Abstract

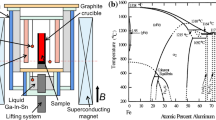

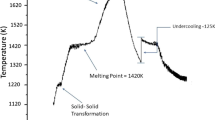

The magnetic and compressive properties of the ternary Ni40.6Fe36.4Ti23 eutectic alloys solidified under electromagnetic levitation condition were investigated. An undercooling range from 32 to 141 K was achieved, and a ternary eutectic consisting of a fibrous Fe2Ti phase and lamellar γ-Fe(Ni) + Ni3Ti phases formed. In the ternary eutectic, the γ-Fe(Ni) and Ni3Ti phases kept cooperative growth, while the Fe2Ti phase grew either cooperatively with these two phases or sometimes independently. Theoretical calculations showed that there existed a vertical flow field and temperature gradient in the center of the levitated alloy droplet, contributing to the directional growth behavior of eutectic grain. The growth velocity of primary Ni3Ti dendrite increased by 2.4 times, while that of ternary eutectic increased by 77% as undercooling rose, and consequently, the microstructures were significantly refined. The temperature stability of coercivity and residual magnetization below ambient temperature was improved once alloy undercooling reached 128 K, ascribed to the enhancement of the exchange coupling effect between the magnetic domains inside refined grains. The fracture strain of the ternary eutectic alloy increased with undercooling because microcrack propagation was further hindered and the plastic deformation was more homogeneous. Meanwhile, the fracture was dominated by transgranular (TG) mode at an undercooling of 132 K because the bonding force of grain boundaries became stronger.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Hecht U, Gránásy L, Pusztai T, Böttger B, Apel M, Witusiewicz V, Ratke L, De Wilde J, Froyen L, Camel D, Drevet B, Faivre G, Fries SG, Legendre B, Rex S (2004) Multiphase solidification in multicomponent alloys. Mater Sci Eng R Rep 46:1–49. https://doi.org/10.1016/j.mser.2004.07.002

Bottin-Rousseau S, Şerefoğlu M, Yücetürk S, Faivre G, Akamatsu S (2016) Stability of three-phase ternary-eutectic growth patterns in thin sample. Acta Mater 109:259–266. https://doi.org/10.1016/j.actamat.2016.01.065

De Wilde J, Froyen L, Witusiewicz VT, Hecht U (2005) Two-phase planar and regular lamellar coupled growth along the univariant eutectic reaction in ternary alloys: An analytical approach and application to the Al–Cu–Ag system. J Appl Phys 97:113515. https://doi.org/10.1063/1.1906286

Benamara O, Cherif M, Duffar T, Lebbou K (2015) Microstructure and crystallography of Al2O3–Y3Al5O12–ZrO2 ternary eutectic oxide grown by the micropulling down technique. J Cryst Growth 429:27–34. https://doi.org/10.1016/j.jcrysgro.2015.07.020

Baker I, Wu M, Wang Z (2019) Eutectic/eutectoid multi-principle component alloys: a review. Mater Charact 147:545–557. https://doi.org/10.1016/j.matchar.2018.07.030

Ruan Y, Wang XJ, Chang SY (2015) Two hardening mechanisms in high-level undercooled Al–Cu–Ge alloys. Acta Mater 91:183–191. https://doi.org/10.1016/j.actamat.2015.03.023

Lewis D, Allen S, Notis M, Scotch A (2002) Determination of the eutectic structure in the Ag-Cu-Sn system. J Electron Mater 31:161–167. https://doi.org/10.1007/s11664-002-0163-y

Genau A, Ratke L (2012) Morphological characterization of the Al–Ag–Cu ternary eutectic. Int J Mater Res 103:469–475. https://doi.org/10.3139/146.110652

Ruggiero MA, Rutter JW (1997) Origin of microstructure in the 332 K eutectic of the Bi-In-Sn system. Mater Sci Technol 13:5–11. https://doi.org/10.1179/mst.1997.13.1.5

Steinmetz P, Dennstedt A, Şerefoğlu M, Sargin I, Genau A, Hecht U (2018) Crystal orientation relationships in ternary eutectic Al-Al2Cu-Ag2Al. Acta Mater 157:96–105. https://doi.org/10.1016/j.actamat.2018.07.016

Hötzer J, Steinmetz P, Jainta M, Schulz S, Kellner M, Nestler B, Genau A, Dennstedt A, Bauer M, Köstler H, Rüde U (2016) Phase-field simulations of spiral growth during directional ternary eutectic solidification. Acta Mater 106:249–259. https://doi.org/10.1016/j.actamat.2015.12.052

Ruan Y, Wang QQ, Chang SY, Wei B (2017) Structural evolution and micromechanical properties of ternary Al-Ag-Ge alloy solidified under microgravity condition. Acta Mater 141:456–465. https://doi.org/10.1016/j.actamat.2017.09.033

