Abstract

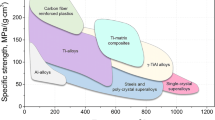

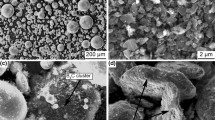

TiB whisker-reinforced Ti2AlNb (TiBw/Ti2AlNb) composites with a network architecture were fabricated by the spark plasma sintering (SPS) technique at the temperature ranging from 950 to 1250 °C with the pressure range of 15–50 MPa for 5–30 min and followed by furnace cooling. The effects of SPS parameters and the volume fraction of TiB2 on the microstructure, densification, phase composition and mechanical properties of the sintered composites were studied in detail. The results revealed that the microstructure of TiBw/Ti2AlNb composites was related to the degree of in situ reaction, which was linked to sintering temperature, time, pressure and the volume fraction of TiB2. The TiBw/Ti2AlNb composite exhibited the highest strength and plasticity at room temperature with the sintering process of 1200 °C/15 min/50 MPa/2.5 vol. % TiB2, and its ultimate tensile strength was nearly 240 MPa higher than that of SPS sintered Ti2AlNb-based alloy. However, its high-temperature mechanical properties were lower than those of SPS sintered Ti2AlNb-based alloy, which is due to the fact that the bonding strength between high-strength TiB whiskers and Ti2AlNb matrix was worse during hot deformation, the interface deboned before fracture, and the strengthening effect of TiBw decreased. Compared with the traditional TiBw-titanium alloys system, this work systematically discussed the influence of various parameters on the microstructure and mechanical properties of the composites under TiBw-Ti2AlNb-based alloys system, which can eventually enrich the application of network architecture in the field of powder metallurgy to improve the mechanical properties of materials and provide guidance for the optimization of process parameters.

Graphical Abstract

Similar content being viewed by others

Data availability

The data generated in this work cannot be shared at this time as it is a part of an ongoing project which is treated as confidential.

References

Banerjee D (1997) The intermetallic Ti2AlNb. Prog Mater Sci 42(1–4):135–158

Boehlert CJ, Majumdar BS, Seetharaman V, Miracle DB (1999) Part I. The microstructural evolution in Ti-Al-Nb O+Bcc orthorhombic alloys. Metall Mater Trans A 30(9):2305–2323

Bu ZQ, Zhang YG, Yang L, Kang JM, Li JF (2022) Effect of cooling rate on phase transformation in Ti2AlNb alloy. J Alloy Compd 893(162364):1–10

Cao DY (2023) An investigation on surface coated continuous flax fiber reinforced natural sandwich composites by vacuum-assisted material extrusion process. Process. https://doi.org/10.13140/RG.2.2.26091.41760

Cao DY (2023) Strength enhancement by polylactic acid (PLA) matrix modification of continuous carbon fiber reinforced composites by material extrusion process. Process. https://doi.org/10.13140/RG.2.2.12669.64480

Cao DY, Malakooti S, Kulkarni VN, Ren Y, Lu H (2021) Nanoindentation measurement of core-skin interphase viscoelastic properties in a sandwich glass composite. Mech Time-Depend Mat 25(3):353–363

Emura S, Araoka A, Hagiwara M (2003) B2 grain size refinement and its effect on room temperature tensile properties of a Ti-22A-27Nb orthorhombic intermetallic alloy. Scripta Mater 48(5):629–634

Emura S, Yang SJ, Hagiwara M (2004) Room-temperature tensile and high-cycle-fatigue strength of fine TiB particulate-reinforced Ti-22Al-27Nb composites. Metall Mater Trans A 35(9):2971–2979

Ezugwu EO, Wang ZM (1997) Titanium alloys and their machinability. J Mater Proc Tech 68:262–274

Fan RL, Wu Y, Chen MH, Xie LS (2020) Relationship among microstructure, mechanical properties and texture of TA32 titanium alloy sheets during hot tensile deformation. Trans Nonferrous Met Soc China 30(4):928–943

Feng HB, Jia DC, Zhou Y (2005) Spark plasma sintering reaction synthesized TiB reinforced titanium matrix composites. Compos A Appl Sci Manuf 36(5):558–563

Feng X, Sui JH, Feng Y, Cai W (2010) Preparation and elevated temperature compressive properties of multi-walled carbon nanotube reinforced Ti composites. Mater Sci Eng A 527(6):1586–1589

