Abstract

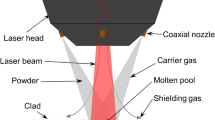

Extreme-high-speed laser cladding (EHLA), as a novel surface treatment technique, has attracted great attention because of its high cladding rate and good performance of cladding coatings. However, when depositing coatings with high cracking susceptibility, such as Ni60 coatings, cracks are difficult to avoid. Therefore, an extreme-high-speed laser-induction hybrid cladding technology (EH-LIHC) was innovatively proposed in this study. The effects of different preheating temperatures on the surface morphology, internal defects, microstructure, and mechanical properties of Ni60 coatings that were deposited by EHLA and EH-LIHC were analyzed. The results show that the roughness of the coating deposited by EHLA is 26.228 μm. However, the surface roughness of the coating deposited by EH-LIHC at 400 ℃ decreases to 14.316 μm. Simultaneously, the pores- and cracks-free Ni60 coating was deposited at 400 ℃. The coating dilution rate obviously increases as the preheating temperature rises. When the preheating temperature rises, the size of the grains and precipitates also increases. However, although Fe elemental diffusion is increased, there is no significant effect on the properties of the coating. The hardness of the coating fluctuates between 700 and 900 HV, nearly three times that of the substrate. As the preheating temperature rises, the coating’s wear mechanism shifts from abrasive to abrasive and adhesive wear, and eventually back to abrasive wear. The improvement of wear resistance of the Ni60 coating deposited at 400 ℃ was mainly attributed to its high hardness and uniform and dense microstructure. The proposed EH-LIHC technique provides a promising method for the efficient deposit of crack-free coatings with good properties.

Similar content being viewed by others

Data availability

All research data supporting this publication are directly available within this publication.

References

F.F. Khan, G. Bae, K. Kang, S. Kumar, T. Jeong, C. Lee, Surf. Coatings Technol. 204, 345 (2009)

S.M. Gateman, S.A. Alidokht, E. Mena-Morcillo, R. Schulz, R.R. Chromik, A.M. Kietzig, I.P. Parkin, J. Mauzeroll, Surf. Coatings Technol. 426, 127790 (2021)

D. Fu, T.A. Kurniawan, R. Avtar, P. Xu, M.H.D. Othman, Chemosphere 271, 129861 (2021)

S. Sitthipong, P. Towatana, A. Sitticharoenchai, C. Meengam, Mater. Today Proc. 4, 1492 (2017)

X. Qiao, Y.M. Wang, W.X. Weng, B.L. Liu, Q. Li, Ceram. Int. 44, 21564 (2018)

W. Shang, F. Wu, S. Jiang, Y. Wen, N. Peng, J. Jiang, J. Mol. Liq. 330, 115606 (2021)

T. Yamaguchi, K. Tanaka, H. Hagino, Int. J. Refract. Met. Hard Mater. 110, 106020 (2023)

B. Wen, J. Zhou, P. Tang, X. Jia, W. Zhou, J. Huang, J. Hazard. Mater. 446, 130622 (2022)

Q. Zhang, Q. Wang, B. Han, M. Li, C. Hu, J. Wang, J. Alloys Compd. 947, 169517 (2023)

K. Wang, D. Du, G. Liu, Z. Pu, B. Chang, J. Ju, Opt. Laser Technol. (2021). https://doi.org/10.1016/j.optlastec.2020.106504

