Abstract

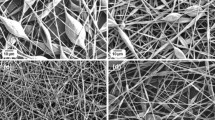

Polyamide-imides (PAIs) are highly desired in many applications because of their superior thermal and mechanical properties. In this work, PAI was prepared from an amide-containing diamine and dianhydride by polycondensation and thermal treatment. Both PAI films and aligned electrospun nanofibers (ANFs) were fabricated. FT-IR was used to determine the structure formation of PAI at different annealing temperatures. DSC and TGA were used to evaluate the thermal properties of PAI, while tensile test was applied to evaluate the mechanical properties of PAI films and ANFs. The results indicated that the PAI possessed both outstanding thermal stability and mechanical properties, which provide opportunities for applications in gas separation, high temperature filtration, reinforcement, etc.

Similar content being viewed by others

References

Terney S, Keating J, Zielinski J, Hakala J, Sheffer H (1970) Polyamide-imides. J Polym Sci Part A Polym Chem 8(3):683–692

Abbasi H, Antunes M, Velasco JI (2015) Influence of polyamide-imide concentration on the cellular structure and thermo-mechanical properties of polyetherimide/polyamide-imide blend foams. Eur Polym J 69:273–283

Wang Y, Jiang L, Matsuura T, Chung TS, Goh SH (2008) Investigation of the fundamental differences between polyamide-imide (PAI) and polyetherimide (PEI) membranes for isopropanol dehydration via pervaporation. J Membr Sci 318(1):217–226. https://doi.org/10.1016/j.memsci.2008.02.033

Lim SK, Setiawan L, Bae T-H, Wang R (2016) Polyamide-imide hollow fiber membranes crosslinked with amine-appended inorganic networks for application in solvent-resistant nanofiltration under low operating pressure. J Membr Sci 501:152–160

Feng Y, Xiong T, Xu H, Li C, Hou H (2016) Polyamide-imide reinforced polytetrafluoroethylene nanofiber membranes with enhanced mechanical properties and thermal stabilities. Mater Lett 182:59–62

Shen C, Khonsari MM, Spadafora M, Ludlow C (2016) Tribological performance of polyamide-imide seal ring under seawater lubrication. Tribol Lett 62(3):39

Ding Y, Hou H, Zhao Y, Zhu Z, Fong H (2016) Electrospun polyimide nanofibers and their applications. Prog Polym Sci 61:67–103. https://doi.org/10.1016/j.progpolymsci.2016.06.006

Hou H, Xu W, Ding Y (2018) The recent progress on high-performance polymer nanofibers by electrospinning. J Jiangxi Normal Univ (Nat Sci) 42(6):551–564. https://doi.org/10.1039/C6TA10474F

Jiang S, Han D, Huang C, Duan G, Hou H (2018) Temperature-induced molecular orientation and mechanical properties of single electrospun polyimide nanofiber. Mater Lett 216:81–83

Chen D, Liu T, Zhou X, Tjiu WC, Hou H (2009) Electrospinning fabrication of high strength and toughness polyimide nanofiber membranes containing multiwalled carbon nanotubes. J Phys Chem B 113(29):9741–9748. https://doi.org/10.1021/jp9025128

Jian S, Liu S, Chen L, Zhou S, Fan P, Zeng Y, Hou H (2017) Nano-boria reinforced polyimide composites with greatly enhanced thermal and mechanical properties via in situ thermal conversion of boric acid. Compos Commun 3:14–17

Jian S, Zhu J, Jiang S, Chen S, Fang H, Song Y, Duan G, Zhang Y, Hou H (2018) Nanofibers with diameter below one nanometer from electrospinning. RSC Adv 8(9):4794–4802. https://doi.org/10.1039/C7RA13444D

Xu W, Yang T, Yu Y, Zhang C, Ding Y, Hou H (2018) The synthesis and characterization of polyimides from a novel synthesized 3,3′-(m-phenylene) dianhydride monomer. J Jiangxi Normal Univ (Nat Sci) 42(1):82–88. https://doi.org/10.1039/C6TA10474F

Miao Y-E, Zhu G-N, Hou H, Xia Y-Y, Liu T (2013) Electrospun polyimide nanofiber-based nonwoven separators for lithium-ion batteries. J Power Sour 226:82–86. https://doi.org/10.1016/j.jpowsour.2012.10.027

Xu H, Jiang S, Ding C, Zhu Y, Li J, Hou H (2017) High strength and high breaking load of single electrospun polyimide microfiber from water soluble precursor. Mater Lett 201:82–84

Jian S, Ding C, Yang T, Zhang C, Hou H (2018) Effect of trace diphenyl phosphate on mechanical and thermal performance of polyimide composite films. Compos Commun 7:42–46

Xu W, Yu Y, Yang T, Zhang C, Hou H (2018) The synthesis and properties of new 3D-printable polyimide. J Jiangxi Normal Univ (Nat Sci) 42(4):405–410. https://doi.org/10.1039/C6TA10474F

