Abstract

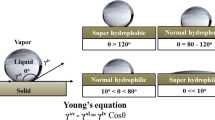

The surface reforming method of metal superhydrophobic surface usually utilizes organic matter, which has the problems of serious environmental pollution, high thermal resistance, low processing efficiency, as well as easy to fall off. According to the application requirements of steam condensation heat transfer on copper surface, a laser micro-/nano-texturing technology assisted by green post-processing method is proposed in this study. In this technology, a nano-second laser was used to texture the surface of pure copper, which will undergo heat treatment to prepare a superhydrophobic surface with micro-/nano-level structures. Scanning electron microscopy and X-ray photoelectron spectroscopy were used to analyze the microstructure changes. A contact angle tester was used to measure the wettability of the surfaces and surface Gibbs energy. Furthermore, steam condensation system was set up to assess surface heat transfer performance. The results show that the laser micro-/nano-textured copper surface has a superhydrophilic contact angle of 4°; after heat treatment, it reaches 161° and became a superhydrophobic surface. As the heat treatment promotes fully oxidation of the textured copper surface, the surface energy is greatly reduced. Due to the formation of nanoscale CuO “clusters” transferred from laser-textured Cu2O by heat treatment, the superhydrophobic surface blocks the growth of condensate droplets and increases the condensation heat transfer coefficient by 4 times to 730.4 W m−2 K−1. It provides a green non-chemical treatment method for heat transfer applications of copper alloy components in the fields of energy, chemical engineering, refrigeration, microelectronics, and batteries.

Similar content being viewed by others

References

Krishnan DV, Kumar GU, Suresh S, Jubal M, Thansekhar MR, Ramesh R (2019) Wetting transition in laser-fabricated hierarchical surface structures and its impact on condensation heat transfer characteristics. Int J Heat Mass Tran 140:886–896

Ji XB, Zhou DD, Dai C, Xu JL (2019) Composite structured surfaces for durable dropwise condensation. Int J Heat Mass Tran 132:52–67

Marieke A, Alexander B, Hans-Jörg B (2019) Is dropwise condensation feasible? a review on surface modifications for continuous dropwise condensation and a profitability analysis. J Adv Res 16:1–13

Darband GB, Aliofkhazraei M, Khorsand S, Sokhanvar S, Kaboli A (2020) Science and engineering of superhydrophobic surfaces: review of corrosion resistance, chemical and mechanical stability. Arab J Chem 13(1):1763–1802

Ellinas K, Tserepi A, Gogolides E (2017) Durable superhydrophobic and superamphiphobic polymeric surfaces and their applications: a review. Adv Colloid Interfac 250:132–157

Orejon D, Askounis A, Takata Y, Attinger D (2019) Dropwise condensation on multiscale bioinspired metallic surfaces with nanofeatures. Acs Appl Mater Inter 11(27):24735–24750

Thickett SC, Neto C, Harris AT (2011) Biomimetic surface coatings for atmospheric water capture prepared by dewetting of polymer films. Adv Mater 23(32):3718. https://doi.org/10.1002/adma.201100290

Tam J, Palumbo G, Erb U (2016) Recent advances in superhydrophobic electrodeposits. Materials 9(3):151. https://doi.org/10.3390/ma9030151

Kietzig AM, Hatzikiriakos SG, Englezos P (2009) Patterned superhydrophobic metallic surfaces. Langmuir 25(8):4821–4827

Schutzius TM, Bayer IS, Jursich GM, Das A, Megaridis CM (2012) Superhydrophobic-superhydrophilic binary micropatterns by localized thermal treatment of polyhedral oligomeric silsesquioxane (POSS)-silica films. Nanoscale 4(17):5378–5385

Preston DJ, Mafra DL, Miljkovic N, Kong J, Wang EN (2015) Scalable graphene coatings for enhanced condensation heat transfer. Nano Lett 15(5):2902–2909

Paxson AT, Yagüe JL, Gleason KK, Varanasi KK (2014) Stable dropwise condensation for enhancing heat transfer via the initiated chemical vapor deposition (iCVD) of grafted polymer films. Adv Mater 26(3):418–423

Helmer D, Keller N, Kotz F, Stolz F, Greiner C, Nargang TM, Sachsenheimer K, Rapp BE (2017) Transparent, abrasion-insensitive superhydrophobic coatings for real-world applications. Sci Rep 7:15078. https://doi.org/10.1038/s41598-017-15287-8