A. Meghwal, S. Pinches, A. Anupam, L. Lie, P. Munroe, C.C. Berndt, A. Siao Ming Ang, Intermetallics 152, 107769 (2023)

W. Yuan, R. Li, Z. Chen, J. Gu, Y. Tian, Surf. Coatings Technol. 405, 126582 (2021)

J. Zhu, H. Xie, Z. Hu, P. Chen, Q. Zhang, Surf. Coatings Technol. 206, 1396 (2011)

S. Zhou, T. Zhang, Z. Xiong, X. Dai, C. Wu, Z. Shao, Opt. Laser Technol. 59, 131 (2014)

S. Zhou, X. Zeng, Q. Hu, Y. Huang, Appl. Surf. Sci. 255, 1646 (2008)

S. Zhou, Y. Huang, X. Zeng, Q. Hu, Mater. Sci. Eng. A 480, 564 (2008)

S. Zhou, X. Dai, Appl. Surf. Sci. 256, 4708 (2010)

S. Zhou, X. Dai, X. Zeng, Appl. Surf. Sci. 255, 8494 (2009)

L. Meng, P. Sheng, X. Zeng, J. Mater. Res. Technol. 16, 1732 (2022)

L. Meng, B. Zhu, X. Liu, X. Zeng, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 54, 3118 (2023)

Q. Wang, F.Q. Chen, Q. Li, L. Zhang, H. Jin, J.W. Zhang, Mater. Chem. Phys. 291, 126678 (2022)

C. Du, L. Hu, X. Ren, Y. Li, F. Zhang, P. Liu, Y. Li, Surf. Coatings Technol. 424, 127617 (2021)

P. Farahmand, R. Kovacevic, J. Mater. Process. Technol. 222, 244 (2015)

B. Shi, T. Li, Z. Guo, X. Zhang, H. Zhang, Opt. Laser Technol. 149, 107805 (2022)

D.Z. Wang, Q.W. Hu, X.Y. Zeng, Surf. Coatings Technol. 274, 51 (2015)

K. Zhang, S. Wang, W. Liu, R. Long, Appl. Surf. Sci. 317, 839 (2014)

D. Gu, Y.C. Hagedorn, W. Meiners, G. Meng, R.J.S. Batista, K. Wissenbach, R. Poprawe, Acta Mater. 60, 3849 (2012)

P. Gu, T. Qi, L. Chen, T. Ge, X. Ren, Int. J. Refract. Met. Hard Mater. 105, 105834 (2022)

D. Gu, Y. Shen, Mater. Des. 30, 2903 (2009)

Y. Sun, L. Chen, L. Li, X. Ren, Opt. Laser Technol. 132, 106509 (2020)

C.L.A. Leung, S. Marussi, R.C. Atwood, M. Towrie, P.J. Withers, P.D. Lee, Nat. Commun. 9, 1 (2018)

P. Zhang, X. Zhou, X. Cheng, H. Sun, H. Ma, Y. Li, Addit. Manuf. 32, 101026 (2020)

L. Zhou, J. Sun, J. Chen, W. Chen, Y. Ren, Y. Niu, C. Li, W. Qiu, J. Alloys Compd. 928, 167130 (2022)

R. Li, Y. Shi, Z. Wang, L. Wang, J. Liu, W. Jiang, Appl. Surf. Sci. 256, 4350 (2010)

X.B. Zhou, J.T.M. De Hosson, Acta Mater. 44, 421 (1996)

H. Yue, N. Lv, C. Guo, L. Zhao, Q. Li, J. Zhang, Y. Zhang, Opt. Laser Technol. 158, 108802 (2023)

N. Aeronautics, 73, 491 (1980).

H. Ali, L. Ma, H. Ghadbeigi, K. Mumtaz, Mater. Sci. Eng. A 695, 211 (2017)

W. Li, J. Liu, Y. Zhou, S. Wen, Q. Wei, C. Yan, Y. Shi, Scr. Mater. 118, 13 (2016)

Z. Chong, Y. Sun, W. Cheng, C. Han, L. Huang, C. Su, L. Jiang, Mater. Today Commun. 33, 104417 (2022)

Z. Chao, K. Dejun, Diam. Relat. Mater. 133, 109762 (2023)

A. Kiran, M. Koukolíková, J. Vavřík, M. Urbánek, J. Džugan, Materials (Basel) 14, 5129 (2021)

Y. Huang, Opt. Laser Technol. 43, 965 (2011)

L. Meng, B. Zhu, R. Yan, X. Zeng, Q. Hu, D. Wang, J. Mater. Res. Technol. 13, 1431 (2021)

Q. Chen, Y. Zhao, S. Strayer, Y. Zhao, K. Aoyagi, Y. Koizumi, A. Chiba, W. Xiong, A.C. To, Addit. Manuf. 37, 101642 (2021)

