Abstract

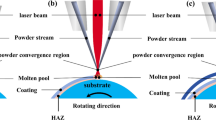

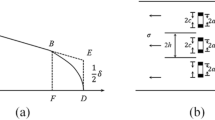

Crack is one of the common problems in preparation of NiCrBSi alloy coatings by laser cladding, especially for high hardness coatings. In this study, the crack behavior and prevention of Ni60A coating by coaxial laser cladding are investigated. The results indicate that the nonuniform hard Cr-rich precipitates and large residual tensile stress are the main reason for cracking of Ni60A coating. According to the difference of thermophysical properties and temperature between the coating and the substrate, the thermal stress models are established, in which the stress perpendicular to the scanning direction \(\sigma_{{\text{y}}}\) is smaller than the stress along the scanning direction \(\sigma_{{\text{x}}}\). Due to the change in the relative relationship among \(\sigma_{{\text{x}}}\), \(\sigma_{{\text{y}}}\) and fracture strength \(\sigma_{{\text{f}}}\), the crack distribution changes from network to parallel, until to no crack with the increasing line energy and the decreasing powder feed rate. And the angle \(\theta_{{0}}\) between the direction of resultant stress of \(\sigma_{{\text{x}}}\) and \(\sigma_{{\text{y}}}\) and Y-axis is 52.85°, which fits with the direction of long and short cracks in network crack distribution. In addition, the substrate preheating can effectively reduce cracking rate of Ni60A coating and completely prevent crack when preheated up to 500 °C. Also, the crack-free coating can be obtained by the combination of preheating to 300 °C and placing insulated plank under the substrate, which can reduce thermal damage of the substrate and obtain higher microhardness.

Similar content being viewed by others

References

Sexton L, Lavin S, Byrne G, Kennedy A (2002) Laser cladding of aerospace materials. J Mater Process Technol 122(1):63–68. https://doi.org/10.1016/S0924-0136(01)01121-9

Paul CP, Jain A, Ganesh P, Negi J, Nath AK (2006) Laser rapid manufacturing of Colmonoy-6 components. Opt Laser Eng 44(10):1096–1109. https://doi.org/10.1016/j.optlaseng.2005.08.005

Weng F, Chen CZ, Yu HJ (2014) Research status of laser cladding on titanium and its alloys: a review. Mater Des 58:412–425. https://doi.org/10.1016/j.matdes.2014.01.077

Fu FX, Zhang YL, Chang GG, Dai J (2016) Analysis on the physical mechanism of laser cladding crack and its influence factors. Optik 127(1):200–202. https://doi.org/10.1016/j.ijleo.2015.10.043

De Oliveira U, Ocelík V, De Hosson JTM (2005) Analysis of coaxial laser cladding processing conditions. Surf Coat Technol 197(2–3):127–136. https://doi.org/10.1016/j.surfcoat.2004.06.029

Zhou SF, Zeng XY, Hu QW, Huang YJ (2008) Analysis of crack behavior for Ni-based WC composite coatings by laser cladding and crack-free realization. Appl Surf Sci 255(5):1646–1653. https://doi.org/10.1016/j.apsusc.2008.04.003

Wang DS, Liang EJ, Chao MJ, Yuan B (2008) Investigation on the microstructure and cracking susceptibility of laser-clad V2O5/NiCrBSiC alloy coatings. Surf Coat Technol 202(8):1371–1378. https://doi.org/10.1016/j.surfcoat.2007.06.036

Huang YJ, Zeng XY (2010) Investigation on cracking behavior of Ni-based coating by laser-induction hybrid cladding. Appl Surf Sci 256(20):5985–5992. https://doi.org/10.1016/j.apsusc.2010.03.106

Hemmati I, Ocelík V, De Hosson JTM (2012) Dilution effects in laser cladding of Ni–Cr–B–Si–C hardfacing alloys. Mater Lett 84:69–72. https://doi.org/10.1016/j.matlet.2012.06.054

Chen ZH, Li RF, Gu JY, Zhang ZY, Tao YW, Tian YT (2020) Laser cladding of Ni60+17-4PH composite for a cracking-free and corrision resistive coating. Int J Mod Phys B 34(1–3):2040042. https://doi.org/10.1142/S0217979220400421

Zhang P, Ma L, Yuan JP, Yin XN, Cai ZH (2008) The finite element simulation research on stress-strain field of laser cladding. Key Eng Mater 373–374:322–325

Brückner F, Lepski D, Beyer E (2007) Modeling the influence of process parameters and additional heat sources on residual stresses in laser cladding. J Therm Spray Technol 16(3):355–373. https://doi.org/10.1007/s11666-007-9026-7

Hemmati I, Ocelík V, De Hosson JTM (2013) Effects of the alloy composition on phase constitution and properties of laser deposited Ni–Cr–B–Si coatings. Phys Proc 41:302–311. https://doi.org/10.1016/j.phpro.2013.03.082

Xu GJ, Kutsuna M, Liu ZJ, Zhang H (2006) Characteristics of Ni-based coating layer formed by laser and plasma cladding processes. Mater Sci Eng A 417(1–2):63–72. https://doi.org/10.1016/j.msea.2005.08.192

