Abstract

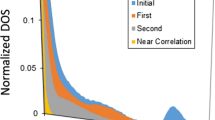

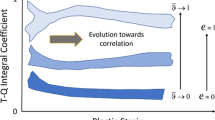

This three-part paper lends new insight into the interpretation of internal state variable (ISV) theory and fundamentals of the behavior of thermally activated dislocation ensembles. We formally define important physical concepts undergirding ISV theory such as configurational subsystems (e.g., individual grains or phases), constrained local equilibrium, and thermally activated dislocation reactions in the context of crystal plasticity and then implement these concepts within a nonequilibrium statistical thermodynamics framework. The primal importance of the Gibbs free energy barrier to dislocation reactions within each subsystem is emphasized since the enthalpy barriers are affected by local constraint and resulting long-range and short-range athermal internal stresses acting within subsystems. Kinetic and kinematic aspects of individual dislocation reactions are defined. The role of athermal internal stresses in stabilizing the positions of dislocations between barriers is acknowledged by the formal identification of the anelastic deformation, along with its role in contributing to thermal dissipation. Thermal and configurational intrinsic entropy change that contribute to the change of Gibbs free energy as a driving force for reactions are formally introduced in the same way as in first principles methods and are based on probability of pending dislocation reactions at each step. We distinguish equilibrium thermodynamics up to the saddle point of reactions, for which change of both configurational and thermal entropy applies, from post-saddle point extended glide of dislocations, which couples with the thermal bath via dispersive phonon dynamics. We write subsystem and ensemble relations for intrinsic entropy production. The concept of “degree-of-correlation” of the enthalpy barriers of thermally activated dislocation processes is introduced at both the subsystem level and across the overall ensemble of subsystems, based on the ratio of the weighted average enthalpy barrier to the maximum (rate-limiting) enthalpy barrier. It is argued that nonequilibrium trajectories progressively move toward correlated behavior of the ensemble by virtue of internal stress redistribution among interacting subsystems that are favorable and unfavorable to reactions. The degree-of-correlation is a many-body concept involving populations of dislocations within and among various configurational subsystems.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Gibbs GB (1965) The Thermodynamics of thermally-activated dislocation glide. Physica Status Solidi (b) 10(2):507–512. https://doi.org/10.1002/pssb.2220100212

Frank W (1968) Thermally activated dislocation motion in a solid containing a multiple spectrum of dislocation obstacles. Phys Stat Sol 06:197–206. https://doi.org/10.1002/pssb.19680260120

Hirth JP, Nix WD (1969) An analysis of the thermodynamics of dislocation glide. Phys Stat Sol 35:177–188. https://doi.org/10.1002/pssb.19690350116

Conrad H (1964) Thermally activated deformation of metals. J Metals 16:582–588. https://doi.org/10.1007/BF03378292

Kocks UF, Argon AS, Ashby MF (1975) Thermodynamics and kinetics of slip. In: Chalmers B, Christian JW, Massalski TB (eds) Progress in materials science, vol 19. Pergamon Press, Oxford.

Coleman BD, Gurtin ME (1967) Thermodynamics with ISVs. J Chem Phys 47:597–613. https://doi.org/10.1063/1.1711937

Coleman BD, Noll W (1963) The thermodynamics of elastic materials with heat conduction and viscosity. Arch Ration Mech Anal 13(1):167–178. https://doi.org/10.1007/BF01262690

Kestin J, Rice JR (1970) Paradoxes in the application of thermo-dynamics to strained solids. In: Stuart EB, Gal Or B, Brainard AJ (eds) A critical review of thermodynamics. Mono-Book Corp., Baltimore, pp. 275–298.

