Abstract

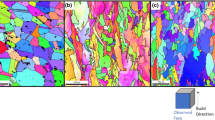

Ti-6Al-4 V is a popular alloy in additive manufacturing (AM) due to its applications in the biomedical implants and aerospace industries where the complex part geometries allowed by AM provide cost and performance benefits. Ti-6Al-4 V goes through a β → α’ transformation after solidification which is known to experience variant selection, e.g., through the formation of clusters of variants which, when situated together, partially accommodate the strain of the phase transformation. During electron beam powder bed fusion AM, an in situ decomposition of α’ martensite occurs during the cyclic reheating caused by melting successive layers, resulting in α + β microstructures. How variant selection influences the evolution beyond the initial rapid cooling remains an open question. Using 3D electron backscatter diffraction, we provide a clearer understanding without ambiguity from sectioning effects of how α’ decomposes into microstructures with distinct morphologies and variant/intervariant distributions. We extract quantitative 3D information on the various intervariant boundaries networks formed in samples printed using three different electron beam scanning strategies. This shows that differing mechanisms during the decomposition result in a shift from self-accommodating clusters in an acicular microstructure, to either the preferred growth of six variants in a basketweave microstructure, or to a colony microstructure where variant selection is determined by prior-β grain boundaries. We propose a new representation of the misorientations arising from the Burgers orientation relationship, which we refer to as intervariant network diagram, to reveal how variant selection during the martensitic transformation and subsequent decomposition leads to the intervariant boundary networks observed. This holistic understanding of the microstructural evolution has the potential to allow tailoring of microstructures and properties for specific applications.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- AM:

-

Additive manufacturing

- E-PBF:

-

Electron-beam powder bed fusion

- BOR:

-

Burgers orientation relationship

- FIB:

-

Focused ion beam

- EBSD:

-

Electron backscatter diffraction

- RHAGB:

-

Random high-angle grain boundary

- IPF:

-

Inverse pole figure

- DVS:

-

Degree of variant selection

References

Collings, E.W. (1984) The physical metallury of titanium alloys, American Society for Metals

Liu S, Shin YC (2019) Additive manufacturing of Ti6Al4V alloy: a review. Mater Des. https://doi.org/10.1016/j.matdes.2018.107552

Gong, X., Anderson, T., Chou, K., (2012) Review on powder-based electron beam additive manufacturing technology, In: ASME/ISCIE 2012 Int. Symp. Flex. Autom., ASME, p. 507 https://doi.org/10.1115/ISFA2012-7256.

Zhang L-C, Liu Y, Li S, Hao Y (2018) Additive manufacturing of titanium alloys by electron beam melting: a review. Adv Eng Mater 20:1700842. https://doi.org/10.1002/adem.201700842

Ahmed T, Rack HJ (1998) Phase transformations during cooling in α + β titanium alloys. Mater Sci Eng A 243:206–211. https://doi.org/10.1016/s0921-5093(97)00802-2

Semiatin SL (2020) An overview of the thermomechanical processing of α/β titanium alloys: current status and future research opportunities. Metall Mater Trans A Phys Metall Mater Sci 51:2593–2625. https://doi.org/10.1007/s11661-020-05625-3

Al-Bermani SS, Blackmore ML, Zhang W, Todd I (2010) The 0rigin of Microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall Mater Trans A 41:3422–3434. https://doi.org/10.1007/s11661-010-0397-x

Tan X, Kok Y, Tan YJ, Descoins M, Mangelinck D, Tor SB, Leong KF, Chua CK (2015) Graded microstructure and mechanical properties of additive manufactured Ti–6Al–4V via electron beam melting. Acta Mater 97:1–16. https://doi.org/10.1016/J.ACTAMAT.2015.06.036

Tan X, Kok Y, Toh WQ, Tan YJ, Descoins M, Mangelinck D, Tor SB, Leong KF, Chua CK (2016) Revealing martensitic transformation and α/β interface evolution in electron beam melting three-dimensional-printed Ti-6Al-4V. Sci Rep 6:1–10. https://doi.org/10.1038/srep26039

Galarraga H, Lados DA, Dehoff RR, Kirka MM, Nandwana P (2016) Effects of the microstructure and porosity on properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Addit Manuf 10:47–57. https://doi.org/10.1016/J.ADDMA.2016.02.003

