Abstract

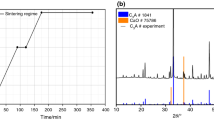

The addition of slightly (CaCO3) and highly soluble (Na2CO3) carbonate salts is expected to favor the formation of carboaluminate phases in hydrated calcium aluminate cements (CACs). A multi-method approach including X-ray diffraction, thermogravimetric analysis, and thermodynamic calculations is applied to highlight that the “conversion phenomena” in CACs cannot be mitigated by the formation of carboaluminate phases (monocarboaluminate: Mc and hemicarboaluminate: Hc) which are anticipated to form following the addition of carbonate salts. Here, carboaluminate phase formation is shown to depend on three factors: (1) water availability, (2) carbonate content of the salts, and their ability to mobilize CO3 2− species in solution, and (3) lime content associated with the carbonate salt. The latter two factors are linked to the composition and solubility of the carbonate agent. It is concluded that limestone (CaCO3), despite being a source of calcium and carbonate species, contributes only slightly to carboaluminate phase formation due to its low solubility and slow dissolution rate. Soluble carbonate salts (Na2CO3) fail to boost carboaluminate phase formation as the availability of Ca2+ ions and water are limiting. Detailed thermodynamic calculations are used to elucidate conditions that affect the formation of carboaluminate phases.

Similar content being viewed by others

Notes

Standard cement chemistry notation is used. As per this simplified notation: C = CaO, A = Al2O3, F = Fe2O3, S = SiO2, CS = CaSO4·2H2O, H = H2O, and \( \overline{\text{C}} = {\text{CO}}_{2} \).

Certain commercial materials and equipment are identified to adequately specify experimental procedures. In no case does, such identification implies recommendation or endorsement by University of California, Los Angeles, École des Mines d’Alès, or Arizona State University, nor does it imply that the items identified are necessarily the best available for the purpose.

References

De Weerdt K, Ben Haha M, Le Saout G et al (2011) Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem Concr Res 41(3):279–291

Damidot D, Glasser FP (1995) Thermodynamic investigation of the CaO—Al2O3—CaSO4—CaCO3-H2O closed system at 25 °C and the influence of Na2O. Adv Cem Res 7(27):129–134

Damidot D, Lothenbach B, Herfort D, Glasser FP (2011) Thermodynamics and cement science. Cem Concr Res 41(7):679–695

Kumar A, Oey T, Kim S, Thomas D, Badran S, Li J, Fernandes F, Neithalath N, Sant G (2013) Simple methods to estimate the influence of limestone fillers on reaction and property evolution in cementitious materials. Cem Concr Compos 42:20–29

Lothenbach B, Winnefeld F (2006) Thermodynamic modelling of the hydration of Portland cement. Cem Concr Res 36(2):209–226

Lothenbach B, Le Saout G, Gallucci E, Scrivener K (2008) Influence of limestone on the hydration of Portland cements. Cem Concr Res 38(6):848–860

Matschei T (2007) Thermodynamics of cement hydration PhD diss., Aberdeen University, Aberdeen

Matschei T, Lothenbach B, Glasser FP (2007) The AFm phase in Portland cement. Cem Concr Res 37(2):118–130

Oey T, Kumar A, Bullard JW, Neithalath N, Sant G (2013) The filler effect: the influence of filler content and surface area on cementitious reaction rates. J Am Ceram Soc 96(6):1978–1990

Tomaž V, Tinta V, Gabrovšek, Kaučič V (2001) The effects of limestone addition, clinker type and fineness on properties of Portland cement. Cem Concr Res 31(1):135–139

Tsivilis S, Chaniotakis E, Kakali G, Batis G (2002) An analysis of the properties of Portland limestone cements and concrete. Cem Concr Compos 24(3):371–378

Puerta-Falla G, Balonis M, Le Saout G, Falzone G, Zhang C, Neithalath N, Sant G (2015) Elucidating the role of the aluminous source on limestone reactivity in cementitious materials. J Am Ceram Soc 98(12):4076–4089

Falzone G, Balonis M, Sant G (2015) X-AFm stabilization as a mechanism of bypassing conversion phenomena in calcium aluminate cements. Cem Concr Res 72:54–68

Lothenbach B, Pelletier-Chaignat L, Winnefeld F (2012) Stability in the system CaO–Al2O3–H2O. Cem Concr Res 42(12):1621–1634

Scrivener KL, Capmas A (1998) Lea’s Chemistry of cement and concrete calcium aluminate cements, Chapter 13, In: Hewlett PC (ed), Wiley, New York

Scrivener KL, Cabiron JL, Letourneux R (1999) High-performance concretes from calcium aluminate cements. Cem Concr Res 29(8):1215–1223

Puerta-Falla G, Kumar A, Gomez-Zamorano L, Bauchy M, Neithalath N, Sant G (2015) The influence of filler type and surface area on the hydration rates of calcium aluminate cement. Constr Build Mater 96:657–665

Klaus SR, Neubauer J, Goetz-Neunhoeffer F (2013) Hydration kinetics of CA2 and CA—investigations performed on a synthetic calcium aluminate cement. Cem Concr Res 43:62–69

Taylor HFW (1997) Cement Chemistry, 2nd edn. Thomas Telford, London

Mangabhai RJ, Glasser FP (2001) Calcium Aluminate Cements. IOM communications, London

