Abstract

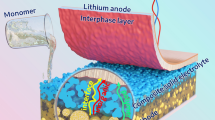

Silica-based material is regarded as one of the most potential anode materials for lithium ion batteries (LIBs) because of its high specific capacity, low discharge potential, and inexpensive cost. However, low conductivity and poor mechanical property block its practical application. In this work, we adopted a facile method to prepare attapulgite (AT)/polyacrylonitrile (PAN) aerogel precursor and then the precursor was pre-oxidated and carbonized. The natural porous AT with nanofiber structure was used to provide high specific capacity. In addition, PAN was introduced to improve mechanical performance and enhance the electrochemical conductivity. This feasible method could form in situ continuous carbonized phase network structure, which impeded large volume expansion and improved electrochemical performance. As active anode materials of LIBs, the carbonized AT-based aerogels exhibited average discharge capacity of 534.6 mAh g−1 at 100 mA g−1 after 50 cycles and Coulombic efficiency reached over 97%. Overall, the fabrication approach is cost-effective and can be used on a large scale, which may fully take advantage of low-cost AT clay and PAN.

Similar content being viewed by others

References

Ryu J, Hong D, Choi S, Park S (2016) Synthesis of ultrathin Si nanosheets from natural clays for lithium-ion battery anodes. ACS Nano 10:2843–2851

An W, Fu J, Su J et al (2017) Mesoporous hollow nanospheres consisting of carbon coated silica nanoparticles for robust lithium-ion battery anodes. J Power Sources 345:227–236

Park J, Yu BC, Park JS, Choi JW, Kim C, Sung YE, Goodenough JB (2017) Tungsten disulfide catalysts supported on a carbon cloth interlayer for high performance Li–S battery. Adv Energy Mater 7:1602567–1602572

Jung HG, Kim J, Scrosati B, Sun YK (2011) Micron-sized, carbon-coated Li4Ti5O12 as high power anode material for advanced lithium batteries. J Power Sources 196:7763–7766

Andreev YG, Bruce PG (2016) Size and shape of graphene layers in commercial carbon blacks established by Debye refinement. J Appl Crystallogr 49:24–30

Park HY, Kim MS, Bae TS, Yuan J, Yu JS (2016) Fabrication of binder-free pencil-trace electrode for lithium-ion battery: simplicity and high performance. Langmuir 32:4415–4423

Chang WS, Park CM, Kim JH, Kim YU, Jeong G, Sohn HJ (2012) Quartz (SiO2): a new energy storage anode material for Li-ion batteries. Energy Environ Sci 5:6895–6899

Wu C, Maier J, Yu Y (2015) Sn-based nanoparticles encapsulated in a porous 3D graphene network: advanced anodes for high-rate and long life li-ion batteries. Adv Funct Mater 25:3488–3496

Dou P, Cao Z, Wang C, Zheng J, Xu X (2017) Multilayer Zn-doped SnO2 hollow nanospheres encapsulated in covalently interconnected three-dimensional graphene foams for high performance lithium-ion batteries. Chem Eng J 320:405–415

Li W, Li M, Yang Z (2015) Carbon-coated germanium nanowires on carbon nanofibers as self-supported electrodes for flexible lithium-ion batteries. Small 11:2762–2767

Yang LY, Li HZ, Liu J, Sun ZQ, Tang SS, Lei M (2015) Dual yolk–shell structure of carbon and silica-coated silicon for high-performance lithium-ion batteries. Sci Rep 5:10908–10916

Yang T, Tian X, Li X, Wang K, Liu Z, Guo Q, Song Y (2017) Double core–shell Si@C@SiO2 for anode material of lithium-ion batteries with excellent cycling stability. Chem Eur J 23:2165–2170

Liu Q, Cui Z, Zou R, Zhang J, Xu K, Hu J (2017) Surface coating constraint induced anisotropic swelling of silicon in Si–Void@SiO x nanowire anode for lithium-ion batteries. Small 13:1603754–1603762

Chan CK, Peng H, Liu G, Mcilwrath K, Zhang X, Huggins RA, Cui Y (2008) High-performance lithium battery anodes using silicon nanowires. Nat Nanotechnol 3:31–35

Song T, Xia J, Lee JH et al (2010) Arrays of sealed silicon nanotubes as anodes for lithium ion batteries. Nano Lett 10:1710–1716