Galarraga H, Warren RJ, Lados DA, Dehoff RR, Kirka MM, Nandwana P (2017) Effects of heat treatments on microstructure and properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Mater Sci Eng A 685:417–428. https://doi.org/10.1016/J.MSEA.2017.01.019

Rafi HK, Karthik NV, Gong H, Starr TL, Stucker BE (2013) Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J Mater Eng Perform 22:3872–3883. https://doi.org/10.1007/s11665-013-0658-0

Murr LE, Esquivel EV, Quinones SA, Gaytan SM, Lopez MI, Martinez EY, Medina F, Hernandez DH, Martinez E, Martinez JL, Stafford SW, Brown DK, Hoppe T, Meyers W, Lindhe U, Wicker RB (2009) Microstructures and mechanical properties of electron beam-rapid manufactured Ti–6Al–4V biomedical prototypes compared to wrought Ti–6Al–4V. Mater Charact 60:96–105. https://doi.org/10.1016/J.MATCHAR.2008.07.006

Antonysamy AA, Meyer J, Prangnell PB (2013) Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti6Al4V by selective electron beam melting. Mater Charact 84:153–168. https://doi.org/10.1016/j.matchar.2013.07.012

Sridharan N, Chen Y, Nandwana P, Ulfig RM, Larson DJ, Babu SS (2019) On the potential mechanisms of b to a’+ b decomposition in two phase titanium alloys during additive manufacturing: a combined transmission Kikuchi diffraction and 3D atom probe study. J Mater Sci. https://doi.org/10.1007/s10853-019-03984-w

Wu MW, Chen JK, Lin BH, Chiang PH, Tsai MK (2020) Compressive fatigue properties of additive-manufactured Ti-6Al-4V cellular material with different porosities. Mater Sci Eng A. https://doi.org/10.1016/j.msea.2020.139695

Barriobero-Vila P, Artzt K, Stark A, Schell N, Siggel M, Gussone J, Kleinert J, Kitsche W, Requena G, Haubrich J (2020) Mapping the geometry of Ti-6Al-4V: from martensite decomposition to localized spheroidization during selective laser melting. Scr Mater 182:48–52. https://doi.org/10.1016/j.scriptamat.2020.02.043

Xu W, Brandt M, Sun S, Elambasseril J, Liu Q, Latham K, Xia K, Qian M (2015) Additive manufacturing of strong and ductile Ti-6Al-4V by selective laser melting via in situ martensite decomposition. Acta Mater 85:74–84. https://doi.org/10.1016/j.actamat.2014.11.028

Xu W, Lui EW, Pateras A, Qian M, Brandt M (2017) In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater 125:390–400. https://doi.org/10.1016/j.actamat.2016.12.027

Fan H, Yang S (2020) Effects of direct aging on near-alpha Ti–6Al–2Sn–4Zr–2Mo (Ti-6242) titanium alloy fabricated by selective laser melting (SLM). Mater Sci Eng A. https://doi.org/10.1016/j.msea.2020.139533

Zhang D, Wang L, Zhang H, Maldar A, Zhu G, Chen W, Park JS, Wang J, Zeng X (2020) Effect of heat treatment on the tensile behavior of selective laser melted Ti-6Al-4V by in situ X-ray characterization. Acta Mater 189:93–104. https://doi.org/10.1016/j.actamat.2020.03.003

Burgers WG (1934) On the process of transition of the cubic-body-centered modification into the hexagonal-close-packed modification of zirconium. Physica 1:561–586. https://doi.org/10.1016/S0031-8914(34)80244-3

Gey N, Humbert M (2002) Characterization of the variant selection occurring during the α→β→α phase transformations of a cold rolled titanium sheet. Acta Mater 50:277–287. https://doi.org/10.1016/S1359-6454(01)00351-2

Gey N, Humbert M, Philippe MJ, Combres Y (1996) Investigation of the α- and β- texture evolution of hot rolled Ti-64 products. Mater Sci Eng A 219:80–88. https://doi.org/10.1016/S0921-5093(96)10388-9

