Abstract

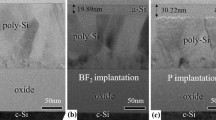

Silicon single crystals were irradiated at room temperature (RT) with single and dual low-velocity (i.e., 900 keV I) and high-velocity (i.e., 27 MeV Fe or 36 MeV W) ion beams in order to study synergistic effects between nuclear and electronic energy losses in semiconductors. The damage created by irradiation was quantified by using Rutherford backscattering spectrometry in the channeling mode and Raman spectroscopy, and it was visualized using transmission electron microscopy. Whereas single low-velocity ion irradiation leads to amorphization of the surface layer of Si crystals, the use of a dual low- and high-velocity ion beam prevents this phase transformation. However, a remaining disorder exists, the level of which depends on the ratio of the high- to low-velocity ion fluxes. The higher the ratio (1.6 in the present case), the lower the disorder level, with a 30% integrated disorder instead of 100% upon single low-energy irradiation. These results provide evidence that ionization-induced disorder annealing can occur at RT in Si.

Similar content being viewed by others

References

Wesch W, Schnohr CS (2016) Ion beam modification of solids. Springer, Cham

Weber WJ, Duffy DM, Thomé L, Zhang Y (2015) The role of electronic energy loss in ion beam modification of materials. Curr Opin Solid State Mater Sci 19:1–11

Zarkadoula E, Jin K, Zhang Y, Weber WJ (2017) Synergistic effects of nuclear and electronic energy loss in KTaO3 under ion irradiation. AIP Adv 7:015016

Sall M, Monnet I, Grygiel C, Banetat B, Lebius H, Leclerc S, Balanzat E (2013) Synergy between electronic and nuclear energy losses for color center creation in AlN. EPL 102:26002

Thomé L, Debelle A, Garrido F, Trocellier P, Serruys Y, Velisa G, Miro S (2013) Combined effects of nuclear and electronic energy losses in solids irradiated with a dual-ion beam. Appl Phys Lett 102:141906

Zhang Y, Sachan R, Pakarinen OH, Chisholm MF, Liu P, Xue H, Weber WJ (2015) Ionization-induced annealing of pre-existing defects in silicon carbide. Nat Commun 6:8049–8055

Gutierrez G, Gosset D, Bricout M, Onofri C, Debelle A (2019) Effect of coupled electronic and nuclear energy deposition on strain and stress levels in UO2. J Nucl Mater 519:52–56

Hull R (1999) Properties of crystalline silicon. Univ. Virginia, INSPEC, London

Thompson SE, Parthasarathy S (2006) Moore’s law: the future of Si microelectronics. Mater Today 9:20–25

Venema L (2011) Silicon electronics and beyond. Nature 479:309. https://doi.org/10.1038/479309a

Dimov N, Xia Y, Yoshio M (2007) Practical silicon-based composite anodes for lithium-ion batteries: fundamental and technological features. J Power Sources 171:886–893

Zuo X, Zhu J, Müller-Buschbaum P, Cheng YJ (2017) Facile synthesis of porous SnSb alloy anode for Li-ion battery. Nano Energy 31:113–143

Moll M (2018) Displacement damage in silicon detectors for high energy physics. IEEE Trans Nucl Sci 65:1561–1582

Breese MBH, Mangaiyarkarasi D, Teo EJ, Bettiol AA, Blackwood D (2006) Micro‐patterned porous silicon using proton beam writing. AIP Conference Proceedings 866:269. https://doi.org/10.1063/1.2401510

Griffioen CC, Evans JH, De Jong P, Van C, Veen A (1987) Helium desorption/permeation from bubbles in silicon: a novel method of void production. Nucl Instrum Methods B 27:417–420

Maleville C, Aspar B, Poumeyrol T, Moriceau H, Bruel M, Auberton-Herve AJ, Bargen T (1997) Wafer bonding and H-implantation mechanisms involved in the smart-cut technology. Mater Sci Eng, B 46:14–19

Cherkashin N, Darras FX, Pochet P, Reboh S, Ratel-Ramond N, Claverie A (2015) Modelling of point defect complex formation. Acta Mater 99:187–195

Hu ZG, Tan ZY, Lin Z, Chen J, Wang BS, Tian LF, Zheng RT, Chen YC, Cheng GA (2019) Cu ion implantation improves the performance of Si film anode used in lithium ion battery. Nucl Instrum Methods B 440:191–196