Chaboche JL (1977) Viscoplastic constitutive equations for the description of cyclic and anisotropic behaviour of metals. Bull, de I’Acad. Polonaise des Sciences, Serie Sc. et Techn.. In: 17th Polish Conf. on Mechanics of Solids. Szczyrk 25:33–41

Germain P, Nguyen QS, Suquet P (1983) Continuum thermodynamics. ASME J Appl Mech 50:1010. https://doi.org/10.1115/1.3167184

Chaboche JL, Roussellier G (1983) On the plastic and viscoplastic constitutive equations—part I: rules developed with internal variable concept. ASME J Pressure Vessel Techn 105:153–158. https://doi.org/10.1115/1.3264257

Chaboche JL, Roussellier G (1983) On the plastic and viscoplastic constitutive equations—part II: application of the internal variables concepts to the 316 Stainless Steel. ASME J Pressure Vessel Techn 105:159–164. https://doi.org/10.1115/1.3264258

Chaboche JL (1983) On the constitutive equations of materials under monotonic or cyclic loadings. La Recherche Aerospatiale 5:31–43

Lemaitre J, Chaboche JL (1990) Mechanics of solid materials. Cambridge University Press, Cambridge

Muschik W (1993) Fundamentals of nonequilibrium thermodynamics. In Muschik W (ed) non-equilibrium thermodynamics with applications to solids, CISM courses and lectures No. 336. In: Mushik W (ed) International centre for mechanical sciences.Springer, New York, pp 1–63.

McDowell DL (2005) ISV theory. In: Yip S. (ed) Handbook of materials modeling. Springer, Dordrecht. https://doi.org/10.1007/978-1-4020-3286-8_58

Horstemeyer MF, Bammann DJ (2010) Historical review of ISV theory for inelasticity. Int J Plast 26(9):1310–1334. https://doi.org/10.1016/j.ijplas.2010.06.005

Chaboche JL (1993) Cyclic viscoplastic constitutive equations, part I: a thermodynamically consistent formulation. ASME J Appl Mech 60:813–821. https://doi.org/10.1115/1.2900988

Chaboche JL (1993) Cyclic viscoplastic constitutive equations, part II: stored energy—comparison between models and experiments. ASME J Appl Mech 60:822–828. https://doi.org/10.1115/1.2900990

Anderson PM, Hirth JP, Lothe J (2017) Theory of dislocations, 3rd edn. Cambridge University Press, Cambridge

Vilar JJG, Rubi JM (2001) Thermodynamics “beyond” local equilibrium. PNAS 98(20):11081–11084. https://doi.org/10.1073/pnas.191360398

Liu ZK, Li B, Lin H (2019) Multiscale entropy and its implications to critical phenomena, emergent behaviors, and information. J Phase Equilib Diffus 40(4):508–521. https://doi.org/10.1007/s11669-019-00736-w

Sutton C, Levchenko SV (2020) First-principles atomistic thermodynamics and configurational entropy. Front Chem 8:757. https://doi.org/10.3389/fchem.2020.00757

Hiratani M, Zbib HM, Khaleel MA (2003) Modeling of thermally activated dislocation glide and plastic flow through local obstacles. Int J Plast 19(9):1271–1296. https://doi.org/10.1016/S0749-6419(02)00016-5

Zbib HM, Rhee M, Hirth JP (1998) On plastic deformation and the dynamics of 3D dislocations. Int J Mech Sci 40(2–3):113–127. https://doi.org/10.1016/S0020-7403(97)00043-X

Amodeo RJ, Ghoniem NM (1990) Dislocation dynamics. I. A proposed methodology for micromechanics. Phys Rev B 41:6958. https://doi.org/10.1103/PhysRevB.41.6958

Martınez E, Mariana J, Arsenlis A, Victoria M, Perlado JM (2008) Atomistically informed dislocation dynamics in fcc crystals. J Mech Phys Solids 56:869–895. https://doi.org/10.1016/j.jmps.2007.06.014

Devincre B, Hoc T, Kubin L (2008) Dislocation mean free paths and strain hardening of crystals. Science 320(5884):1745–1748. https://doi.org/10.1126/science.1156101

Maugin GA (2011) Configurational forces: thermomechanics, physics, mathematics, and numerics. Taylor and Francis, CRC Press, Boca Raton

Gurtin M (2000) Configurational forces as basic concepts of continuum physics. Appl Math Sci, 137.