Hémery S, Naït-Ali A, Guéguen M, Wendorf J, Polonsky AT, Echlin MP, Stinville JC, Pollock TM, Villechaise P (2019) A 3D analysis of the onset of slip activity in relation to the degree of micro-texture in Ti-6Al-4V. Acta Mater. https://doi.org/10.1016/j.actamat.2019.09.028

Qiu D, Shi R, Zhang D, Lu W, Wang Y (2015) Variant selection by dislocations during α precipitation in α/β titanium alloys. Acta Mater 88:218–231. https://doi.org/10.1016/j.actamat.2014.12.044

Bhattacharyya D, Viswanathan G, Denkenberger R, Furrer D, Fraser HL (2003) The role of crystallographic and geometrical relationships between α and β phases in an α/β titanium alloy. Acta Mater 51:4679–4691. https://doi.org/10.1016/S1359-6454(03)00179-4

Lee E, Banerjee R, Kar S, Bhattacharyya D, Fraser HL (2007) Selection of α variants during microstructural evolution in α/β titanium alloys. Philos Mag 87:3615–3627. https://doi.org/10.1080/14786430701373672

Bhattacharyya D, Viswanathan GB, Fraser HL (2007) Crystallographic and morphological relationships between β phase and the Widmanstätten and allotriomorphic α phase at special β grain boundaries in an α/β titanium alloy. Acta Mater 55:6765–6778. https://doi.org/10.1016/j.actamat.2007.08.029

Banerjee R, Bhattacharyya D, Collins PC, Viswanathan GB, Fraser HL (2004) Precipitation of grain boundary α in a laser deposited compositionally graded Ti-8Al-xV alloy—An orientation microscopy study. Acta Mater 52:377–385. https://doi.org/10.1016/j.actamat.2003.09.038

Stanford N, Bate PS (2004) Crystallographic variant selection in Ti-6Al-4V. Acta Mater 52:5215–5224. https://doi.org/10.1016/j.actamat.2004.07.034

Shi R, Dixit V, Viswanathan GB, Fraser HL, Wang Y (2016) Experimental assessment of variant selection rules for grain boundary α in titanium alloys. Acta Mater 102:197–211. https://doi.org/10.1016/j.actamat.2015.09.021

Furuhara T, Takagi S, Watanabe H, Mak T (1996) Crystallography of grain boundary α precipitates in a β titanium alloy. Metall Mater Trans A Phys Metall Mater Sci 27:1635–1646. https://doi.org/10.1007/BF02649821

Lee JK, Aaronson HI (1975) Influence of faceting upon the equilibrium shape of nuclei at grain boundaries-II. Three Dimen Acta Metall 23:809–820. https://doi.org/10.1016/0001-6160(75)90197-2

Lee JK, Aaronson H (1975) Influence of faceting upon the equilibrium shape of nuclei at grain boundaries—I. Two-dimensions, Acta Metall 23:799–808. https://doi.org/10.1016/0001-6160(75)90196-0

Wang SC, Aindow M, Starink MJ (2003) Effect of self-accommodation on α/α boundary populations in pure titanium. Acta Mater 51:2485–2503. https://doi.org/10.1016/S1359-6454(03)00035-1

Farabi E, Hodgson PD, Rohrer GS, Beladi H (2018) Five-parameter intervariant boundary characterization of martensite in commercially pure titanium. Acta Mater 154:147–160. https://doi.org/10.1016/j.actamat.2018.05.023

Miyano N, Norimura T, Inaba T, Ameyama K (2006) Reasons for Formation of triangular α precipitates in Ti–15V–3Cr–3Sn–3Al β titanium alloy. Mater Trans 47:341–347. https://doi.org/10.2320/matertrans.47.341

Balachandran S, Kashiwar A, Choudhury A, Banerjee D, Shi R, Wang Y (2016) On variant distribution and coarsening behavior of the α phase in a metastable β titanium alloy. Acta Mater 106:374–387. https://doi.org/10.1016/J.ACTAMAT.2016.01.023

Beladi H, Chao Q, Rohrer GS (2014) Variant selection and intervariant crystallographic planes distribution in martensite in a Ti–6Al–4V alloy. Acta Mater 80:478–489. https://doi.org/10.1016/J.ACTAMAT.2014.06.064

Wei Z, Yang P, Gu X, Onuki Y, Sato S (2020) Transformation textures in pure titanium: Texture memory vs surface effect. Mater Charact. https://doi.org/10.1016/j.matchar.2020.110359