Shahwana R, Barnes P, Bensted J, Turrillas X (1994) Conversion of calcium aluminate cement hydrates re-examined with synchrotron energy-dispersive diffraction J Mater Sci lett 13(17):1232–1234

Ukrainczyk N, Šipušić J, Dabić P, Matusinović T (2008) Microcalorimetric study on calcium aluminate cement hydration. 13th International conference on materials, processes, friction and wear, p 382–388

Kuzel HJ (1996) Initial hydration reactions and mechanisms of delayed ettringite formation in Portland cements. Cem Concr Compos 18(3):195–203

Luz AP, Pandolfelli VC (2012) CaCO3 addition effect on the hydration and mechanical strength evolution of calcium aluminate cement for endodontic applications. Ceram Int 38(2):1417–1425

ASTM (International and American Society for Testing & Materials) (2004) Annual book of ASTM standards, American Society for Testing & Materials, USA

National Center for Biotechnology Information (NCBI)—PubChem database. Available at https://www.ncbi.nlm.nih.gov/pccompound. Accessed 10 Dec 2015

FIZ/NIST—Inorganic crystal structure database (ICSD) (version 2009/1). Available for purchase at http://www.nist.gov/srd/nist84.cfm

Mineralogical Society of America—American mineralogist crystal structure database. Available at http://rruff.geo.arizona.edu/AMS/amcsd.php. Accessed 15 Jan 2015

Le Saout G, Kocaba V, Scrivener KL (2011) Application of the Rietveld method to the analysis of anhydrous cement. Cem Concr Res 41:133–148

Kulik D (2013) GEMS-PSI 2.1. Available at http://les.web.psi.ch/Software/GEMS-PSI/. Accessed 18 June 2013

Myers RJ, Lothenbach B, Bernal SA, Provis JL (2015) Thermodynamic modelling of alkali-activated slag cements. Appl Geochem 61:233–247

Martin LHJ, Winnefeld F, Müller CJ, Lothenbach B (2015) Contribution of limestone to the hydration of calcium sulfoaluminate cement. Cem Concr Compos 62:204–211

Thomas JJ, Jennings HM (1998) Free-energy-based model of chemical equilibria in the CaO–SiO2-H2O system. J Am Ceram Soc 81(3):606–612

Paul Scherrer Institute—GEMS: Gibbs free energy software for geochemical modeling. Available at http://gems.web.psi.ch/. Accessed 18 June 2015

Lothenbach B—CEMDATA. Available at http://www.empa.ch/web/s308/cemdata. Accessed 18 June 2014

Haha MB, Lothenbach B, Le Saout G, Winnefeld F (2012) Influence of slag chemistry on the hydration of alkali-activated blast-furnace slag—Part II: effect of Al2O3. Cem Concr Res 42(1):74–83

Pelletier-Chaignat L, Winnefeld F, Lothenbach B, Müller CJ (2012) Beneficial use of limestone filler with calcium sulphoaluminate cement . Constr Build Mater 26(1):619–627

Geoscience for a sustainable earth—Mineral species data base. Available at http://thermoddem.brgm.fr/data/mineraux.php. Accessed on 15 Jan 2015

Önder K, Yaman IO, Tokyay M (2013) Compressive strength development of calcium aluminate cement–GGBFS blends. Cem Concr Compos 35(1):163–170

Lothenbach B, Le Saout G, Gallucci E, Scrivener K (2008) Influence of limestone on the hydration of Portland cements. Cem Concr Res 38(6):848–860

Johnson DR, Robb WA (1973) Gaylussite: thermal properties by simultaneous thermal analysis. Am Mineral 58:778–784

Hartmant M, Trnka O, Vesely V, Karel Svodoba (2001) Thermal dehydration of the sodium carbonate hydrates. Chem Eng Commun 185(1):1–16

Steudel A, Mehl D, Emmerich K (2013) Simultaneous thermal analysis of different bentonite–sodium carbonate systems: an attempt to distinguish alkali-activated bentonites from raw materials. Clay Miner 48(1):117–128

Matschei T, Lothenbach B, Glasser FP (2007) The role of calcium carbonate in cement hydration. Cem Concr Res 37(4):551–558

Baquerizo LG, Matschei T, Scrivener KL, Saeidpour M, Wadsö L (2015) Hydration states of AFm cement phases. Cem Concr Res 73:143–157

Baquerizo LG (2015) Impact of water activity on the mineralogy of hydrated cement Ph.D. diss. École Polytechnique Fédérale de Lausanne, Lausanne

Acknowledgements

The authors acknowledge the financial support for this research provisioned by the University of California, Los Angeles (UCLA), and National Science Foundation (CMMI: 1066583). The authors also acknowledge the provision of materials by OMYA A.G. and Kerneos Aluminate Technologies. The contents of this paper reflect the views and opinions of the authors who are responsible for the accuracy of the datasets presented herein. This research was conducted in the Laboratory for the Chemistry of Construction Materials (LC2) and Molecular Instrumentation Center (MIC) at the University of California, Los Angeles (UCLA). As such, the authors gratefully acknowledge support that has made these laboratories and their operations possible.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Puerta-Falla, G., Balonis, M., Le Saout, G. et al. The influence of slightly and highly soluble carbonate salts on phase relations in hydrated calcium aluminate cements. J Mater Sci 51, 6062–6074 (2016). https://doi.org/10.1007/s10853-016-9912-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-9912-9