Fried E, Gurtin ME (2005) The unifying nature of the configurational force balance. In: Steinmann, P., Maugin, G.A. (eds) Mechanics of material forces. Adv Mech Math, 11. Springer, Boston. https://doi.org/10.1007/0-387-26261-X_3

Patra A, McDowell DL (2012) Crystal plasticity-based constitutive modeling of irradiated bcc structures. Philos Mag 92(7):861–887. https://doi.org/10.1080/14786435.2011.634855

Chaboche JL (1997) Thermodynamic formulation of constitutive equations and application to the viscoplasticity and viscoelasticity of metals and polymers. Int J Solids Struct 34(18):2239–2254. https://doi.org/10.1016/S0020-7683(96)00162-X

Zirkle T, Costello L, McDowell DL (2021) Crystal plasticity modeling of hydrogen and hydrogen-related defects in initial yield and plastic flow of single crystal Stainless Steel 316L. Metall Mater Trans A 52:1–17. https://doi.org/10.1007/s11661-021-06357-8

Mura T (1987) Micromechanics of defects in solids. In: Mechanics of elastic and inelastic solids (MEIS, volume 3). Springer, Dordrecht.

Qu J, Cherkaoui M (2006) Fundamentals of micromechanics of solids. Wiley, Hoboken, New Jersey

Rice JR (1971) Inelastic constitutive relations for solids: an internal-variable theory and its application to metal plasticity. J Mech Phys Solids 9:433–455. https://doi.org/10.1016/0022-5096(71)90010-X

Rice JR (1975) Continuum mechanics and thermodynamics of plasticity in relation to microscale deformation mechanisms. In: Argon AS (ed) Constitutive equations in plasticity. MIT Press, Cambridge, pp 23–79.

Mesarovic SD, Baskaran R, Panchenko A (2010) Thermodynamic coarse-graining of dislocation mechanics and the size-dependent continuum crystal plasticity. J Mech Phys Solids 58(3):311–329. https://doi.org/10.1016/j.jmps.2009.12.002

Meyers MA, Ashworth E (1982) A model for the effect of grain size on yield stress of metals. Phil Mag A 46(5):737–759. https://doi.org/10.1080/01418618208236928

Mughrabi H (1983) Dislocation wall and cell structures and long-range internal stresses in deformed metal crystals. Acta Metall 31(9):1367–1379. https://doi.org/10.1016/0001-6160(83)90007-X

Austin RA, McDowell DL (2011) A dislocation-based constitutive model for viscoplastic deformation of fcc metals at very high strain rates. Int J Plast 27(1):1–24. https://doi.org/10.1016/j.ijplas.2010.03.002

Lloyd JT, Clayton JD, Becker RC, McDowell DL (2014) Simulation of shock wave propagation in single crystal and polycrystalline aluminum. Int J Plast 60:118–144. https://doi.org/10.1016/j.ijplas.2014.04.012

Fan H, Wang Q, El-Awady J, Raabe D, Zaiser M (2021) Strain rate dependency of dislocation plasticity. Nat Commun 12:1845. https://doi.org/10.1038/s41467-021-21939-1

Tanner AB (1998) Modeling Temperature and strain rate history effects in OFHC Cu. https://apps.dtic.mil/sti/pdfs/ADA345850.pdf. Accessed July 12, 2023 Dissertation

Lea LJ, Jardine AP (2018) Characterisation of high rate plasticity in the uniaxial deformation of high purity copper at elevated temperatures. Int J Plast 102:41–52. https://doi.org/10.1016/j.ijplas.2017.11.006

Henkelman G, Uberuaga BP, Jonsson H (2000) A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J Chem Phys 113:9901–9904. https://doi.org/10.1063/1.1329672

Zhu T, Li J, Yip S (2013) Atomistic reaction pathway sampling: the nudged elastic band method and nanomechanics applications. In: Espinosa HD, Bao G (eds) Nano and cell mechanics: fundamentals and frontiers, vol 1, Chapter 12. Wiley, Chichester.