Sun L, Su T, Xu L, Du HB (2016) Preparation of uniform Si nanoparticles for high-performance Li-ion battery anodes. Phys Chem Chem Phys 18:1521–1525

Adpakpang K, Patil SB, Oh SM, Kang JH, Lacroix M, Hwang SJ (2016) Effective chemical route to 2D nanostructured silicon electrode material: phase transition from exfoliated clay nanosheet to porous Si nanoplate. Electrochim Acta 204:60–68

Liu N, Wu H, McDowell MT, Yao Y, Wang C, Cui Y (2012) A yolk–shell design for stabilized and scalable li-ion battery alloy anodes. Nano Lett 12:3315–3321

Liu X, Chen Y, Liu H, Liu ZQ (2017) SiO2@C hollow sphere anodes for lithium-ion batteries. J Mater Sci Technol 33:239–245

Yao Y, Zhang J, Xue L, Huang T, Yu A (2011) Carbon-coated SiO2 nanoparticles as anode material for lithium ion batteries. J Power Sources 196:10240–10243

Lv P, Zhao H, Wang J, Liu X, Zhang T, Xia Q (2013) Facile preparation and electrochemical properties of amorphous SiO2/C composite as anode material for lithium ion batteries. J Power Sources 237:291–294

Shi L, Wang W, Wang A, Yuan K, Jin Z, Yang Y (2016) Scalable synthesis of core–shell structured SiOx/nitrogen-doped carbon composite as a high-performance anode material for lithium-ion batteries. J Power Sources 318:184–191

Yan N, Wang F, Zhong H, Li Y, Wang Y, Hu L, Chen Q (2013) Hollow porous SiO2 nanocubes towards high-performance anodes for lithium-ion batteries. Sci Rep 3:1568–1573

Hao S, Wang Z, Chen L (2016) Amorphous SiO2 in tunnel-structured mesoporous carbon and its anode performance in Li-ion batteries. Mater Des 111:616–621

Gao B, Sinha S, Fleming L, Zhou O (2001) Alloy formation in nanostructured silicon. Adv Mater 13:816–819

He W, Tian H, Zhang S, Ying H, Meng Z, Han W (2017) Scalable synthesis of Si/C anode enhanced by FeSix nanoparticles from low-cost ferrosilicon for lithium-ion batteries. J Power Sources 353:270–276

Huo K, An W, Fu J, Gao B, Wang L, Peng X, Cheng GJ, Chu PK (2016) Mesoporous nitrogen-doped carbon hollow spheres as high-performance anodes for lithium-ion batteries. J Power Sources 324:233–238

Chen S, Shen L, Aken PA, Maier J, Yu Y (2017) Dual-functionalized double carbon shells coated silicon nanoparticles for high performance lithium-ion batteries. Adv Mater 29:1605650–1605657

Kim JM, Guccini V, Seong Kd, Oh J, Alvarez GS, Piao Y (2017) Extensively interconnected silicon nanoparticles via carbon network derived from ultrathin cellulose nanofibers as high performance lithium ion battery anodes. Carbon 118:8–17

Zhang L, Guo H, Rajagopalan R, Hu X, Huang Y, Dou SX, Liu HK (2016) One-step synthesis of a silicon/hematite@carbon hybrid nanosheet/silicon sandwich-like composite as an anode material for Li-ion batteries. J Mater Chem A 4:4056–4061

Jia D, Wang K, Huang J (2017) Filter paper derived nanofibrous silica–carbon composite as anodic material with enhanced lithium storage performance. Chem Eng J 317:673–686

Xie Q, Zheng A, Xie C, Fu W, Wu S, Zhang Y, Zhao P (2016) Graphene functionalized attapulgite/sulfur composite as cathode of lithium–sulfur batteries for energy storage. Microporous Mesoporous Mater 224:239–244

Wang MS, Fan LZ, Huang M, Li J, Qu X (2012) Conversion of diatomite to porous Si/C composites as promising anode materials for lithium-ion batteries. J Power Sources 219:29–35

Yang C, Liu P (2009) Core–shell attapulgite@polypyrrole composite with well-defined corn cob-like morphology via self-assembling and in situ oxidative polymerization. Synth Met 159:2056–2062

Luo H, Chen Y, Mu B, Fu Y, Zhao X, Zhang J (2016) Preparation and electrochemical performance of attapulgite/citric acid template carbon electrode materials. J Appl Electrochem 46:299–307

