Abstract

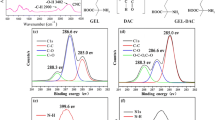

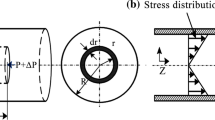

Early reports have demonstrated the feasibility of oxidized dextran/gelatin (OD/GEL) hydrogel for tissue engineering applications and the printability of OD/GEL hydrogel for 3D printing scaffolds, but adequate insight into fabricated OD/GEL scaffolds is lacking. In the present study, we prepared (cellulose nanocrystal) CNC/OD/GEL hydrogels and fabricated CNC/OD/GEL scaffolds by 3D printing. The properties of CNC/OD/GEL hydrogels were investigated by scanning electron microscopy (SEM) and Fourier transform infrared spectroscopy. The process of 3D printing of hydrogels was optimized, and the influence of the OD and CNC contents on the printability of CNC/OD/GEL hydrogels was investigated by studying the width of the printed filaments. The uniaxial compression test was performed to study the effects of the OD and CNC contents on the breaking strength and elastic modulus of CNC/OD/GEL scaffolds. In addition, the uniaxial compression test was also performed to determine the optimum mass ratio and crosslinking time of OD and GEL. The effects of the CNC content on scaffold shrinkage, scaffold swelling and scaffold porosity were further studied. The biocompatibility of a CNC0.4OD2G2 scaffold was also investigated by Cell Counting Kit-8 (CCK-8) and Hoechst 33342/PI double-staining assays. Collectively, the results confirmed the good potential of the CNC/OD/GEL hydrogels as 3D bioink for application in tissue repair.

Similar content being viewed by others

References

Wang YE, Li XP, Li CC, Yang MM, Wei QH (2015) Binder droplet impact mechanism on a hydroxyapatite microsphere surface in 3D printing of bone scaffolds. J Mater Sci 50(14):5014–5023. https://doi.org/10.1007/s10853-015-9050-9

Li J, Wang L, Dai L, Zhong L, Liu B, Ren J, Xu Y (2018) Synthesis and characterization of reinforced acrylate photosensitive resin by 2-hydroxyethyl methacrylate-functionalized graphene nanosheets for 3D printing. J Mater Sci 53(3):1874–1886. https://doi.org/10.1007/s10853-017-1432-8

Jiang YN, Zhou JP, Yang Z et al (2018) Dialdehyde cellulose nanocrystal/gelatin hydrogel optimized for 3D printing applications. J Mater Sci 53(16):11883–11900. https://doi.org/10.1007/s10853-018-2407-0

Ng WL, Chua CK, Shen YF (2019) Print me an organ! Why we are not there yet. Prog Polym Sci 97:10114501–10114545

Sweeney M, Campbell LL, Hanson J, Pantoya ML, Christopher GF (2017) Characterizing the feasibility of processing wet granular materials to improve rheology for 3D printing. J Mater Sci 52(22):13040–13053. https://doi.org/10.1007/s10853-017-1404-z

He Y, Yang FF, Zhao HM, Gao Q, Xia B, Fu JZ (2016) Research on the printability of hydrogels in 3d bioprinting. Sci Rep 6(6):29977–29986

Inzana JA, Diana O, Fuller SM et al (2014) 3D printing of composite calcium phosphate and collagen scaffolds for bone regeneration. Biomaterials 35(13):4026–4034

Xu Y, Wang X (2015) Fluid and cell behaviors along a 3D printed alginate/gelatin/fibrin channel. Biotechnol Bioeng 112(8):1683–1695

Ouyang L, Highley CB, Rodell CB, Sun W, Burdick JA (2016) 3D printing of shear-thinning hyaluronic acid hydrogels with secondary cross-linking. ACS Biomater Sci Eng 2(10):1743–1751

Strobel HA, Calamari EL, Alphonse B, Hookway TA, Rolle MW (2018) Fabrication of custom agarose wells for cell seeding and tissue ring self-assembly using 3D-printed molds. Jove-J Vis Exp 134:56616–56625

Ng WL, Yeong WY, Naing MW (2016) Polyelectrolyte gelatin-chitosan hydrogel optimized for 3D bioprinting in skin tissue engineering. Int J Bioprinting 2(1):53–62

Xiong S (2015) Degradation of silk fibroin and the application of 3D-printed bio-inducible scaffold in skin tissue engineering. Master Dissertation, Zhejiang A&F University, pp 15–24

Du Z, Li N, Hua Y, Shi Y, Bao C, Zhang H, Yang Y, Lin Q, Zhu L (2017) Physiological pH-dependent gelation for 3D printing based on the phase separation of gelatin and oxidized dextran. Chem Commun 53(97):13023–13026

Peppas NA, Hilt JZ, Khademhosseini A, Langer R (2010) Hydrogels in biology and medicine: from molecular principles to bionanotechnology. Adv Mater 18(11):1345–1360

Kim YB, Lee H, Kim GH (1944) Strategy to achieve highly porous/biocompatible macroscale cell blocks, using a collagen/genipin-bioink and an optimal 3D printing process. ACS Appl Mater Interfaces 8(47):32230–32240