Farabi E, Tari V, Hodgson PD, Rohrer GS, Beladi H (2020) On the grain boundary network characteristics in a martensitic Ti-6Al-4V alloy. J Mater Sci. https://doi.org/10.1007/s10853-020-05075-7

Simonelli M, Tse YY, Tuck C (2014) On the texture formation of selective laser melted Ti-6Al-4V. Metall Mater Trans A Phys Metall Mater Sci 45:2863–2872. https://doi.org/10.1007/s11661-014-2218-0

Liu Q, Qiu C (2020) Variant selection of α precipitation in a beta titanium alloy during selective laser melting and its influence on mechanical properties. Mater Sci Eng A. https://doi.org/10.1016/j.msea.2020.139336

Jiao Z, Fu J, Li Z, Cheng X, Tang H, Wang H (2018) The spatial distribution of α phase in laser melting deposition additive manufactured Ti-10V-2Fe-3Al alloy. Mater Des 154:108–116. https://doi.org/10.1016/j.matdes.2018.05.032

Williams, R.E.A., Uchic, M., Dimiduk, D., Fraser, H.L. (2006) Three dimensional reconstruction of alpha laths in α/β titanium alloys by serial sectioning with a FEI NOVA 600. In: Microsc. Microanal., Cambridge University Press, pp. 1234–1235 https://doi.org/10.1017/S1431927606066256

Searles T, Tiley J, Tanner A, Williams R, Rollins B, Lee E, Kar S, Banerjee R, Fraser HL (2005) Rapid characterization of titanium microstructural features for specific modelling of mechanical properties. Meas Sci Technol 16:60–69. https://doi.org/10.1088/0957-0233/16/1/009

Sharma H, van Bohemen SMC, Petrov RH, Sietsma J (2010) Three-dimensional analysis of microstructures in titanium. Acta Mater 58:2399–2407. https://doi.org/10.1016/j.actamat.2009.12.026

Nandwana P, Nag S, Hill D, Tiley J, Fraser HL, Banerjee R (2012) On the correlation between the morphology of α and its crystallographic orientation relationship with TiB and β in boron-containing Ti-5Al-5Mo-5V-3Cr-0.5Fe alloy. Scr Mater 66:598–601. https://doi.org/10.1016/j.scriptamat.2012.01.011

Barriobero-Vila P, Gussone J, Haubrich J, Sandlöbes S, Da Silva J, Cloetens P, Schell N, Requena G (2017) Inducing stable α + β microstructures during selective laser melting of Ti-6Al-4V using intensified intrinsic heat treatments. Materials (Basel). https://doi.org/10.3390/ma10030268

Williams, R., Bhattacharyya, D., Viswanathan, G.B., Banerjee, R., Fraser, H.L., (2004) Application of FIB-tomography to the study of microstructures in titanium alloys, in: Microsc. Microanal., Cambridge University Press, pp. 1178–1179 https://doi.org/10.1017/S1431927604884186

Williams, R.E.A., Huber, D., Sosa, J., Fraser, H.L. (2014) 15 years of characterizing titanium alloys’ microstructure by DBFIB. In: Microsc. Microanal., Cambridge University Press, pp. 322–323 https://doi.org/10.1017/S143192761400333X

Hull DA, McCammond D, Hoeppner DW, Hellier WG (1991) Titanium prior-beta grain volume distribution by quantitative serial sectioning techniques. Mater Charact 26:63–71. https://doi.org/10.1016/1044-5803(91)90067-E

Vanderesse N, Maire E, Darrieulat M, Montheillet F, Moreaud M, Jeulin D (2008) Three-dimensional microtomographic study of Widmanstätten microstructures in an alpha/beta titanium alloy. Scr Mater 58:512–515. https://doi.org/10.1016/j.scriptamat.2007.11.005

He D, Zaefferer S, Zhu J, Lai Z (2012) Three-dimensional morphological and crystallographic investigation of lamellar alpha and retained beta in a near alpha titanium alloy by combination of focused ion beam and electron backscattering diffraction. Steel Res Int. https://doi.org/10.1002/srin.201200013

