Abstract

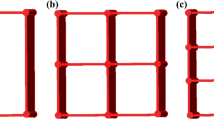

This paper presents an experimental study on the dynamic response of multi-ply woven fabrics subjected to impact by a spherical steel projectile in a velocity regime ranging from 120 to 200 m/s. A plain weave fabric made of Spectra® 1000 fibres was used to fabricate test samples having different numbers of layers and fold patterns. The effect of fabric folding was investigated by comparing the impact performance of samples consisting of separate unfolded fabrics, continuous accordion-fold fabrics, and continuous roll-fold fabrics, respectively. It was found that the perforation resistance and energy absorption capacity were significantly improved by folding a fabric into multiple plies compared to the unfolded counterparts, and the roll-fold fabrics performed best in this study. Fabric folding seemed to have only a negligible effect on the back-face deflections of woven fabrics. The effect of thickness (or the number of layers) on energy absorption efficiency was different among the tested fabrics, due to the different inter-layer interactions depending on fold patterns.

Similar content being viewed by others

References

Jacobs MJN, Van Dingenen JLJ (2001) Ballistic protection mechanisms in personal armour. J Mater Sci 36(13):3137–3142. doi:10.1023/a:1017922000090

David NV, Gao XL, Zheng JQ (2009) Ballistic resistant body armor: contemporary and prospective materials and related protection mechanisms. Appl Mech Rev 62(5):050802. doi:10.1115/1.3124644

Cavallaro PV (2011) Soft body armor: an overview of materials, manufacturing, testing, and ballistic impact dynamics. DTIC Document, Fort Belvoir

Loverro KL, Brown TN, Coyne ME, Schiffman JM (2015) Use of body armor protection with fighting load impacts soldier performance and kinematics. Appl Ergon 46(Part A):168–175. doi:10.1016/j.apergo.2014.07.015

Naik D, Sankaran S, Mobasher B, Rajan SD, Pereira JM (2009) Development of reliable modeling methodologies for fan blade out containment analysis—part I: experimental studies. Int J Impact Eng 36(1):1–11. doi:10.1016/j.ijimpeng.2008.03.007

Stahlecker Z, Mobasher B, Rajan SD, Pereira JM (2009) Development of reliable modeling methodologies for engine fan blade out containment analysis. Part II: finite element analysis. Int J Impact Eng 36(3):447–459. doi:10.1016/j.ijimpeng.2008.08.004

Bansal S, Mobasher B, Rajan SD, Vintilescu I (2009) Development of fabric constitutive behavior for use in modeling engine fan blade-out events. J Aerosp Eng 22(3):249–259. doi:10.1061/(ASCE)0893-1321(2009)22:3(249)

Hazell PJ (2016) Armour: materials, theory, and design. CRC Press, Boca Raton

Hearle JWS (2001) High-performance fibres. Woodhead Publishing, Cambridge

Cunniff PM (1992) An analysis of the system effects in woven fabrics under ballistic impact. Text Res J 62(9):495–509. doi:10.1177/004051759206200902

Cunniff PM (1996) A semiempirical model for the ballistic impact performance of textile-based personnel armor. Text Res J 66(1):45–58. doi:10.1177/004051759606600107

Cunniff PM (1999) Dimensionless parameters for optimization of textile-based body armor systems. In: Proceedings of the 18th international symposium on ballistics, San Antonio, Texas, pp 1303–1310

Cunniff PM (1999) A design tool for the development of fragmentation protective body armor. In: Proceedings of the 18th International Symposium on Ballistics, San Antonio, Texas, pp 1295–1302

Cheeseman BA, Bogetti TA (2003) Ballistic impact into fabric and compliant composite laminates. Compos Struct 61(1–2):161–173. doi:10.1016/S0263-8223(03)00029-1

Tabiei A, Nilakantan G (2008) Ballistic impact of dry woven fabric composites: a review. Appl Mech Rev 61(1):010801. doi:10.1115/1.2821711

Chen X, Zhou Y, Wells G (2014) Numerical and experimental investigations into ballistic performance of hybrid fabric panels. Compos B Eng 58:35–42. doi:10.1016/j.compositesb.2013.10.019

Yang C-C, Ngo T, Tran P (2015) Influences of weaving architectures on the impact resistance of multi-layer fabrics. Mater Des 85:282–295. doi:10.1016/j.matdes.2015.07.014

Nilakantan G, Merrill RL, Keefe M, Gillespie JW Jr, Wetzel ED (2015) Experimental investigation of the role of frictional yarn pull-out and windowing on the probabilistic impact response of Kevlar fabrics. Compos B Eng 68:215–229. doi:10.1016/j.compositesb.2014.08.033

Wang Y, Chen X, Young R, Kinloch I, Wells G (2015) A numerical study of ply orientation on ballistic impact resistance of multi-ply fabric panels. Compos B Eng 68:259–265. doi:10.1016/j.compositesb.2014.08.049

Wang Y, Chen X, Young R, Kinloch I, Garry W (2016) An experimental study of the effect of ply orientation on ballistic impact performance of multi-ply fabric panels. Text Res J 86(1):34–43. doi:10.1177/0040517514566110

