0749-6419(98)00018-7

Ortiz M, Repetto EA (1999) Nonconvex energy minimization and dislocation structures in ductile single crystals. J Mech Phys Solids 47:397–462. https://doi.org/10.1016/S0022-5096(97)00096-3

Ortiz M, Repetto EA, Stainier L (2000) A theory of subgrain dislocation structures. J Mech Phys Solids 48:2077–2114. https://doi.org/10.1016/S0022-5096(99)00104-0

Carstensen C, Hackl K, Mielke A (2002) Non-convex potentials and microstructures in finite-strain plasticity. Proc R Soc Lond A 458:299–317. https://doi.org/10.1098/rspa.2001.086

Conti S, Ortiz M (2005) Dislocation microstructures and the effective behavior of single crystals. Arch Ration Mech Anal 176:103–147. https://doi.org/10.1007/s00205-004-0353-2

Hackl K, Hoppe U, Kochmann DM (2012) Generation and evolution of inelastic microstructures an overview. GAMM-Mitt 35(1):91–106. https://doi.org/10.1002/gamm.201210007

Song H, Gunkelmann N, Po G, Sandfeld S (2021) Data-mining of dislocation microstructures: concepts for coarse-graining of internal energies. Modell Simul Mater Sci Eng 29:035005. https://doi.org/10.1088/1361-651X/abdc6b

Acknowledgements

This effort is conducted in tribute to the legacy of collaborations and contributions made by Hussein Zbib in modeling and understanding multiscale aspects of dislocation plasticity using methods and tools ranging from DDD to crystal plasticity to generalized continua descriptions. Support of the Carter N. Paden, Jr. Distinguished Chair in Metals Processing is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

This work is the sole intellectual product of the author.

Corresponding author

Ethics declarations

Conflict of interest

No conflicts of interest exist and the author declares he has no competing interests.

Ethical approval

Not applicable.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

McDowell, D.L. Nonequilibrium statistical thermodynamics of thermally activated dislocation ensembles: part 2—ensemble evolution toward correlation of enthalpy barriers. J Mater Sci 59, 5126–5160 (2024). https://doi.org/10.1007/s10853-023-09142-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09142-7