Yousefi E, Sharafi S, Irannejad A (2018) The structural, magnetic, and tribological properties of nanocrystalline Fe-Ni permalloy and Fe-Ni-TiO2 composite coatings produced by pulse electro co-deposition. J Alloys Compd 753:308–319. https://doi.org/10.1016/j.jallcom.2018.04.232

Ghorbani M, Iraji zad A, Dolati A, Ghasempour R (2005) The effect of the Cr and Mo on the physical properties of electrodeposited Ni–Fe alloy films. J Alloys Compd 386:43–46. https://doi.org/10.1016/j.jallcom.2004.05.056

Ekholm M, Zapolsky H, Ruban AV, Vernyhora I, Ledue D, Abrikosov IA (2010) Influence of the magnetic state on the chemical order-disorder transition temperature in Fe-Ni permalloy. Phys Rev Lett 105:167208. https://doi.org/10.1103/PhysRevLett.105.167208

An ZG, Zhang JJ, Pan SL (2008) Fabrication of glass/Ni–Fe–P ternary alloy core/shell composite hollow microspheres through a modified electroless plating process. Appl Surf Sci 255:2219–2224. https://doi.org/10.1016/j.apsusc.2008.07.067

Karimi L, Shokrollahi H, Karimi Z, Mohammadi M (2013) Improvement of magnetic properties of nanostructured Ni79Fe16Mo5 alloyed powders by a suitable heat treatment. Adv Powder Technol 24:653–658. https://doi.org/10.1016/j.apt.2012.12.002

Wang JG, Zhao H, Xie CX, Chang CT, Zhou SM, Feng JQ, Huo JT, Li WH (2019) In-situ synthesis of nanocrystalline soft magnetic Fe-Ni-Si-B alloy. J Alloys Compd 790:524–528. https://doi.org/10.1016/j.jallcom.2019.03.226

Al-Joubori AA, Suryanarayana C (2017) Synthesis and stability of the austenite phase in mechanically alloyed Fe–Cr–Ni alloys. Mater Lett 187:140–143. https://doi.org/10.1016/j.matlet.2016.10.084

Rawlings MJS, Liebscher CH, Asta M, Dunand DC (2017) Effect of titanium additions upon microstructure and properties of precipitation-strengthened Fe-Ni-Al-Cr ferritic alloys. Acta Mater 128:103–112. https://doi.org/10.1016/j.actamat.2017.02.028

Aaltio I, Fukuda T, Kakeshita T (2019) Elastocaloric cooling and heating using R-phase transformation in hot rolled Ni-Ti-Fe shape memory alloys with 2 and 4 at% Fe content. J Alloys Compd 780:930–936. https://doi.org/10.1016/j.jallcom.2018.11.406

Matsui I, Kawakatsu T, Takigawa Y, Uesugi T, Higashi K (2014) Fabrication of bulk nanocrystalline Fe–Ni alloys with high strength and high ductility by an electrodeposition. Mater Lett 116:71–74. https://doi.org/10.1016/j.matlet.2013.10.108

Hossein Nedjad S, Meimandi S, Mahmoudi A, Abedi T, Yazdani S, Shirazi H, Nili Ahmadabadi M (2009) Effect of aging on the microstructure and tensile properties of Fe–Ni–Mn–Cr maraging alloys. Mater Sci Eng A 501:182–187. https://doi.org/10.1016/j.msea.2008.09.062

Li XW, Ruan Y, Wei B (2020) Structural evolution and micromechanical properties of ternary Ni-Fe-Ti alloy solidified under microgravity condition. Metall Mater Trans A 51:3461–3472. https://doi.org/10.1007/s11661-020-05792-3

Raghavan V (2011) Fe-Ni-Ti (Iron-Nickel-Titanium). J Phase Equilib Diff 32:377–378. https://doi.org/10.1007/s11669-011-9893-y

Sugiura T, Ishikawa S, Matsuo T, Takeyama M (2007) Phase equilibria between γ-Fe (A1) and Fe2Ti Laves (C14) phases and microstructure in Fe-Ti-Ni ternary system at elevated temperatures. Mater Sci Forum 561–565:435–438. https://doi.org/10.4028/www.scientific.net/MSF.561-565.435

Duarte LI, Klotz UE, Leinenbach C, Palm M, Stein F, Löffler JF (2010) Experimental study of the Fe–Ni–Ti system. Intermetallics 18:374–384. https://doi.org/10.1016/j.intermet.2009.08.008

