Abstract

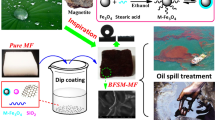

Large amount of oil leakage and organic wastewater discharge have greatly harmed the natural environment and human health. Therefore, researchers urgently need an effective method to address this problem. Superwetting materials can provide people with a good way to solve the problem because of their special selective wettability. In this report, a kind of green, fluorine-free, durable and low-cost superhydrophobic magnetic sponge was prepared by Fe3O4 particles and stearic acid. It can be controlled by changing the magnetic field to avoid direct contact with toxic and harmful solvents by the operator. The prepared material can be soaked for 7 days under harsh conditions of an acid solution, an alkali solution and a salt solution, and still maintain superhydrophobic property. Moreover, it is loaded with a weight of 200 g for 80 cycles of extrusion deformation (the compressive strain is 75%), and then with superhydrophobic properties. The sponge can be used for the separation of oil–water mixtures and oil–water emulsion purification with a separation efficiency of over 90%. It is worth mentioning that crude oil emulsion can be separated and purified by this material. The magnetic superhydrophobic sponge is prepared by simple and easy-to-operate method, which can be prepared in large scale. These results provide useful avenue utilization for the sponge, demonstrating the potential applications for oil–water separation, sewage purification, emulsion purification and oil spill collection.

Similar content being viewed by others

References

Coelho G, Clark J, Aurand D (2013) Toxicity testing of dispersed oil requires adherence to standardized protocols to assess potential real world effects. Environ Pollut 177:185–188

Tao M, Xue L, Liu F, Jiang L (2014) An intelligent superwetting PVDF membrane showing switchable transport performance for oil/water separation. Adv Mater 26:2943–2948

Hao W, Xu J, Li R, Zhao X, Yang W (2019) Developing superhydrophobic rock wool for high-viscosity oil/water separation. Chem Eng J 368:837–846

Jiang C, Liu W, Yang M, Zhang F, Shi H, Xie Y, Wang Z (2019) Robust fabrication of superhydrophobic and photocatalytic self-cleaning cotton textiles for oil–water separation via thiol-ene click reaction. J Mater Sci 54:7369–7382. https://doi.org/10.1007/s10853-019-03373-3

Liao X, Li H, Su X, Zhan H, Lai X, Zeng X (2019) Mussel-inspired cotton fabric with pH-responsive superwettability for bidirectional oil–water separation. J Mater Sci 54:3648–3660. https://doi.org/10.1007/s10853-018-3085-7

Xie A, Cui J, Yang J, Chen Y, Dai J, Lang J, Lia C (2019) Photo-Fenton self-cleaning membranes with robust flux recovery for an efficient oil/water emulsion separation. J Mater Chem A 7:8491–8502

Wang J, He J, Ma L, Zhang Y, Zhao Y, Zhou Y, Li K, Qu M (2019) Buoyant and durable oil/water separation mesh for continuous and efficient collection of both oil slick and underwater oil leakage. Sep Purif Technol 229:115795

Phanthong P, Reubroycharoen P, Kongparakul SE, Samart C, Wang ZD, Hao XG, Abudula A, Guan GQ (2019) Fabrication and evaluation of nanocellulose sponge for oil/water separation. Carbohydr Polym 190:184–189

Yue X, Li Z, Zhang T, Yang D, Qiu F (2019) Design and fabrication of superwetting fiber-based membranes for oil/water separation applications. Chem Eng J 364:292–309

Wu L, Zhang J, Li B, Wang A (2014) Mechanical- and oil-durable superhydrophobic polyester materials for selective oil absorption and oil/water separation. J Colloid Interface Sci 413:112–117

Liu X, Ge L, Li W, Wang X, Li F (2015) Layered double hydroxide functionalized textile for effective oil/water separation and selective oil adsorption. ACS Appl Mater Interfaces 71:791–800

Gao J, Li B, Wang L, Huang X, Xue H (2018) Flexible membranes with a hierarchical nanofiber/microsphere structure for oil adsorption and oil/water separation. J Ind Eng Chem 68:416–424