Sharma CS, Stamatopoulos C, Suter R, von Rohr PR, Poulikakos D (2018) Rationally 3D-textured copper surfaces for laplace pressure imbalance-induced enhancement in dropwise condensation. ACS Appl Mater Inter 10(34):29127–29135

Sablowski J, Unz S, Beckmann M (2017) Dropwise condensation on advanced functional surfaces-theory and experimental setup. Chem Eng Technol 40(11):1966–1974

Lopez GP, Biebuyck HA, Frisbie CD, Whitesides GM (1993) Imaging of features on surfaces by condensation figures. Science 260(5108):647–649

Abbott NL, Folkers JP, Whitesides GM (1992) Manipulation of the wettability of surfaces on the 0.1- micrometer to 1- micrometer scale through micromachining and molecular self-assembly. Science 257(5075):1380–1382

Varanasi KK, Hsu M, Bhate N, Yang WS, Deng T (2009) Spatial control in the heterogeneous nucleation of water. Appl Phys Lett 95(9):094101. https://doi.org/10.1063/1.3200951

Betz AR, Xu J, Qiu HH, Attinger D (2010) Do surfaces with mixed hydrophilic and hydrophobic areas enhance pool boiling? Appl Phys Lett 97(14):141909. https://doi.org/10.1063/1.3485057

Park SY, Teitell MA, Chiou EP (2010) Single-sided continuous optoelectrowetting (SCOEW) for droplet manipulation with light patterns. Lab Chip 10(13):1655–1661

Mao B, Siddaiah A, Liao Y, Menezes PL (2020) Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: a review. J Manuf Process 53:153–173

Abed MM, Gaspari F, Kiani A (2020) Optical properties of Si/SiO2 nano structured films induced by laser plasma ionization deposition. Opt Commun 462:125297. https://doi.org/10.1016/j.optcom.2020.125297

Chen TC, Liu HT, Teng SH, Yan W, Yang HF, Li JD (2016) Water transport control on a patterned superhydrophobic surface via laser direct writing. J Vac Sci Technol A 34(6):061103. https://doi.org/10.1116/1.4966617

Guo YX, Hu RM, Zhou XL, Yu J, Wang LH (2019) A first principle study on the adsorption of H2O2 on CuO (111) and Ag/CuO (111) surface. Appl Surf Sci 479:989–996

Ferrer MM, Fabris GSL, Faria BVD, Martins JBL, Moreira ML, Sambrano JR (2019) Quantitative evaluation of the surface stability and morphological changes of Cu2O particles. Heliyon 5(10):e02500. https://doi.org/10.1016/j.heliyon.2019.e02500

Yong JL, Chen F, Yang Q, Fang Y, Huo JL, Hou JX (2015) Femtosecond laser induced hierarchical ZnO superhydrophobic surfaces with switchable wettability. Chem Commun 51(48):9813–9816

Bizi-Bandoki P, Valette S, Audouard E, Benayoun S (2013) Time dependency of the hydrophilicity and hydrophobicity of metallic alloys subjected to femtosecond laser irradiations. Appl Surf Sci 273:399–407

Chibowski E (2011) Apparent surface free energy of superhydrophobic surfaces. J Adhes Sci Technol 25(12):1323–1336

Altay BN, Ma RX, Fleming PD (2020) Surface free energy estimation: a new methodology for solid surfaces. Adv Mater Interfaces 7(6):1901570. https://doi.org/10.1002/admi.201901570

Lo CW, Chu YC, Yen MH, Lu MC (2019) Enhancing condensation heat transfer on three-dimensional hybrid surfaces. Joule 3(11):2806–2823

Acknowledgements

This research was financially supported by Fund of Hubei Provincial Education Department (D20191405, 20181401), the Open Fund of RAL of Northeastern University (2016001), and the Hubei Provincial Natural Science Foundation (ZRMS2019000729, 2017CFB685).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Joshua Tong.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lou, D., Mei, S., Wang, B. et al. Effect of stabilizing heat treatment on condensation heat transfer performance of laser micro-/nano-textured copper surface. J Mater Sci 56, 3981–3994 (2021). https://doi.org/10.1007/s10853-020-05454-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05454-0