Narayanan S, McDowell DL, Zhu T (2014) Crystal plasticity model for bcc iron atomistically informed by kinetics of correlated kinkpair nucleation on screw dislocation. J Mech Phys Solids 65:54–68. https://doi.org/10.1016/j.jmps.2014.01.004

Chen D, Costello LL, Geller CB, Zhu T, McDowell DL (2019) Atomistic modeling of dislocation cross-slip in nickel using free-end nudged elastic band method. Acta Mater 168:426–447. https://doi.org/10.1016/j.actamat.2019.02.035

Sobie C, Capolungo L, McDowell DL, Martinez E (2017) Modal analysis of dislocation vibration and reaction attempt frequency. Acta Mater 134:203–210. https://doi.org/10.1016/j.actamat.2017.02.005

Xiong L, McDowell DL, Chen Y (2015) Concurrent atomistic-continuum simulations of dislocation-void interactions in fcc crystals. Int J Plasticity 65:33–42. https://doi.org/10.1016/j.ijplas.2014.08.002

Sharpa TA, Thomas SL, Cubuk ED, Schoenholz SS, Srolovitz DJ, Liu AJ (2018) Machine learning determination of atomic dynamics at grain boundaries. PNAS 114(43):10943–10947. https://doi.org/10.1073/pnas.1807176115

Granato A, Lucke K, Schlipf J, Teutonico L (1964) Entropy factors for thermally activated unpinning of dislocations. J Appl Phys 35(9):2732–2745. https://doi.org/10.1063/1.1713833

Sobie C, McDowell DL, Martinez E, Capolungo L (2017) Thermal activation of dislocations in large scale obstacle bypass. J Mech Phys Solids 105:150–160. https://doi.org/10.1016/j.jmps.2017.05.003

Saroukhani S, Nguyen LD, Leung KWK, Singh CV, Warner DH (2016) Harnessing atomistic simulations to predict the rate at which dislocations overcome obstacles. J Mech Phys Solids 90:203–214. https://doi.org/10.1016/j.jmps.2016.02.016

Meyer W, Neldel H (1937) Relation between the energy constant and the quantity constant in the conductivity–temperature formula of oxide semiconductors. Z Tech Phys 12:588

Dyre JC (1986) A phenomenological model for the Meyer-Neldel rule. J Phys C: Solid State Phys 19:5655–5664. https://doi.org/10.1088/0022-3719/19/28/016

Ryu S, Kang K, Cai W (2011) Predicting the dislocation nucleation rate as a function of temperature and stress. J Mater Res 26:2335–2354. https://doi.org/10.1557/jmr.2011.275

Esteban-Manzanares G, Santos-Güemes R, Papadimitriou I, Martínez E, LLorca J (2020) Influence of the stress state on the cross-slip free energy barrier in Al: an atomistic investigation. Acta Mater 184:109–119. https://doi.org/10.1016/j.actamat.2019.10.055

Sursaeva VG, Protasova SG, Straumal BB (2001) Meyer-Neldel rule for the kinetic properties of grain and interphase boundaries. Defect and Diffusion Forum, Vols. 192–193, Scitec Publications, Switzerland, pp 15–26.

Sapunov VN, Saveljev EA, Voronov MS, Valtiner M, Linert W (2021) The basic theorem of temperature-dependent processes. Thermo 1:45–60. https://doi.org/10.3390/thermo1010004

Saroukhani S, Warner DH (2017) Investigating dislocation motion through a field of solutes with atomistic simulations and reaction rate theory. Acta Mater 128:77–86. https://doi.org/10.1016/j.actamat.2017.02.001

Wang Y, Cai W (2023) Stress-dependent activation entropy in thermally activated cross-slip of dislocations. PNAS 120(34):e2222039120. https://doi.org/10.1073/pnas.2222039120

Friedel J (1964) Dislocations. In: Smoluchowski R, Kurti N (eds) International series of monographs on solid state physics, 1st edn. Elsevier Science, Netherlands.