Min S, Chu Y, Chen X (2016) Numerical study on mechanisms of angle-plied panels for ballistic protection. Mater Des 90:896–905. doi:10.1016/j.matdes.2015.11.019

Tapie E, Tan ESL, Guo YB, Shim VPW (2017) Effects of pre-tension and impact angle on penetration resistance of woven fabric. Int J Impact Eng 106:171–190. doi:10.1016/j.ijimpeng.2017.03.022

Tan VBC, Lim CT, Cheong CH (2003) Perforation of high-strength fabric by projectiles of different geometry. Int J Impact Eng 28(2):207–222. doi:10.1016/S0734-743X(02)00055-6

Kirkwood JE, Kirkwood KM, Lee YS, Egres RG, Wagner NJ, Wetzel ED (2004) Yarn pull-out as a mechanism for dissipating ballistic impact energy in Kevlar® KM-2 fabric: part II: predicting ballistic performance. Text Res J 74(11):939–948. doi:10.1177/004051750407401101

Ha-Minh C, Imad A, Kanit T, Boussu F (2013) Numerical analysis of a ballistic impact on textile fabric. Int J Mech Sci 69:32–39. doi:10.1016/j.ijmecsci.2013.01.014

Nilakantan G, Nutt S (2014) Effects of clamping design on the ballistic impact response of soft body armor. Compos Struct 108:137–150. doi:10.1016/j.compstruct.2013.09.017

Gawandi A, Thostenson ET, Gilllespie JW (2011) Tow pullout behavior of polymer-coated Kevlar fabric. J Mater Sci 46(1):77–89. doi:10.1007/s10853-010-4819-3

LaBarre ED, Calderon-Colon X, Morris M, Tiffany J, Wetzel E, Merkle A, Trexler M (2015) Effect of a carbon nanotube coating on friction and impact performance of Kevlar. J Mater Sci 50(16):5431–5442. doi:10.1007/s10853-015-9088-8

Bazhenov S (1997) Dissipation of energy by bulletproof aramid fabric. J Mater Sci 32(15):4167–4173. doi:10.1023/A:1018674528993

Kirkwood KM, Kirkwood JE, Lee Young Sil, Egres RG, Wagner NJ, Wetzel ED (2004) Yarn pull-out as a mechanism for dissipating ballistic impact energy in Kevlar® KM-2 fabric: part I: quasi-static characterization of yarn pull-out. Text Res J 74(10):920–928. doi:10.1177/004051750407401012

Zhu D, Soranakom C, Mobasher B, Rajan SD (2011) Experimental study and modeling of single yarn pull-out behavior of Kevlar® 49 fabric. Compos A Appl Sci Manuf 42(7):868–879. doi:10.1016/j.compositesa.2011.03.017

Crouch IG, Arnold L, Pierlot A, Billon H (2017) Fibres, textiles and protective apparel. In: Crouch IG (ed) The science of armour materials. Woodhead Publishing, Melbourne, pp 269–330. doi:10.1016/B978-0-08-100704-4.00006-2

Honeywell (2007) Spectra® fiber product information sheets. Honeywell International Inc., Morristown

Vlasblom MP, Van Dingenen JLJ (2009) The manufacture, properties and applications of high strength, high modulus polyethylene fibers. In: Bunsell AR (ed) Handbook of tensile properties of textile and technical fibres. Woodhead Publishing, Cambridge, pp 437–485. doi:10.1533/9781845696801.2.437

Lee BL, Walsh TF, Won ST, Patts HM, Song JW, Mayer AH (2001) Penetration failure mechanisms of armor-grade fiber composites under impact. J Compos Mater 35(18):1605–1633. doi:10.1106/yrbh-jgt9-u6pt-l555

NIJ Standard–0101.04 (2000) Ballistic resistance of personal body armor. U.S. Department of Justice, Office of Justice Programs, National Institute of Justice, Washington

Cannon L (2001) Behind armour blunt trauma—an emerging problem. J R Army Med Corps 147(1):87–96. doi:10.1136/jramc-147-01-09

Miao M (2016) Dynamic modulus and strain wave velocity in ballistic fibre strands. J Mater Sci 51(12):5939–5947. doi:10.1007/s10853-016-9895-6

Marissen R (2011) Design with ultra strong polyethylene fibers. Mater Sci Appl 2(05):319–330

Shim VPW, Guo YB, Tan VBC (2012) Response of woven and laminated high-strength fabric to oblique impact. Int J Impact Eng 48:87–97. doi:10.1016/j.ijimpeng.2011.06.008

Grujicic M, Bell WC, He T, Cheeseman BA (2008) Development and verification of a meso-scale based dynamic material model for plain-woven single-ply ballistic fabric. J Mater Sci 43(18):6301. doi:10.1007/s10853-008-2893-6

Lim CT, Tan VBC, Cheong CH (2002) Perforation of high-strength double-ply fabric system by varying shaped projectiles. Int J Impact Eng 27(6):577–591. doi:10.1016/S0734-743X(02)00004-0

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare.

Rights and permissions

About this article

Cite this article

Wang, H., Hazell, P.J., Shankar, K. et al. Effects of fabric folding and thickness on the impact behaviour of multi-ply UHMWPE woven fabrics. J Mater Sci 52, 13977–13991 (2017). https://doi.org/10.1007/s10853-017-1482-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1482-y