Gorsse S, Miracle DB (2003) Mechanical properties of Ti-6Al-4V/TiB composites with randomly oriented and aligned TiB reinforcements. Acta Mater 51(9):2427–2442

Groza JR, Zavaliangos A (2000) Sintering activation by external electrical field. Mater Sci Eng A 287(2):171–177

Hagiwara M, Emura S, Araoka A, Kong BO, Tang F (2003) Enhanced mechanical properties of orthorhombic Ti2AlNb-based intermetallic alloy. Met Mater Int 9(3):265–272

Hall EO (1951) The deformation and ageing of mild steel: II characteristics of the Lüders deformation. Proc Phys Soc B 64:742–747

He YS, Hu R, Luo WZ, He T, Lai YJ, Du YJ, Liu XH (2019) Microstructural evolution and creep deformation behavior of novel Ti-22Al-25Nb-1Mo-1V-1Zr-0.2Si (at.%) orthorhombic alloy. Trans Nonferrous Met Soc China 29(2):313–321

Huang LJ, Geng L, Li AB, Yang FY, Peng HX (2009) In situ TiBw/Ti-6Al-4V composites with novel reinforcement architecture fabricated by reaction hot pressing. Scripta Mater 60(11):996–999

Huang LJ, Geng L, Peng HX, Balasubramaniam K, Wang GS (2011) Effects of sintering parameters on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composites with a novel network architecture. Mater Design 32(6):3347–3353

Huang LJ, Geng L, Peng HX, Kaveendran B (2012) High temperature tensile properties of in situ TiBw/Ti6Al4V composites with a novel network reinforcement architecture. Mater Sci Eng A 534:688–692

Huang LJ, Geng L, Wang B, Wu LZ (2013) Effects of volume fraction on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composites with novel network microstructure. Mater Design 45:532–538

Jia JB, Zhang KF, Jiang SS (2014) Microstructure and mechanical properties of Ti-22Al-25Nb alloy fabricated by vacuum hot pressing sintering. Mater Sci Eng A 616:93–98

Jia L, Li X, Kondoh K, Chen B, Li SF, Umeda JK, Lu ZL (2019) Hybrid effect of TiCp and TiBw co-strengthening Ti matrix composites prepared by spark plasma sintering and hot extrusion. Mater Charact 151:6–14

Jia JB, Liu HL, Yang ZG, Peng WJ, Xu Y, Yang Y, Luo JT (2020) Microstructure, densification and mechanical properties of Ti-22Al-25Nb alloy fabricated by spark plasma sintering. J Mater Eng Perform 29(2):1101–1112

Kelly A, Tyson WR (1965) Tensile properties of fibre-reinforced metals: copper/tungsten and copper/molybdenum. J Mech Phys Solids 13(6):329–350

Koo MY, Park JS, Park MK, Kim KT, Hong SH (2012) Effect of aspect ratios of in situ formed TiB whiskers on the mechanical properties of TiBw/Ti-6Al-4V composites. Scripta Mater 66(7):487–490

Li Q, Chen Y, Huang XY, Wang YR, Zhao YK, Ramamurty U, Gao YM (2022) Long-whisker type TiB phase introduced by micron-sized precursors and its prominent strengthening effect in titanium matrix composites. Mater Sci Eng A 841(143021):1–6

Mao Y, Hagiwara M, Emura S (2007) Creep behavior and tensile properties of Mo- and Fe-added orthorhombic Ti-22Al-11Nb-2Mo-1Fe alloy. Scripta Mater 57(3):261–264

Morsi K, Patel VV (2007) Processing and properties of titanium-titanium boride (TiBw) matrix composites-a review. J Mater Sci 42(6):2037–2047

Namini AS, Azadbeh M, Asl MS (2017) Effect of TiB2 content on the characteristics of spark plasma sintered Ti-TiBw composites. Adv Powder Technol 28(6):1564–1572

Niu HZ, Chen YF, Zhang DL, Zhang YS, Lu JW, Zhang W, Zhang PX (2016) Fabrication of a powder metallurgy Ti2AlNb-based alloy by spark plasma sintering and associated microstructure optimization. Mater Design 89:823–829

Orru R, Licheri R, Locci AM, Cincotti A, Cao G (2009) Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater Sci Eng R 63(4–6):127–287