Murphy CA, Collins MN (2016) Microcrystalline cellulose reinforced polylactic acid biocomposite filaments for 3D printing. Polym Compos 39(4):1311–1320

Nguyen D, Hägg DA, Forsman A (2017) Cartilage tissue engineering by the 3D bioprinting of iPS cells in a nanocellulose/alginate bioink. Sci Rep 7(1):658–667

Sawkins MJ, Mistry P, Brown BN, Shakesheff KM, Bonassar LJ, Yang J (2015) Cell and protein compatible 3D bioprinting of mechanically strong constructs for bone repair. Biofabrication 7(3):03500401–03500411

Inci I, Kirsebom H, Galaev IY, Bo M, Piskin E (2013) Gelatin cryogels crosslinked with oxidized dextran and containing freshly formed hydroxyapatite as potential bone tissue-engineering scaffolds. J Tissue Eng Regen Med 7(7):584–588

Geng XH, Yuan L, Mo XM (2013) Oxidized dextran/amino gelatin/hyaluronic acid semi-interpenetrating network hydrogels for tissue engineering application. Adv Mater Res 627:745–750

Lee JM, Ng WL, Yeong WY (2019) Resolution and shape in bioprinting: strategizing towards complex tissue and organ printing. Appl Phys Rev 6:01130701–01130716

Jiang Y, Zhou J, Zhang Q, Zhao G, Heng L, Chen D, Liu D (2017) Preparation of cellulose nanocrystals from Humulus japonicus stem and the influence of high temperature pretreatment. Carbohyd Polym 164:284–293

Sain M, Panthapulakkal S (2006) Bioprocess preparation of wheat straw fibers and their characterization. Ind Crops Prod 23(1):1–8

Means GE (1977) Reductive alkylation of amino groups. Methods Enzymol 47(6):469–478

Wei J (2016) Study on preparation of nanocellulose/PNIPAm composite hydrogels and PNIPAm-based composite nanogels with Ag. Master Dissertation, Zhejiang A&F University, pp 26–34

Pietrucha K, Safandowska M (2015) Dialdehyde cellulose-crosslinked collagen and its physicochemical properties. Process Biochem 50(12):2105–2111

Lu T, Li Q, Chen W, Yu H (2014) Composite aerogels based on dialdehyde nanocellulose and collagen for potential applications as wound dressing and tissue engineering scaffold. Compos Sci Technol 94(4):132–138

Kozyrev SV, Volovich IV (2012) The arrhenius formula in kinetic theory and Witten’s spectral asymptotics. J Phys A: Math Theor 44(21):21520201–21520210

Truhlar DG, Garrett BC (1980) Variational transition state theory. ACC Chem Res 35(3):159–189

Patenaude M, Campbell S, Kinio D, Hoare T (2014) Tuning gelation time and morphology of injectable hydrogels using ketone-hydrazide cross-linking. Biomacromol 15(3):781–790

Cheng J, Lin F, Liu H, Yan Y, Wang X, Zhang R, Xiong Z (2008) Rheological properties of cell-hydrogel composites extruding through small-diameter tips. J Manuf Sci Eng 130(2):0210141–0210145

Li H, Liu S, Li L (2016) Rheological study on 3D printability of alginate hydrogel and effect of graphene oxide. Int J Bioprinting 2(2):54–66

Zhang X, Yang Y, Yao J, Shao Z, Xin C (2014) Strong collagen hydrogels by oxidized dextran modification. ACS Sustain Chem Eng 2(5):1318–1324

Zhang W, Ullah I, Shi L, Zhang Y, Ou H, Zhou J, Li W (2019) Fabrication and characterization of porous polycaprolactone scaffold via extrusion-based cryogenic 3D printing for tissue engineering. Mater Des 180:10794601–10794610

Wang QQ, Sun JZ, Yao Q, Ji CC, Liu J, Zhu QQ (2018) 3D printing with cellulose materials. Cellulose 25(8):4275–4301

Jiang Y, Zhou J, Xv X, Liu D, Yang Z, Zhang Q, Shi H (2018) Preparation of cellulose nanofiber-reinforced gelatin hydrogel and optimization for 3D printing applications. BioResources 13(3):5909–5924

Pal N, Dubey P, Gopinath P, Pal K (2016) Combined effect of cellulose nanocrystal and reduced graphene oxide into poly-lactic acid matrix nanocomposite as a scaffold and its anti-bacterial activity. Int J Biol Macromol 95(4):94–105

Zhang L, Yang W, Tao K et al (2017) Sustained local release of NGF from a chitosan-sericin composite scaffold for treating chronic nerve compression. ACS Appl Mater Interfaces 9(4):3432–3444

Acknowledgements

This research was supported by the Natural Science Foundation of Yangzhou (YZ201976), the Top Talents Support Program of Yangzhou University, the City and University Cooperation Project and the Natural Science Foundation of China (81770018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, Y., Zhou, J., Shi, H. et al. Preparation of cellulose nanocrystal/oxidized dextran/gelatin (CNC/OD/GEL) hydrogels and fabrication of a CNC/OD/GEL scaffold by 3D printing. J Mater Sci 55, 2618–2635 (2020). https://doi.org/10.1007/s10853-019-04186-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04186-0