Ge B, Han L, Liang X, Li F, Pu X, Zhu X, Zhang Z, Shao X, Jin C, Li W (2018) Fabrication of superhydrophobic Cu-BiOBr surface for oil/water separation and water soluble pollutants degradation. Appl Surf Sci 462:583–589

Yong J, Yang Q, Guo C, Chen F, Houa X (2019) A review of femtosecond laser-structured superhydrophobic or underwater superoleophobic porous surfaces/materials for efficient oil/water separation. RSC Adv 9:12470–12495

Qu M, Ma L, Wang J, Zhang Y, Zhao Y, Zhou Y, Liu X, He J (2019) Multifunctional superwettable material with smart ph responsiveness for efficient and controllable oil/water separation and emulsified wastewater purification. ACS Appl Mater Interfaces 11:24668–24682

Tian Y, Su B, Jiang L (2014) Review: interfacial material system exhibiting superwettability. Adv Mater 26:6872–6897

Sun X, Xue B, Tian Y, Qin S, Xie L (2018) 3D porous poly(l-lactic acid) materials with controllable multi-scale microstructures and their potential application in oil-water separation. Appl Surf Sci 462:633–640

Gu J, Gu H, Zhang Q, Zhao Y, Li N, Xiong J (2018) Sandwich-structured composite fibrous membranes with tunable porous structure for waterproof, breathable, and oil-water separation applications. J Colloid Interface Sci 514:386–395

Huang P, Wu F, Shen B, Ma X, Zhao Y, Wu M, Wang J, Liu Z, Luo H, Zheng W (2019) Bio-inspired lightweight polypropylene foams with tunable hierarchical tubular porous structure and its application for oil-water separation. Chem Eng J 370:1322–1330

Peng M, Zhu Y, Li H, He K, Zeng G, Chen A, Huang Z, Huang T, Yuan L, Chen G (2019) Synthesis and application of modified commercial sponges for oil-water separation. Chem Eng J 373:213–226

Lv X, Tian D, Peng Y, Li J, Jiang G (2019) Superhydrophobic magnetic reduced graphene oxide-decorated foam for efficient and repeatable oil–water separation. Appl Surf Sci 466:937–945

Liu C, Fang Y, Miao X, Pei Y, Yan Y, Xiao W, Wu L (2019) Facile fabrication of superhydrophobic polyurethane sponge towards oil-water separation with exceptional flame-retardant performance. Sep Purif Technol 229:115801–115811

Marzooq H, Naser HA, Elkanzi EM (2019) Quantifying exposure levels of coastal facilities to oil spills in Bahrain, Arabian Gulf. Environ Monit Assess 191:160–176

Tang D, Sun J, Zhou L, Wang S, Singh RP, Pan G (2019) Ecological response of phytoplankton to the oil spills in the oceans. Geomat Nat Haz Risk 10:853–872

Li Z, He F, Lin B (2019) Preparation of magnetic superhydrophobic melamine sponge for oil–water separation. Powder Technol 345:571–579

Hu J, Zhu J, Jiang C, Guo T, Song Q, Xie L (2019) Facile preparation of durably magnetic superhydrophobic sponge and its application in oil-water separation. Colloid Surface A 577:429–439

Yang C, Wu L, Li G (2018) Magnetically responsive superhydrophobic surface: in situ reversible switching of water droplet wettability and adhesion for droplet manipulation. ACS Appl Mater Interfaces 10:20150–20158

Li J, Tenjimbayashi M, Zacharia N, Shiratori S (2018) One step dipping fabrication of Fe3O4/PVDF–HFP composite 3D porous sponge for magnetically controllable oil–water separation. ACS Sustain Chem Eng 6:10706–10713

Liu L, Pan Y, Bhushan B, Zhao X (2019) Mechanochemical robust, magnetic-driven, superhydrophobic 3D porous materials for contaminated oil recovery. J Colloid Interface Sci 538:25–33

Li Z, Wu H, Chen W, He F, Li D (2019) Preparation of magnetic superhydrophobic melamine sponges for effective oil-water separation. Sep Purif Technol 212:40–50