Kashiwar, A. (2014) 3D MICROSTRUCTURAL CHARACTERIZATION IN SOME ALLOYS USING SERIAL SECTIONING TECHNIQUES, IISc Bangalore. http://materials.iisc.ernet.in/~dbanerjee/assets/thesis_ankush.pdf. Accessed 2 May 2019

Wielewski E, Menasche DB, Callahan PG, Suter RM (2015) Three-dimensional colony characterization and prior-β grain reconstruction of a lamellar Ti-6Al-4V specimen using near-field high-energy X-ray diffraction microscopy. J Appl Crystallogr 48:1165–1171. https://doi.org/10.1107/S1600576715011139

Tiley JS, Shiveley AR, Pilchak AL, Shade PA, Groeber MA (2014) 3D reconstruction of prior β grains in friction stir-processed Ti-6Al-4V. J Microsc 255:71–77. https://doi.org/10.1111/jmi.12137

Burnett TL, Kelley R, Winiarski B, Contreras L, Daly M, Gholinia A, Burke MG, Withers PJ (2016) Large volume serial section tomography by Xe Plasma FIB dual beam microscopy. Ultramicroscopy. https://doi.org/10.1016/j.ultramic.2015.11.001

DeMott R, Collins P, Kong C, Liao X, Ringer S, Primig S (2020) 3D electron backscatter diffraction study of α lath morphology in additively manufactured Ti-6Al-4V. Ultramicroscopy. https://doi.org/10.1016/j.ultramic.2020.113073

Ma J, Tian J, Yan M, Chen Z, Shen J, Wu J (2020) Defect analysis and 2D/3D-EBSD investigation of an electron beam melted Ti-6Al-4V alloy. Mater Charact. https://doi.org/10.1016/j.matchar.2020.110440

Kirka MM, Lee Y, Greeley DA, Okello A, Goin MJ, Pearce MT, Dehoff RR (2017) Strategy for texture management in metals additive manufacturing. JOM 69:523–531. https://doi.org/10.1007/s11837-017-2264-3

Dehoff, R. R., Kirka, M. M., Sames, W. J., Bilheux, H., Tremsin, A. S., Lowe, L. E., Babu, S. S (2014) Site specific control of crystallographic grain orientation through electron beam additive manufacturing. Mater Sci Technol https://doi.org/10.1179/1743284714Y.0000000734

Evans R, Walker J, Middendorf J, Gockel J (2020) Modeling and monitoring of the effect of scan strategy on microstructure in additive manufacturing. Metall Mater Trans A Phys Metall Mater Sci 51:4123–4129. https://doi.org/10.1007/s11661-020-05830-0

Juechter V, Scharowsky T, Singer RF, Körner C (2014) Processing window and evaporation phenomena for Ti-6Al-4V produced by selective electron beam melting. Acta Mater 76:252–258. https://doi.org/10.1016/j.actamat.2014.05.037

Haghdadi N, DeMott R, Stephenson PL, Liao XZ, Ringer SP, Primig S (2020) Five-parameter characterization of intervariant boundaries in additively manufactured Ti-6Al-4V. Mater Des. https://doi.org/10.1016/j.matdes.2020.109177

Stephenson PL, Haghdadi N, DeMott R, Liao XZ, Ringer SP, Primig S (2020) Effect of scanning strategy on variant selection in additively manufactured Ti-6Al-4V. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101581

Shao M, Vijayan S, Nandwana P, Jinschek JR (2020) The effect of beam scan strategies on microstructural variations in Ti-6Al-4 V fabricated by electron beam powder bed fusion. Mater Des. https://doi.org/10.1016/j.matdes.2020.109165

Groeber MA, Jackson MA (2014) DREAM3D: a digital representation environment for the analysis of microstructure in 3D. Integr Mater Manuf Innov 3:56–72. https://doi.org/10.1186/2193-9772-3-5

Bachmann, F., Hielscher, R., Schaeben, H. (2010) Texture analysis with MTEX- Free and open source software toolbox. In: Solid State Phenom., Trans Tech Publications Ltd, pp. 63–68 https://doi.org/10.4028/www.scientific.net/SSP.160.63.

van Bohemen SMC, Kamp A, Petrov RH, Kestens LAI, Sietsma J (2008) Nucleation and variant selection of secondary α plates in a β Ti alloy. Acta Mater 56:5907–5914. https://doi.org/10.1016/j.actamat.2008.08.016

Quintana, M. J., Kenney, M. J., Agrawal, P., Collin, C. (2020) Texture analysis of additively manufactured Ti-6Al-4V deposited using different scanning strategies. Metall Mater Trans A Phys Metall Mater Sci 51:574–6583 https://doi.org/10.1007/s11661-020-06040-4.