Sim KH, Wang GF, Ju JM, Yang JL, Li X (2017) Microstructure and mechanical properties of a Ti-22Al-25Nb alloy fabricated from elemental powders by mechanical alloying and spark plasma sintering. J Alloy Compd 704:425–433

Smith PR, Rosenberger AH, Shepard MJ, Wheeler R (2000) Review A P/M approach for the fabrication of an orthorhombic titanium aluminide for MMC applications. J Mater Sci 35(13):3169–3179

Tang F, Nakazawa S, Hagiwara M (2001) Effect of boron microalloying on microstructure, tensile properties and creep behavior of Ti-22Al-20Nb-2W alloy. Mater Sci Eng A 315(1):147–152

Tjong SC, Ma ZY (2000) Microstructural and mechanical characteristics of in situ metal matrix composites. Mater Sci Eng R 29(3–4):49–113

Tjong SC, Mai YW (2008) Processing-structure-property aspects of particulate- and whisker-reinforced titanium matrix composites. Compos Sci Technol 68(3–4):583–601

Varo T, Canakci A (2015) Effect of the CNT content on microstructure, physical and mechanical properties of cu-based electrical contact materials produced by flake powder metallurgy. Arab J Sci Eng 40(9):2711–2720

Wang YH, Lin JP, He YH, Wang YL, Lin Z, Chen GL (2006) Reaction mechanism in high Nb containing TiAl alloy by elemental powder metallurgy. Trans Nonferrous Met Soc China 16(4):853–857

Wei SL, Huang LJ, Li XT, Jiao Y, Ren W, Geng L (2019) Network-strengthened Ti-6Al-4V/(TiC+TiB) composites: powder metallurgy processing and enhanced tensile properties at elevated temperatures. Metall Mater Trans A 50(8):3629–3645

Wu Y, Wang DJ, Liu ZQ, Liu G (2019) A unified internal state variable material model for Ti2AlNb-alloy and its applications in hot gas forming. Int J Mech Sci 164(105126):1–20

Wu Y, Fan RL, Zhou XJ, Chen MH (2020) Microstructure and hot flow stress at 970 °C of various heat-treated Ti2AlNb sheets. Rare Met 39(6):695–706

Yang SJ, Emura S, Hagiwara M, Nam SW (2003) The role of TiB particulate reinforcement in Ti2AlNb based composite under high cycle fatigue. Scripta Mater 49(9):897–902

Yang SJ, Emura S, Nam SW, Hagiwara M, Jeon HS, Yoon SB (2004) Improvement of creep resistance in TiB particle reinforced Ti2AlNb composite particularly above 700 °C. Mater Lett 58(25):3187–3191

Zhang YR, Cai Q, Liu YC, Ma ZQ, Li C, Li HJ (2018) Evaluation of precipitation hardening in TiC-reinforced Ti2AlNb-based alloys. Int J Min Met Mater 25(4):453–458

Zhang YR, Cai Q, Ma ZQ, Li C, Yu LM, Liu YC (2019) Solution treatment for enhanced hardness in Mo-modified Ti2AlNb-based alloys. J Alloy Compd 805:1184–1190

Zhang NB, Sun DL, Han XL et al (2020) Effect of spark plasma sintering temperatures on microstructure and mechanical properties of in-situ (La2O3+TiB)/Ti2AlNb composites with a tailored three-dimensional network architecture. Mater Sci Eng A 772(138769):1–13

Zhang NB, Han XL, Sun DL, Liu H, Xue W, Ju BY, Wu GH (2021) Crystallographic orientation relationships and interfacial structures between reinforcement and matrix phases in an in situ (Ti, Nb)B/Ti2AlNb composite. Appl Surf Sci 542(148592):1–27

Acknowledgements

The authors would like to acknowledge the financial support from the National Natural Science Foundation of China (No. 51805256), the Fundamental Research Funds for the Central Universities (NO. 56XAC21017) and the Postdoctoral Science Foundation of China (NO. 2020M670792).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, T., Fan, R., Wu, Y. et al. Microstructure, densification and mechanical properties of in situ TiBw/Ti2AlNb composites fabricated by spark plasma sintering. J Mater Sci 58, 8359–8378 (2023). https://doi.org/10.1007/s10853-023-08540-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08540-1