Park SY, Kim WJ (2017) Enhanced hot workability and post-hot deformation microstructure of the As-cast Al-Zn-Cu-Mg alloy fabricated by use of a high-frequency electromagnetic casting with electromagnetic stirring. Metall Mater Trans A 48:3523–3539. https://doi.org/10.1007/s11661-017-4106-x

Bochtler B, Gross O, Gallino I, Busch R (2016) Thermo-physical characterization of the Fe67Mo6Ni3.5Cr3.5P12C5.5B2.5 bulk metallic glass forming alloy. Acta Mater 118:129–139. https://doi.org/10.1016/j.actamat.2016.07.031

Rodriguez JE, Kreischer C, Volkmann T, Matson DM (2017) Solidification velocity of undercooled Fe–Co alloys. Acta Mater 122:431–437. https://doi.org/10.1016/j.actamat.2016.09.047

Wu YH, Chang J, Wang WL, Hu L, Yang SJ, Wei B (2017) A triple comparative study of primary dendrite growth and peritectic solidification mechanism for undercooled liquid Fe59Ti41 alloy. Acta Mater 129:366–377. https://doi.org/10.1016/j.actamat.2017.03.019

Fe-Ni-Ti Ternary Phase Diagram Evaluation (2014) https://materials.springer.com/msi/docs/sm_msi_r_10_010608_01. Accessed 23 Mar 2020

McCartney DG, Hunt JD, Jordan RM (1980) The structures expected in a simple ternary eutectic system: part 1. Theory Metall Trans A 11:1243–1249. https://doi.org/10.1007/BF02653477

Speich GR (1963) Cellular precipitation in an austenitic Fe-30Ni-6Ti alloy. Trans Met Soc AIME 218:754–762

Fournelle RA (1979) Discontinuous coarsening of lamellar cellular precipitate in an austenitic Fe-30 wt%Ni-6wt.%Ti alloy—I. Morphology Acta Metall 27:1135–1145. https://doi.org/10.1016/0001-6160(79)90131-7

Smithells CJ (1984) Metals reference book. Butterworth, London. Chap. 14, pp 1–14 and Chap. 19, pp 1–16

Cai X, Wang HP, Wei B (2020) Migration dynamics for liquid/solid interface during levitation melting of metallic materials. Int J Heat Mass Transf 151:119386. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119386

Li BQ (1994) The fluid flow aspects of electromagnetic levitation processes. Int J Eng Sci 32:45–67. https://doi.org/10.1016/0020-7225(94)90148-1

Acharya SS, Medicherla VRR, Bapna K, Ali K, Biswas D, Rawat R, Maiti K (2021) Mixed ground state in Fe-Ni Invar alloys. J Alloys Compd 863:158605. https://doi.org/10.1016/j.jallcom.2021.158605

Brown PJ, Deportes J, Ouladdiaf B (1992) Magnetic structure of the Laves phase compound TiFe2. J Phys Condens Mat 4(1992):10015–10024. https://doi.org/10.1088/0953-8984/4/49/028

Herzer G (1990) Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans Magn 26:1397–1402. https://doi.org/10.1109/20.104389

Xue D, Chai G, Li X, Fan X (2008) Effects of grain size distribution on coercivity and permeability of ferromagnets. J Magn Magn Mater 320:1541–1543. https://doi.org/10.1016/j.jmmm.2008.01.004

Zuo J, Hou L, Shi J, Cui H, Zhuang L, Zhang J (2017) The mechanism of grain refinement and plasticity enhancement by an improved thermomechanical treatment of 7055 Al alloy. Mater Sci Eng A 702:42–52. https://doi.org/10.1016/j.msea.2017.06.106

Sorbello F, Flewitt PEJ, Smith G, Crocker AG (2009) The role of deformation twins in brittle crack propagation in iron–silicon steel. Acta Mater 57:2646–2656. https://doi.org/10.1016/j.actamat.2009.02.011

Bond DM, Zikry MA (2017) Differentiating between intergranular and transgranular fracture in polycrystalline aggregates. J Mater Sci 53:5786–5798. https://doi.org/10.1007/s10853-017-1847-2

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. U1806219, 52073232, and 52088101), the Science Fund for Distinguished Young Scholars of Shaanxi Province (Grant No. 2020JC-11), and the Science Fund for Scientific and Technological Innovation Team of Shaanxi Province (Grant No. 2021TD-14). The authors are very grateful to Mr. L.Y. Li for his help with the experiments. They also thank Dr. J. Chang, Mr. S.S. Xu, and Miss. S. Sha for their supports and valuable discussion.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, X.W., Wu, B.W., Ruan, Y. et al. Magnetic and compressive properties of ternary Ni–Fe–Ti eutectic alloy processed by electromagnetic levitation technique. J Mater Sci 56, 15407–15422 (2021). https://doi.org/10.1007/s10853-021-06258-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06258-6