Ran M, Zheng W, Wang H (2019) Fabrication of superhydrophobic surfaces for corrosion protection: a review. Mater Sci Technol-Lond 3:313–326

He M, Xu M, Zhang L (2013) Controllable stearic acid crystal induced high hydrophobicity on cellulose film surface. ACS Appl Mater Interfaces 5:585–591

He J, Zhang Y, Zhou Y, Wang J, Zhou Y, Ma L, Abbas A, Qu M (2019) A facile approach to fabricate the durable and buoyant superhydrophobic fabric for efficient oil/Water separation. Fiber Polym 20:1003–1010

Hou X, Wang X, Mi W (2018) Progress in Fe3O4-based multiferroic heterostructures. J Alloys Compd 765:1127–1138

Zhang X, Mo J, Si Y, Guo Z (2018) How does substrate roughness affect the service life of a superhydrophobic coating? Appl Surf Sci 441:491–499

Shang B, Chen M, Wu L (2018) Fabrication of UV-triggered liquid-repellent coatings with long-term self-repairing performance. ACS Appl Mater Interfaces 10:31777–31783

Nadargi D, Jyoti G, Marioni MA, Romer S, Matam S, Koebel MM (2015) Methyltrimethoxysilane (MTMS)-based silica–iron oxide superhydrophobic nanocomposites. J Colloid Interface Sci 459:123–126

Wu L, Zhang J, Li B, Fan L, Li L, Wang A (2014) Facile preparation of super durable superhydrophobic materials. J Colloid Interface Sci 432:31–42

Zhao X, Li Y, Li B, Hu T, Yang Y, Li L, Zhang J (2019) Environmentally benign and durable superhydrophobic coatings based on SiO2 nanoparticles and silanes. J Colloid Interface Sci 542:8–14

Wang N, Tang L, Tong W, Xiong D (2018) Fabrication of robust and scalable superhydrophobic surfaces and investigation of their anti-icing properties. Mater Des 156:320–328

Wang P, Sun B, Yao T, Chen M, Fan X, Han H, Li L, Wang C (2017) A novel dissolution and resolidification method for preparing robust superhydrophobic polystyrene/silica composite. Chem Eng J 326:1066–1073

Su C, Yang H, Zhao H, Liu Y, Chen R (2017) Recyclable and biodegradable superhydrophobic and superoleophilic chitosan sponge for the effective removal of oily pollutants from water. Chem Eng J 330:423–432

Zhu J, Hu J, Peng T, Jiang C, Liu S, Li Y, Guo T, Xie L (2019) Superhydrophobic melamine-formaldehyde sponge functionalized by coupling agent-isocyanate siloxane as efficient absorbents for oil and organic solvents. Adv Mater Interfaces 6:1900025–1900036

Yang H, Ye S, Wang Y, Zhou J, Chen J, Zeng Q, Liang T (2019) Natural flexible superhydrophobic film derived from cajeput bark for oil/water separation. Mater Lett 238:198–201

Zhang L, Dong D, Shao L, Xia Y, Zeng T, Wang Y (2019) Cost-effective one-pot surface modified method to engineer a green superhydrophobic sponge for efficient oil/water mixtures as well as emulsions separation. Colloid Surface A 576:43–54

Yang J, Wang H, Tao Z, Liu X, Wang Z, Yue R, Cui Z (2019) 3D superhydrophobic sponge with a novel compression strategy for effective water-in-oil emulsion separation and its separation mechanism. Chem Eng J 359:149–158

Acknowledgements

The authors thank the National Natural Science Foundation of China (Grant Nos. 21473132), the Youth Innovation Team of Shaanxi Universities, the Shaanxi Provincial Science and Technology Department (Grant Nos. 2019JM-371), the Outstanding Youth Science Fund of Xi’an University of Science and Technology (Grant Nos. 2019YQ2-09) and Huyang Scholar Program of Xi’an University of Science and Technology for continuing financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, J., Zhang, Y., Wang, J. et al. Eco-friendly, magnetic-driven, superhydrophobic sponge for oil/water separation and emulsion purification. J Mater Sci 55, 6708–6720 (2020). https://doi.org/10.1007/s10853-020-04462-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04462-4