Hu Z, Li S, Zhang C (2007) Synthesis and properties of polyamide-imides containing fluorenyl cardo structure. J Appl Polym Sci 106(4):2494–2501

Liaw D-J, Liaw B-Y (2001) Synthesis and characterization of new polyamide-imides containing pendent adamantyl groups. Polymer 42(2):839–845. https://doi.org/10.1016/S0032-3861(00)00379-7

Liaw D-J, Hsu P-N, Liaw B-Y (2001) Synthesis and characterization of novel polyamide-imides containing noncoplanar 2,2′-dimethyl-4,4′-biphenylene unit. J Polym Sci Part A Polym Chem 39(1):63–70. https://doi.org/10.1002/1099-0518(20010101)39:1%3c63:AID-POLA70%3e3.0.CO;2-X

Liaw D-J, Hsu P-N, Chen W-H, Lin S-L (2002) High glass transitions of new polyamides, polyimides, and poly(amide–imide)s containing a triphenylamine group: synthesis and characterization. Macromolecules 35(12):4669–4676. https://doi.org/10.1021/ma001523u

Park S-J, Yop Rhee K, Jin F-L (2015) Improvement of hydrophilic properties of electrospun polyamide-imide fibrous mats by atmospheric-pressure plasma treatment. J Phys Chem Solids 78:53–58. https://doi.org/10.1016/j.jpcs.2014.11.001

Jang WG, Jeon KS, Byun HS (2013) The preparation of porous polyamide-imide nanofiber membrane by using electrospinning for MF application. Desalin Water Treat 51(25–27):5283–5288. https://doi.org/10.1080/19443994.2013.768755

G-y Heo, Y-t Hong, S-j Park (2012) Preparation and characterization of nickel-coated carbon nanofibers produced from the electropsinning of polyamideimide precursor. Macromol Res 20(5):503–507. https://doi.org/10.1007/s13233-012-0075-5

Wang M, Jin H-J, Kaplan DL, Rutledge GC (2004) Mechanical properties of electrospun silk fibers. Macromolecules 37(18):6856–6864

Jiang S, Chen Y, Duan G, Mei C, Greiner A, Agarwal S (2018) Electrospun nanofiber reinforced composites: a review. Polym Chem 9:2685–2720. https://doi.org/10.1039/C8PY00378E

Pai C-L, Boyce MC, Rutledge GC (2011) Mechanical properties of individual electrospun PA 6 (3) T fibers and their variation with fiber diameter. Polymer 52(10):2295–2301

Koosha M, Mirzadeh H (2015) Electrospinning, mechanical properties, and cell behavior study of chitosan/PVA nanofibers. J Biomed Mater Res A 103(9):3081–3093

Tan E, Lim C (2006) Mechanical characterization of nanofibers—a review. Compos Sci Technol 66(9):1102–1111

Arinstein A, Zussman E (2011) Electrospun polymer nanofibers: mechanical and thermodynamic perspectives. J Polym Sci Part B Polym Phys 49(10):691–707

Jiang S, Duan G, Chen L, Hu X, Hou H (2015) Mechanical performance of aligned electrospun polyimide nanofiber belt at high temperature. Mater Lett 140:12–15. https://doi.org/10.1016/j.matlet.2014.11.003

Chen L, Jiang S, Chen J, Chen F, He Y, Zhu Y, Hou H (2015) Single electrospun nanofiber and aligned nanofiber belts from copolyimide containing pyrimidine units. New J Chem 39(11):8956–8963. https://doi.org/10.1039/C5NJ01941A

Chen S, Hu P, Greiner A, Cheng C, Cheng H, Chen F, Hou H (2008) Electrospun nanofiber belts made from high performance copolyimide. Nanotechnology 19(1):015604. https://doi.org/10.1088/0957-4484/19/01/015604

He Y, Han D, Chen J, Ding Y, Jiang S, Hu C, Chen S, Hou H (2014) Highly strong and highly tough electrospun polyimide/polyimide composite nanofibers from binary blend of polyamic acids. RSC Adv 4(104):59936–59942

Scheiner S, Kar T (2002) Red- versus blue-shifting hydrogen bonds: are there fundamental distinctions? J Phys Chem A 106(9):1784–1789. https://doi.org/10.1021/jp013702z

Chocholoušová J, Špirko V, Hobza P (2004) First local minimum of the formic acid dimer exhibits simultaneously red-shifted O–H···O and improper blue-shifted C–H···O hydrogen bonds. PCCP 6(1):37–41. https://doi.org/10.1039/B314148A

Joseph J, Jemmis ED (2007) Red-, blue-, or no-shift in hydrogen bonds: a unified explanation. J Am Chem Soc 129(15):4620–4632. https://doi.org/10.1021/ja067545z

Snyder R, Thomson B, Bartges B, Czerniawski D, Painter P (1989) FTIR studies of polyimides: thermal curing. Macromolecules 22(11):4166–4172