Williams JS, Azevedo M, Bernas H, Fortuna F (2010) Materials science with ion beams. In: Bernas H (ed) Topics of applied physics, vol 116. Springer, Berlin, Heidelberg, p 73

Pelaz L, Marqués LA, Barbolla J (2004) Ion-beam-induced amorphization and recrystallization in silicon. J Appl Phys 96:5947–5958

Edmondson PD, Riley DJ, Birtcher RC, Donnelly SE (2009) Amorphization of crystalline Si due to heavy and light ion irradiation. J Appl Phys 106:043505

Linnros J, Svensson B, Homén G (1984) Ion-beam-induced epitaxial regrowth of amorphous layers in silicon on sapphire. Phys Rev B 30:3629–3636

Priolo F, Rimini E (1990) Ion-beam-induced epitaxial crystallization and amorphization in silicon. Mater Sci Rep 5:321–379

Sahoo PK, Mohanty T, Kanjilal D, Pradhan A, Kulkarni VN (2007) Epitaxial recrystallization of amorphous Si layers by swift heavy ions. Nucl Instrum Methods B 257:244–248

Gentils A, Cabet C (2019) Investigating radiation damage in nuclear energy materials using JANNuS multiple ion beams. Nucl Instrum Methods B 447:107–112

Ziegler JF, Biersack JP, Littmark U (1985) The stopping and range of ions in solids. Pergamon, New York

Holmström E, Kuronen A, Nordlund K (2008) Threshold defect production in silicon determined by density functional theory molecular dynamics simulations. Phys Rev B 78:045202

Bacri CO, Bachelet C, Baumier C, Bourçois J, Delbecq L, Ledu D, Pauwels N, Picard S, Renouf S, Tanguy C (2017) SCALP, a platform dedicated to material modifications and characterization under ion beam. Nucl Instrum Methods B 406:48–52

Nowicki L, Turos A, Ratajczak R, Stonert A, Garrido F (2005) Modern analysis of ion channeling data by Monte Carlo simulations. Nucl Instrum Methods B 240:277–282

Nguyen TH, Garrido F, Debelle A, Mylonas S, Nowicki L, Thomé L, Bourçois J, Moeyaert J (2014) Radiation damage in urania crystals implanted with low-energy ions. Nucl Instrum Methods B 326:264–268

Xu Z, He Z, Song Y, Fu X, Rommel M, Luo X, Hartmaier A, Zhang J, Fang F (2018) Topic review: application of Raman spectroscopy characterization in micro/nano-machining. Micromachines 9:361–382

Vanecek M, Poruba A, Remes Z, Beck N, Nesladek M (1998) Optical properties of microcrystalline materials. J Non-Cryst Solids 227–230:967–972

Thomé L, Velisa G, Miro S, Debelle A, Garrido F, Sattonnay G, Mylonas S, Trocellier P, Serruys Y (2015) Recovery effects due to the interaction between nuclear and electronic energy losses in SiC irradiated with a dual-ion beam. J Appl Phys 117:105901

Mihai MD, Ionescu P, Pantelica D, Petrascu H, Cracium D, Cracium V, Vasiliu F, Vasile BS, Mercioniu I (2019) Annealing of preexisting defects in silicon single crystals by ion irradiation. Nucl Instrum Methods B 450:85–89

Debelle A, Backman M, Thomé L, Weber WJ et al (2012) Combined experimental and computational study of the recrystallization process induced by electronic interactions of swift heavy ions with silicon carbide crystals. Phys Rev B 86:100102

Debelle A, Thomé L, Monnet I, Garrido F, Pakarinen OH, Weber WJ (2019) Ionization-induced thermally activated defect-annealing process in SiC. Phys Rev Mater 3:063609

Acknowledgements

We acknowledge the French EMIR-A network for providing irradiation beam time, and we express our gratitude to the JANNuS-Saclay staff for their efficiency in performing the irradiation experiments. We also thank the SCALP staff for their help during the RBS/C measurements. I. M. wants to mention that part of her contribution was partially supported by the ANR funding “Investissements d’avenir” ANR-11-EQPX-0020 (Equipex GENESIS) by the “Fonds Européen de Développement Regional” and by the Region Basse-Normandie.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest at all.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thomé, L., Gutierrez, G., Monnet, I. et al. Ionization-induced annealing in silicon upon dual-beam irradiation. J Mater Sci 55, 5938–5947 (2020). https://doi.org/10.1007/s10853-020-04399-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04399-8