Abstract

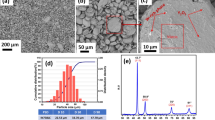

Additive manufacturing is a promising alternative method for fabricating components of Ni-based superalloys which are difficult to cast, form and join. However, typical thermal cycles associated with laser powder bed-fusion techniques suppress the formation of desirable microstructures containing γ′ particles, necessitating long-time post-process heat treatments. Here we report in-situ precipitation of γ′ (L12-ordered) particles and carbides during electron-beam powder bed-fusion of Inconel-738. The γ′ particles are homogenously distributed across the build and exhibit a multimodal size distribution. Based on atom-probe microscopy, we propose a eutectic reaction and multiple nucleation, growth, coarsening and dissolution bursts during thermal cycling as formation mechanism.

Similar content being viewed by others

References

Egbewande AT, Zhang HR, Sidhu RK, Ojo OA (2009) Improvement in laser weldability of INCONEL 738 superalloy through microstructural modification. Metal Mater Trans A 40:2694–2704

El-Awadi GA, Abdel-Samad S, Elshazly ES (2016) Hot corrosion behavior of Ni based Inconel 617 and Inconel 738 superalloys. Appl Surf Sci 378:224–230

Ojo OA, Richards NL, Chaturvedi MC (2004) Contribution of constitutional liquation of gamma prime precipitate to weld HAZ cracking of cast Inconel 738 superalloy. Scr Mater 50:641–646

Zhong M, Sun H, Liu W, Zhu X, He J (2005) Boundary liquation and interface cracking characterization in laser deposition of Inconel 738 on directionally solidified Ni-based superalloy. Scr Mater 53:159–164

Egbewande AT, Buckson RA, Ojo OA (2010) Analysis of laser beam weldability of Inconel 738 superalloy. Mater Char 61:569–574

Frazier WE (2014) Metal additive manufacturing: a review. J Mater Eng Perform 23:1917–1928

Muñiz-Lerma JA, Tian Y, Wang X, Gauvin R, Brochu M (2019) Microstructure evolution of Inconel 738 fabricated by pulsed laser powder bed fusion. Prog Add Manuf 4:97–107

Dutta B, Babu SS, Jared BH (2019) Science Technology and Applications of Metals in Additive Manufacturing. Elsevier, Amsterdam

Ramakrishnan A, Dinda GP (2019) Direct laser metal deposition of Inconel 738. Mater Sci Eng A 740–741:1–13

Sames WJ, Unocic KA, Helmreich GW, Kirka MM, Medina F, Dehoff RR, Babu SS (2017) Feasibility of in situ controlled heat treatment (ISHT) of Inconel 718 during electron beam melting additive manufacturing. Addit Manuf 13:156–165

Tian Y, McAllister D, Colijn H, Mills M, Farson DF, Nordin MC, Babu SS (2014) Rationalization of microstructure heterogeneity in INCONEL 718 builds made by the direct laser additive manufacturing process. Metall Mater Trans A 45:4470–4483

Murr LE, Gaytan SM, Ramirez DA, Martinez E, Hernandez J, Amato KN, Shindo PW, Medina FR, Wicker RB (2012) Metal fabrication by additive manufacturing using laser and electron beam melting technologies. J Mater Sci Technol 28:1–14

Ojo OA, Richards NL, Chaturvedi MC (2004) On incipient melting during high temperature heat treatment of cast Inconel 738 superalloy. J Mater Sci 39:7401–7404

Gault B, Moody MP, Cairney JM, Ringer SP (2012) Atom probe microscopy. Springer, New York

David SA, Vitek JM (1989) Correlation between solidification parameters and weld microstructures. Int Mater Rev 34:213–245

Fernandez R, Lecomte JC, Kattamis TZ (1978) Effect of solidification parameters on the growth geometry of MC carbide in IN-100 dendritic monocrystals. Metall Trans A 9:1381–1386

Sidhu RK, Ojo OA, Chaturvedi MC (2007) Microstructural analysis of laser-beam-welded directionally solidified INCONEL 738. Metall Mater Trans A 38:858–870

Babu SS, Raghavan N, Raplee J, Foster SJ, Frederick C, Haines M, Dinwiddie R, Kirka MK, Plotkowski A, Lee Y, Dehoff RR (2018) Additive manufacturing of nickel superalloys: opportunities for innovation and challenges related to qualification. Metal Mater Trans A 49:3764–3780

Donachie MJ, Donachie SJ (2002) Superalloys a technical guide. ASM International, Cleveland

Wang Y, Khachaturyan AG (1995) Shape instability during precipitate growth in coherent solids. Acta Metall Mater 43:1837–1857

Hagel WC, Beattie HJ "Iron and Steel Institute Special Report." London 64 (1959) 98

Sidhu RK, Richards NL, Chaturvedi MC (2007) Post-weld heat treatment cracking in autogenous GTA welded cast Inconel 738LC superalloy. Mater Sci Technol 23:203–213

Xu J, Lin X, Guo P, Hu Y, Wen X, Xue L, Liu J, Huang W (2017) The effect of preheating on microstructure and mechanical properties of laser solid forming IN-738LC alloy. Mater Sci Eng A 691:71–80

Sarosi PM, Wang B, Simmons JP, Wang Y, Mills MJ (2007) Formation of multimodal size distributions of γ′ in a nickel-base superalloy during interrupted continuous cooling. Scr Mater 57:767–770

Babu SS, Miller MK, Vitek JM, David SA (2001) Characterization of the microstructure evolution in a nickel base superalloy during continuous cooling conditions. Acta Mater 49:4149–4160

Pareige C, Soisson F, Martin G, Blavette D (1999) Ordering and phase separation in Ni–Cr–Al: Monte Carlo simulations vs three-dimensional atom probe. Acta Mater 47:1889–1899

Radis R, Schaffer M, Albu M, Kothleitner G, Pölt P, Kozeschnik E (2009) Multimodal size distributions of γ′ precipitates during continuous cooling of UDIMET 720 Li. Acta Mater 57:5739–5747

Acknowledgements

Funding by the AUSMURI program, Department of Industry, Innovation and Science, Australia is acknowledged. Sample was kindly provided by Miss Sabina Kumar, The University of Tennessee, Knoxville. A/Prof. Sophie Primig is supported under the Australian Research Council’s DECRA (project number DE180100440) and the UNSW Scientia Fellowship schemes. The authors acknowledge the technical assistance and use of facilities supported by Microscopy Australia at the Electron Microscope Unit at the Mark Wainwright Analytical Centre at UNSW and Sydney Microscopy & Microanalysis at the University of Sydney. The research at The University of Tennessee, Knoxville is partly sponsored by the ONR award number N00014-18–1-2794. Any opinions, findings and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the ONR. Part of the research at Oak-Ridge National Lab was supported by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office, under contract DE-AC05-00OR22725 with UT-Battelle, LLC.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Haghdadi, N., Whitelock, E., Lim, B. et al. Multimodal γ′ precipitation in Inconel-738 Ni-based superalloy during electron-beam powder bed fusion additive manufacturing. J Mater Sci 55, 13342–13350 (2020). https://doi.org/10.1007/s10853-020-04915-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04915-w