Xu Z, Picu RC (2007) Thermally activated motion of dislocations in fields of obstacles: the effect of obstacle distribution. Phys Rev B 76:094112. https://doi.org/10.1103/PhysRevB.76.094112

Cho J, Molinari JF, Anciaux G (2017) Mobility law of dislocations with several character angles and temperatures in fcc aluminum. Int J Plast 90:66–75. https://doi.org/10.1016/j.ijplas.2016.12.004

Chu K, Foster ME, Sills RB, Zhou X, Zhu T, McDowell DL (2020) Temperature and composition dependent mobility of screw dislocations in austenitic stainlesss steels from large-scale molecular dynamics. NPJ Comput Mater 6:179. https://doi.org/10.1038/s41524-020-00452-x

Benzerga AA, Shaver NF (2006) Scale dependence of mechanical properties of single crystals under uniform deformation. Scripta Mater 54:1937–1941. https://doi.org/10.1016/j.scriptamat.2006.02.003

Sudmans M, Stricker M, Weygand D, Hochrainer T, Schulz K (2019) Dislocation multiplication by cross-slip and glissile reaction in a dislocation based continuum formulation of crystal plasticity. J Mech Phys Solids 132:103695. https://doi.org/10.1016/j.jmps.2019.103695

Stricker M, Weygand D (2015) Dislocation multiplication mechanisms—glissile junctions and their role on the plastic deformation at the microscale. Acta Mater 99:130–139. https://doi.org/10.1016/j.actamat.2015.07.073

Stricker M, Sudmans M, Schulz K, Hochrainer T, Weygand D (2018) Dislocation multiplication in Stage II deformation of fcc multi-slip single crystals. J Mech Phys Solids 119:319–333. https://doi.org/10.1016/j.jmps.2018.07.003

Labusch R (1988) Cooperative effects in alloy hardening. Czech J Phys B 38:474–481. https://doi.org/10.1007/BF01597457

Ardell AJ (1994) Intermetallics and Precipitates and Dispersoids in High-Strength Alloys. In: Westbrook JH, Fleischer RL (eds) Intermetallic compounds, vol 2, Principles and Practice.Wiley, New york, pp. 257–286.

Koizumi H, Kirchner HOK (2009) Energy flow around a moving dislocation. IOP Conf. Ser.: Mater. Sci. Eng. 3:012028. https://doi.org/10.1088/1757-899X/3/1/012028

Mesarovic SD (2005) Energy, configurational forces and characteristic lengths associated with the continuum description of geometrically necessary dislocations. Int J Plast 21:1855–1889. https://doi.org/10.1016/j.ijplas.2004.09.002

Xu S, Che R, Xiong L, Chen Y, McDowell DL (2015) A quasistatic implementation of the concurrent atomistic-continuum method for fcc crystals. Int J Plast 72:91–126. https://doi.org/10.1016/j.ijplas.2015.05.007

Xu S, Xiong L, Chen Y, McDowell DL (2016) Edge dislocations bowing out from a row of collinear obstacles in Al. Scripta Mater 123:135–139. https://doi.org/10.1016/j.scriptamat.2016.06.018

Li D, Wagoner RH (2021) The nature of yielding and anelasticity in metals. Acta Mater 206:116625. https://doi.org/10.1016/j.actamat.2021.116625

McDowell DL (2008) Viscoplasticity of heterogeneous metallic materials. Mater Sci Eng R Rep 62(3):67–123. https://doi.org/10.1016/j.mser.2008.04.003

Mareau C, Favier V, Weber B, Galtie A, Berveiller M (2012) Micromechanical modeling of the interactions between the microstructure and the dissipative deformation mechanisms in steels under cyclic loading. Int J Plast 32–33:106–120. https://doi.org/10.1016/j.ijplas.2011.12.004