H.H. Wang, H.J. Li, X.H. Shi, X.S. Liu, J.A. Kong, H. Zhou, Ceram. Int. 46, 19537 (2020)

W. Wu, S. Ye, R. Wang, C. Zhang, Y. Zhang, X. Lu, J. Mater. Res. Technol. 23, 1609 (2023)

Y.T. Dong, B. Yan, Q.L. Deng, Mater. Guid. 24, 10 (2010)

J. Yang, B. Bai, H. Ke, Z. Cui, Z. Liu, Z. Zhou, H. Xu, J. Xiao, Q. Liu, H. Li, Opt. Laser Technol. 144, 107431 (2021)

C. Nagarjuna, A. Sharma, K. Lee, S.J. Hong, B. Ahn, J. Mater. Res. Technol. 22, 1708 (2023)

D.S. Shim, G.Y. Baek, E.M. Lee, Mater. Sci. Eng. A 682, 550 (2017)

Y. Zhao, T. Yu, C. Guan, J. Sun, X. Tan, Ceram. Int. 45, 20824 (2019)

Y. Li, K. Wang, H. Fu, X. Guo, J. Lin, Appl. Surf. Sci. 585, 152703 (2022)

Z. Bergant, J. Grum, J. Therm. Spray Technol. 18, 380 (2009)

M. Zhang, D. Wang, L. He, X. Ye, W. Ouyang, Z. Xu, W. Zhang, X. Zhou, Opt. Laser Technol. 149, 107845 (2022)

G. Hu, H. Meng, J. Liu, Appl. Surf. Sci. 308, 363 (2014)

S. Zhang, J. Zhou, B. Guo, H. Zhou, Y. Pu, J. Chen, Mater. Sci. Eng. A 491, 47 (2008)

B. Bhushan, Chapter 5 friction, in Introduction to tribology. ed. by T. Ren (Wiley, New York, 2013)

H.N. Xuan, L.Y. Chen, N. Li, H. Wang, C. Zhao, M. Bobrov, S. Lu, L.C. Zhang, Mater. Chem. Phys. 292, 126773 (2022)

Y. Cai Zhao, Y. He, J. Zhang, C. Meng, X. Zhang, S. Zhang, Surf. Coatings Technol. 452, 129049 (2023)

X.P. Tao, S. Zhang, C.H. Zhang, C.L. Wu, J. Chen, A.O. Abdullah, Surf. Coatings Technol. 342, 76 (2018)

G. Hu, H. Meng, J. Liu, Appl. Surf. Sci. 317, 378 (2014)

J.M. Guilemany, C.R.C. Lima, N. Cinca, J.R. Miguel, Surf. Coatings Technol. 201, 2072 (2006)

D. Kesavan, M. Kamaraj, Surf. Coatings Technol. 204, 4034 (2010)

Acknowledgements

The authors are grateful to the projects supported by the Youth Science Foundation of Jiangsu Province (Grant No. BK20210754), the Natural Science Foundation for Post-doctoral Scientists of China (Grant No. 2021M101519), the Natural Science Foundation of China (Grant No. U21A20138, 51975261).

Author information

Authors and Affiliations

Contributions

SL: conceptualization, investigation, writing—original draft. LC: microstructural observations, methodology, reviewing and editing. LZ: methodology. XZ: methodology. XR: conceptualization, supervision, writing—reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, S., Chen, L., Zhu, L. et al. Comparative research on the microstructure and mechanical properties of traditional and induction heating aided extreme-high-speed laser cladding of Ni60 coatings. Appl. Phys. A 130, 159 (2024). https://doi.org/10.1007/s00339-024-07299-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07299-9