Pesach A, Tiferet E, Vogel SC, Chonin M, Diskin A, Zilberman L, Rivin O, Yeheskel O, Caspi EN (2018) Texture analysis of additively manufactured Ti-6Al-4V using neutron diffraction. Addit Manuf 23:394–401. https://doi.org/10.1016/j.addma.2018.08.010

Reed BW, Adams BL, Bernier JV, Hefferan CM, Henrie A, Li SF, Lind J, Suter RM, Kumar M (2012) Experimental tests of stereological estimates of grain boundary populations. Acta Mater 60:2999–3010. https://doi.org/10.1016/j.actamat.2012.02.005

Song J, Han Y, Fang M, Hu F, Ke L, Li Y, Lei L, Lu W (2020) Temperature sensitivity of mechanical properties and microstructure during moderate temperature deformation of selective laser melted Ti-6Al-4V alloy. Mater Charact. https://doi.org/10.1016/j.matchar.2020.110342

Banerjee D, Williams JC (2013) Perspectives on titanium science and technology. Acta Mater 61:844–879. https://doi.org/10.1016/j.actamat.2012.10.043

Miyazawa K, Iwasaki Y, Ito K, Ishida Y (1996) Combination rule of Σ values at triple junctions in cubic polycrystals. Acta Crystallogr Sect A Found Crystallogr 52:787–796. https://doi.org/10.1107/S0108767396005934

Makiewicz, K. Keller, M., Chaudhary, A. B., Babu, S. S. (2012) Microstructure evolution during laser additive manufacturing of Ti6Al4V Alloys. In: DebRoy, T., David, S. A., DuPont, J. N., Koseki, T., Bhadeshia, H. K. (eds), 9th Int. Conf. Trends Weld., American Society for Metals, 2012. https://www.researchgate.net/publication/267902949_Microstructure_Evolution_During_Laser_Additive_Manufacturing_of_Ti6Al4V_Alloys. Accessed 28 Aug 2020

Galati M, Iuliano L (2018) A literature review of powder-based electron beam melting focusing on numerical simulations. Addit Manuf 19:1–20. https://doi.org/10.1016/j.addma.2017.11.001

Landau E, Tiferet E, Ganor YI, Ganeriwala RK, Matthews MJ, Braun D, Chonin M, Ziskind G (2020) Thermal characterization of the build chamber in electron beam melting. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101535

Acknowledgements

The authors acknowledge funding from the Department of Industry, Innovation and Science under the auspices of the AUSMURI program (AUSMURI000005). The authors further acknowledge the facilities, as well as the scientific and technical support of the Microscopy Australia node at UNSW Sydney (Mark Wainwright Centre). We would also like to thank Prof. Sudarsanam Suresh Babu and Sabina Kumar at The University of Tennessee, Knoxville for providing materials, Prof. Peter Collins and Matthew Kenney at The University of Iowa, Dr. Charlie Kong at UNSW Sydney for fruitful discussions, and Mike Jackson for support with the DREAM.3D software package. S. Primig is further supported by the Australian Research Council DECRA (DE180100440) and UNSW Scientia Fellowship schemes.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest related to this work.

Additional information

Handling Editor: David Cann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 35500 kb)

Supplementary file2 (MP4 37235 kb)

Supplementary file3 (MP4 36943 kb)

Supplementary file4 (MP4 35682 kb)

Supplementary file5 (MP4 39867 kb)

Supplementary file6 (MP4 28221 kb)

Supplementary file7 (MP4 14071 kb)

Supplementary file8 (MP4 14221 kb)

Rights and permissions

About this article

Cite this article

DeMott, R., Haghdadi, N., Liao, X. et al. 3D characterization of microstructural evolution and variant selection in additively manufactured Ti-6Al-4 V. J Mater Sci 56, 14763–14782 (2021). https://doi.org/10.1007/s10853-021-06216-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06216-2