Sgobba S, Parrini L, Künzi HU, Ilschner B (1994) Analysis of the anelastic creep of Al and two Al-Cu alloys. J Alloy Compd 211–212:608–612. https://doi.org/10.1016/0925-8388(94)90578-9

San Juan J, No ML, Schuh CA (2009) Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nat Nanotechnol 4:415–419. https://doi.org/10.1038/nnano.2009.142

Tanimoto H, Sakai S, Mizubayashi H (2004) Anelasticity of nanocrystalline metals. Mater Sci Eng A 370:135–141. https://doi.org/10.1016/j.msea.2003.08.103

Chen Y, Liao X (2016) Mechanical behaviors of semiconductor nanowires In: Dayeh SA, Fontcuberta i Morral A, Jagadish C (eds) Semiconductors and semimetals. Elsevier, Amsterdam, vol 94, Ch 4.

Caron A, Kawashima A, Fecht HJ, Louzguine-Luzguin DV, Inoue A (2011) On the anelasticity and strain induced structural changes in a Zr-based bulk metallic glass. Appl Phys Lett 99(111):171907. https://doi.org/10.1063/1.3655999

Castelluccio GM, McDowell DL (2017) Mesoscale cyclic crystal plasticity with dislocation substructures. Int J Plast 98:1–26. https://doi.org/10.1016/j.ijplas.2017.06.002

Zirkle T, McDowell DL (2022) Analysis of monotonic and cyclic crack tip plasticity for a stationary crack tip in a fcc crystal. Comput Mater Sci 202:110954. https://doi.org/10.1016/j.commatsci.2021.110954

Pelloux RMN (1970) Crack extension by alternating shear. Eng Fract Mech 1:697–704. https://doi.org/10.1016/0013-7944(70)90008-1

Feaugas X (1999) On the origin of the tensile flow stress in the Stainless Steel AISI 316L at 300 K: back stress and effective stress. Acta Mater 47(13):3617–3632. https://doi.org/10.1016/S1359-6454(99)00222-0

Dickson J, Boutin J, Handfield L (1984) A comparison of two simple methods for measuring cyclic internal and effective stresses. Mater Sci Eng 64(1):L7–L11. https://doi.org/10.1016/0025-5416(84)90083-1

Hughes DA, Hansen N (1997) High angle boundaries formed by grain subdivision mechanisms. Acta Mater 45(9):3871–3886. https://doi.org/10.1016/S1359-6454(97)00027-X

Hughes DA, Liu Q, Chrzan DC, Hansen N (1997) Scaling of microstructural parameters: misorientations of deformation induced boundaries. Acta Mater 45(1):105–112. https://doi.org/10.1016/S1359-6454(96)00153-X

Butler GC, McDowell DL (1998) Polycrystal constraint and grain subdivision. Int J Plast 14(8):703–717. https://doi.org/10.1016/S0749-6419(98)00018-7

Guvenilir A, Butler GC, Haase JD, McDowell DL, Stock SR (1998) X-ray microbeam quantification of grain subdivision accompanying large deformations of copper. Acta Mater 46(18):6599–6604. https://doi.org/10.1016/S1359-6454(98)00298-5

Clayton J, Schroeter B, Graham S, McDowell DL (2002) Distributions of stretch and rotation in polycrystalline OFHC Cu. ASME J Eng Mater Technol 124(3):302–313. https://doi.org/10.1115/1.1479354

Kostic MM (2020) The second law and entropy misconceptions demystified. Entropy 22:648. https://doi.org/10.3390/e22060648

Gokhale AM (2004) Quantitative Characterization and Representation of Global Microstructural Geometry. In: Vander Voort, GF (ed) ASM handbook, Volume 9: Metallography and Microstructures, pp. 428–447.https://doi.org/10.1361/asmhba0003759

Picu RC, Li R, Xu Z (2009) Strain rate sensitivity of thermally activated dislocation motion across fields of obstacles of different kind. Mater Sci Eng A 502:164–171. https://doi.org/10.1016/j.msea.2008.10.046