Wang HY, Zuo DW, Sun YL, Xu F, Zhang D (2009) Microstructure of nanometer Al2O3 dispersion strengthened Ni-based high-temperature protective coatings by laser cladding. Trans Nonferrous Met Soc China 19(3):586–591. https://doi.org/10.1016/S1003-6326(08)60317-9

Guo C, Chen JM, Zhou JS, Zhao JR, Wang LQ, Yu YJ, Zhou HD (2012) Effects of WC-Ni content on microstructure and wear resistance of laser cladding Ni-based alloys coating. Surf Coat Technol 206(8–9):2064–2071. https://doi.org/10.1016/j.surfcoat.2011.06.005

Wang CL, Gao Y, Wang R, Wei DQ, Cai M, Fu YK (2018) Microstructure of laser-clad Ni60 cladding layers added with different amounts of rare-earth oxides on 6063 Al alloys. J Alloy Compd 740:1099–1107. https://doi.org/10.1016/j.jallcom.2018.01.061

Zhai LL, Wang Q, Zhang JW, Ban CY (2019) Effect of alternating current electric field on microstructure and properties of laser cladding Ni–Cr–B–Si coating. Ceram Int 45(14):16873–16879. https://doi.org/10.1016/j.ceramint.2019.05.230

Ning FD, Cong WL (2020) Ultrasonic vibration-assisted (UV-A) manufacturing processes: state of the art and future perspectives. J Manuf Process 51:174–190. https://doi.org/10.1016/j.jmapro.2020.01.028

Wang FJ, Mao HD, Zhang DW, Zhao XY, Shen Y (2008) Online study of cracks during laser cladding process based on acoustic emission technique and finite element analysis. Appl Surf Sci 255(5):3267–3275. https://doi.org/10.1016/j.apsusc.2008.09.039

Jendrzejewski R, Śliwiński G, Krawczuk M, Ostachowicz W (2004) Temperature and stress fields induced during laser cladding. Comput Struct 82(7–8):653–658. https://doi.org/10.1016/j.compstruc.2003.11.005

Jendrzejewski R, Śliwiński G, Krawczuk M, Ostachowicz W (2006) Temperature and stress during laser cladding of double-layer coatings. Surf Coat Technol 201(6):3328–3334. https://doi.org/10.1016/j.surfcoat.2006.07.065

Zhou SF, Huang YJ, Zeng XY (2008) A study of Ni-based WC composite coatings by laser induction hybrid rapid cladding with elliptical spot. Appl Surf Sci 254(10):3110–3119. https://doi.org/10.1016/j.apsusc.2007.10.062

Irwin GR (1962) Crack-extension force for a part-through crack in a plate. J Appl Mech 29(4):651–654. https://doi.org/10.1115/1.3640649

Hemmati I, Ocelík V, Csach K, de Hosson JTM (2014) Microstructure and phase formation in a rapidly solidified laser-deposited Ni–Cr–B–Si–C hardfacing alloy. Metall Mater Trans A 45(2):878–892. https://doi.org/10.1007/s11661-013-2004-4

Wang DZ, Hu QW, Zeng XY (2015) Residual stress and cracking behaviors of Cr13Ni5Si2 based composite coatings prepared by laser-induction hybrid cladding. Surf Coat Technol 274:51–59. https://doi.org/10.1016/j.surfcoat.2015.04.035

Liyanage T, Fisher G, Gerlich AP (2010) Influence of alloy chemistry on microstructure and properties in NiCrBSi overlay coatings deposited by plasma transferred arc welding (PTAW). Surf Coat Technol 205(3):759–765. https://doi.org/10.1016/j.surfcoat.2010.07.095

Martinez Hurtado A, Francis JA, Stevens NPC (2016) An assessment of residual stress mitigation strategies for laser clad deposits. Mater Sci Technol 32(14):1484–1494. https://doi.org/10.1080/02670836.2016.1192766

Albert Sue J, Schajer GS (1998) Stress determination for coatings. In: Lampman SR, Reidenbach F (eds) Surface engineering. ASM handbook. ASM International Materials Park (OH), Almere

Zhou SF, Zeng XY (2010) Growth characteristics and mechanism of carbides precipitated in WC–Fe composite coatings by laser induction hybrid rapid cladding. J Alloys Compd 505(2):685–691. https://doi.org/10.1016/j.jallcom.2010.06.115

Zhang J, Hu Y, Tan XJ, Guo L, Zhang QM (2015) Microstructure and high temperature tribological behavior of laser cladding Ni60A alloys coatings on 45 steel substrate. Trans Nonferrous Met Soc China 255(5):1525–1532. https://doi.org/10.1016/S1003-6326(15)63754-2

Acknowledgements

This work was jointly supported by the National Natural Science Foundation of China (No.51975099), the Fundamental Research Funds for the Central Universities of China (No. DUT18JC13) and Collaborative Innovation Center of Major Machine Manufacturing in Liaoning Province, China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this article.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shi, B., Li, T., Wang, D. et al. Investigation on crack behavior of Ni60A alloy coating produced by coaxial laser cladding. J Mater Sci 56, 13323–13336 (2021). https://doi.org/10.1007/s10853-021-06108-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06108-5