Luo HM, Yang YF, Sun YX, Zhao X, Zhang JQ (2015) Preparation of lactose-based attapulgite template carbon materials and their electrochemical performance. J Solid State Electrochem 19:1171–1180

Zhu Y, Chen D (2017) Preparation and characterization of attapulgite-based nanofibrous membranes. Mater Des 113:60–67

Fan QH, Shao DD, Hu J, Wu WS, Wang XK (2008) Comparison of Ni2+ sorption to bare and ACT-graft attapulgites: effect of pH, temperature and foreign ions. Surf Sci 602:778–785

Ghorpade RV, Cho DW, Hong SC (2017) Effect of controlled tacticity of polyacrylonitrile (co)polymers on their thermal oxidative stabilization behaviors and the properties of resulting carbon films. Carbon 121:502–511

Yin L, Wang J, Lin F, Yang J, Nuli Y (2012) Polyacrylonitrile/graphene composite as a precursor to a sulfur-based cathode material for high-rate rechargeable Li–S batteries. Energy Environ Sci 5:6966–6972

Arbab S, Zeinolebadi A (2013) A procedure for precise determination of thermal stabilization reactions in carbon fiber precursors. Polym Degrad Stab 98:2537–2545

Nunna S, Creighton C, Fox BL et al (2017) The effect of thermally induced chemical transformations on the structure and properties of carbon fibre precursors. J Mater Chem A 5:7372–7382

Ouyang Q, Cheng L, Wang H, Li K (2008) Mechanism and kinetics of the stabilization reactions of itaconic acid-modified polyacrylonitrile. Polym Degrad Stab 93:1415–1421

Boudriche L, Calvet R, Hamdi B, Balard H (2012) Surface properties evolution of attapulgite by IGC analysis as a function of thermal treatment. Colloids Surf A: Physicochem Eng Asp 399:1–10

Meng J, Cao Y, Suo Y, Liu Y, Zhang J, Zheng X (2015) Facile fabrication of 3D SiO2@graphene aerogel composites as anode material for lithium ion batteries. Electrochim Acta 176:1001–1009

Zhou X, Wu L, Yang J, Tang J, Xi L, Wang B (2016) Synthesis of nano-sized silicon from natural halloysite clay and its high performance as anode for lithium-ion batteries. J Power Sources 324:33–40

Jiao M, Liu K, Shi Z, Wang C (2017) SiO2/carbon composite microspheres with hollow core–shell structure as a high-stability electrode for lithium-ion batteries. ChemElectroChem 4:542–549

Kim JY, Nguyen DT, Kang JS, Song SW (2015) Facile synthesis and stable cycling ability of hollow submicron silicon oxide–carbon composite anode material for Li-ion battery. J Alloy Compd 633:92–96

Wang X, Feng J, Bai Y, Zhang Q, Yin Y (2016) Synthesis, properties, and applications of hollow micro-/nanostructures. Chem Rev 116:10983–11060

Zhu Y, Chen D (2017) Novel clay-based nanofibrous membranes for effective oil/water emulsion separation. Ceram Int 43:9465–9471

Zhang Y, Li K, Ji P, Chen D, Zeng J, Sun Y, Zhang P, Zhao J (2016) Silicon-multi-walled carbon nanotubes-carbon microspherical composite as high-performance anode for lithium-ion batteries. J Mater Sci 52:3630–3641. doi:10.1007/s10853-016-0503-6

Zhang X, Zhu G, Wang M, Li J, Lu T, Pan L (2017) Covalent-organic-frameworks derived N-doped porous carbon materials as anode for superior long-life cycling lithium and sodium ion batteries. Carbon 116:686–694

Su J, Zhao J, Li L, Zhang C, Chen C, Huang T, Yu A (2017) Three-dimensional porous Si and SiO2 with in situ decorated carbon nanotubes as anode materials for li-ion batteries. ACS Appl Mater Interfaces 9:17807–17813

Ren W, Wang Y, Tan Q, Zhong Z, Su F (2016) Novel silicon/carbon nano-branches synthesized by reacting silicon with methyl chloride: a high performing anode material in lithium ion battery. J Power Sources 332:88–95

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lan, Y., Chen, D. Fabrication of nano-sized attapulgite-based aerogels as anode material for lithium ion batteries. J Mater Sci 53, 2054–2064 (2018). https://doi.org/10.1007/s10853-017-1623-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1623-3