Dong Y, Nogaret T, Curtin W (2010) Scaling of dislocation strengthening by multiple obstacle types. Metall Mater Trans A 41:1954–1960. https://doi.org/10.1007/s11661-010-0229-z

Arsenault RJ, Patu S, Esterling DM (1989) Computer simulation of solid solution strengthening in fcc alloys: Part I. Friedel and Mott limits. Metall Trans A 20:1411–1418. https://doi.org/10.1007/BF02665498

Nabarro FRN (1977) The theory of solution hardening. Philos Magaz J Theor Exp App Phys 8(35):613–622. https://doi.org/10.1080/14786437708235994

Leyson GPM, Curtin WA (2013) Friedel vs. Labusch: The strong/weak pinning transition in solute strengthened metals. Philos Magaz 93(19):2428–2444. https://doi.org/10.1080/14786435.2013.776718

Xu S, Xiong L, Chen Y, McDowell DL (2016) An analysis of key characteristics of the Frank-Read source process in fcc metals. J Mech Phys Solids 96:460–476. https://doi.org/10.1016/j.jmps.2016.08.002

Takeuchi S, Edagawa K, Kamimura Y (2021) Theoretical justification of single-ended dislocation-source-controlled deformation of micropillar fcc crystals. Phys Rev Lett 126:155501. https://doi.org/10.1103/PhysRevLett.126.155501

Benzerga AA, Bréchet Y, Needleman A, Van der Giessen E (2005) The stored energy of cold work: predictions from discrete dislocation plasticity. Acta Mater 53(18):4765–4779. https://doi.org/10.1016/j.actamat.2005.07.011

Gurrutxaga-Lerma B, Balint DS, Dini D, Sutton AP (2015) The mechanisms governing the activation of dislocation sources in aluminum at different strain rates. J Mech Phys Solids 84:273–292. https://doi.org/10.1016/j.jmps.2015.08.008

Ziegler H (1977) An introduction to thermomechanics. North-Holland, Amsterdam

Ziegler H (1963) Some extremum principles in irreversible thermodynamics with applications to continuum mechanics. In: Sneddon IN, Hill R (eds) Progress in solid mechanics. North-Holland, Amsterdam, The Netherlands, pp 92–193

Ziegler H, Wehrli C (1987) On a principle of maximal rate of entropy production. J Non-Equilib Thermodyn 12:229–243. https://doi.org/10.1515/jnet.1987.12.3.229

Yang Q, Chen X, Zhou WY (2005) Relationship between normality structure and orthogonality condition. Mech Res Commun 32(5):582–589. https://doi.org/10.1016/j.mechrescom.2005.01.010

Acknowledgements

This work is the culmination of an extended effort to bring together thoughts and ideas developed over the past 30 years in a graduate course developed and taught by the author at Georgia Tech on nonequilibrium kinetics and ISV theory of metals and alloys. This effort is conducted in tribute to the legacy of collaborations and contributions made by Hussein Zbib in modeling and understanding multiscale aspects of dislocation plasticity using methods and tools ranging from DDD to crystal plasticity to generalized continua descriptions. His monumental and insightful contributions to various advanced aspects of modeling dislocations in both continuum and discrete theories are surely of lasting value, along with the memory and example of his gentle and genuine spirit as a friend and colleague. Support of the Carter N. Paden, Jr. Distinguished Chair in Metals Processing is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

This work is the sole intellectual product of the author.

Corresponding author

Ethics declarations

Conflict of Interest

No conflicts of interest exist, and the author declares he has no competing interests.

Ethical Approval

Not applicable.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

McDowell, D.L. Nonequilibrium statistical thermodynamics of thermally activated dislocation ensembles: part 1: subsystem reactions under constrained local equilibrium. J Mater Sci 59, 5093–5125 (2024). https://doi.org/10.1007/s10853-023-09165-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09165-0