Yang H, Jiang S, Fang H, Hu X, Duan G, Hou H (2018) Molecular orientation in aligned electrospun polyimide nanofibers by polarized FT-IR spectroscopy. Spectrochim Acta Part A Mol Biomol Spectrosc 200:339–344. https://doi.org/10.1016/j.saa.2018.04.045

Zhang H, Jiang S, Duan G, Li J, Liu K, Zhou C, Hou H (2014) Heat-resistant polybenzoxazole nanofibers made by electrospinning. Eur Polym J 50:61–68

Huang CB, Chen SL, Reneker DH, Lai CL, Hou HQ (2006) High-strength mats from electrospun poly(p-phenylene biphenyltetracarboximide) nanofibers. Adv Mater 18(5):668. https://doi.org/10.1002/adma.200501806

Jiang S, Duan G, Chen L, Hu X, Hou H (2015) Mechanical performance of aligned electrospun polyimide nanofiber belt at high temperature. Mater Lett 140:12–15

Bazbouz MB, Stylios GK (2010) The tensile properties of electrospun nylon 6 single nanofibers. J Polym Sci Pt B-Polym Phys 48(15):1719–1731. https://doi.org/10.1002/polb.21993

Hwang KY, Kim S-D, Kim Y-W, Yu W-R (2010) Mechanical characterization of nanofibers using a nanomanipulator and atomic force microscope cantilever in a scanning electron microscope. Polym Test 29(3):375–380. https://doi.org/10.1016/j.polymertesting.2010.01.002

Jiang SH, Hou HQ, Greiner A, Agarwal S (2012) Tough and transparent nylon-6 electrospun nanofiber reinforced melamine-formaldehyde composites. ACS Appl Mater Interfaces 4(5):2597–2603. https://doi.org/10.1021/am300286m

Chen D, Liu TX, Zhou XP, Tjiu WC, Hou HQ (2009) Electrospinning fabrication of high strength and toughness polyimide nanofiber membranes containing multiwalled carbon nanotubes. J Phys Chem B 113(29):9741–9748. https://doi.org/10.1021/jp9025128

Peng L, Jiang SH, Seuss M, Fery A, Lang G, Scheibel T, Agarwal S (2016) Two-in-one composite fibers with side-by-side arrangement of silk fibroin and poly(l-lactide) by electrospinning. Macromol Mater Eng 301(1):48–55. https://doi.org/10.1002/mame.201500217

Feng Y, Xiong T, Jiang S, Liu S, Hou H (2016) Mechanical properties and chemical resistance of electrospun polyterafluoroethylene fibres. RSC Adv 6(29):24250–24256. https://doi.org/10.1039/C5RA27676D

Liverani L, Boccaccini AR (2016) Versatile production of poly(epsilon-caprolactone) fibers by electrospinning using benign solvents. Nanomaterials (Basel, Switzerland) 6(4):75. https://doi.org/10.3390/nano6040075

Tan EPS, Ng SY, Lim CT (2005) Tensile testing of a single ultrafine polymeric fiber. Biomaterials 26(13):1453–1456. https://doi.org/10.1016/j.biomaterials.2004.05.021

Jiang SH, Duan GG, Zussman E, Greiner A, Agarwal S (2014) Highly flexible and tough concentric triaxial polystyrene fibers. ACS Appl Mater Interfaces 6(8):5918–5923. https://doi.org/10.1021/am500837s

Inai R, Kotaki M, Ramakrishna S (2005) Structure and properties of electrospun PLLA single nanofibres. Nanotechnology 16(2):208–213. https://doi.org/10.1088/0957-4484/16/2/005

Zhang HA, Jiang SH, Duan GG, Li JH, Liu KM, Zhou CY, Hou HQ (2014) Heat-resistant polybenzoxazole nanofibers made by electrospinning. Eur Polym J 50:61–68. https://doi.org/10.1016/j.eurpolymj.2013.10.029

Chen K, Zhang S, Liu B, Mao X, Sun G, Yu J, Aldeyab S, Ding B (2014) Large-scale fabrication of highly aligned poly(m-phenylene isophthalamide) nanofibers with robust mechanical strength. Rsc Adv 4(86):45760–45767

Acknowledgements

Natural Science Foundation of Jiangsu Province of China (BK20180770); National Natural Science Foundation of China (51803093, 21574060 and 21374044); Major Special Projects of Jiangxi Provincial Department of Science and Technology (20114ABF05100); Technology Plan Landing Project of Jiangxi Provincial Department of Education (GCJ2011-24).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict.

Rights and permissions

About this article

Cite this article

Duan, G., Liu, S., Jiang, S. et al. High-performance polyamide-imide films and electrospun aligned nanofibers from an amide-containing diamine. J Mater Sci 54, 6719–6727 (2019). https://doi.org/10.1007/s10853-019-03326-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03326-w