Abstract

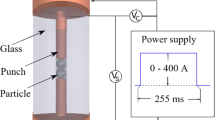

The initial stage of contact formation during field-activated/assisted sintering of powders is investigated experimentally and numerically for spherical particles of nickel, steel, and copper. The results of experimental studies of the contact resistance and the neck formation process due to melting/sintering in two- to three-particle systems under a single high-current pulse from a capacitor discharge are compared with results of fully coupled thermo-electrical finite-element simulations. The impact of particle size, contact geometry, and electrical load on the temperature and temperature gradient distribution during the pulse discharge is analyzed numerically for nickel spheres. The influence of the material itself is compared for nickel, steel, and copper systems.

Similar content being viewed by others

References

Munir ZA, Anselmi-Tamburini U, Ohyanagi M (2006) The effect of electric field and pressure on the synthesis and consolidation of materials: a review of the spark plasma sintering method. J Mater Sci 41:763–772. doi:10.1007/s10853-006-6555-2

Orru R, Licheri R, Locci AM, Cincotti A, Cao G (2009) Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater Sci Eng R 63:127–287

Munir ZA, Quach DV (2011) Electric current activation of sintering: a review of the pulsed electric current sintering process. J Am Ceram Soc 94:1–19

Garay J (2010) Current-activated, pressure-assisted densification of materials. Annu Rev Mater Res 40:445–468

Guillon O, Gonzalez J, Dargatz B, Kessel T, Schierning G, Räthel J, Herrmann M (2014) Field-assisted sintering technology/spark plasma sintering: mechanisms, materials, and technology developments. Adv Eng Mater 16:830–849

Yue M, Zhang J, Xiao Y, Wang G, Li T (2003) New kind of NdFeB magnet prepared by spark plasma sintering. IEEE Trans Magn 39:3551–3553

Gubicza J, Bui HQ, Fellah F, Dirras GF (2009) Microstructure and mechanical behavior of ultrafine-grained Ni processed by different powder metallurgy methods. J Mater Res 24:217–226

Naimi F, Minier L, Le Gallet S, Couque H, Bernard F (2013) Dense nanostructured nickel produced by SPS from mechanically activated powders: enhancement of mechanical properties. J Nanomater 2013:674843

Ning H, Mastrorillo GD, Grasso S, Du B, Mori T, Hu C, Ya Xu, Simpson K, Maizza G, Reece MJ (2015) Enhanced thermoelectric performance of porous magnesium tin silicide prepared using pressure-less spark plasma sintering. J Mater Chem 33:17426–17432

Chen W, Anselmi-Tamburini U, Garay JE, Groza JR, Munir ZA (2005) Fundamental investigations on the spark plasma sintering/synthesis process: I. Effect of dc pulsing on reactivity. Mater Sci Eng A 394:132–138

Anselmi-Tamburini U, Gennari S, Garay JE, Munir ZA (2005) Fundamental investigations on the spark plasma sintering/synthesis process II. Modeling of current and temperature distributions. Mater Sci Eng A 394:139–148

Anselmi-Tamburini U, Garay JE, Munir ZA (2005) Fundamental investigations on the spark plasma sintering/synthesis process III. Current effect on reactivity. Mater Sci Eng A 407:24–30

Frei JM, Anselmi-Tamburini U, Munir ZA (2007) Current effects on neck growth in the sintering of copper spheres to copper plates by the pulsed electric current method. J Appl Phys 101:114914

Toyofuku N, Kuramoto T, Imai T, Ohyanagi M, Munir ZA (2012) Effect of pulsed DC current on neck growth between tungsten wires and tungsten plates during the initial stage of sintering by the spark plasma sintering method. J Mater Sci 47:2201–2205. doi:10.1007/s10853-011-6026-2

Li W, Olevsky EA, McKittrick J, Maximenko AL, German RM (2012) Densification mechanisms of spark plasma sintering: multi-step pressure dilatometry. J Mater Sci 47:7036. doi:10.1007/s10853-012-6515-y

Demirskyi D, Borodianska H, Agrawal D, Ragulya A, Sakka Y, Vasylkiv O (2012) Peculiarities of the neck growth process during initial stage of spark-plasma, microwave and conventional sintering of WC spheres. J Alloys Compd 523:1–10

Yanagisawa O, Kuramoto H, Matsugi K, Komatsu M (2003) Observation of particle behavior in copper powder compact during pulsed electric discharge. Mat Sci Eng A 350:184–189

Song X, Liu X, Zhang J (2006) Neck formation and self-adjusting mechanism of neck growth of conducting powders in spark plasma sintering. J Am Ceram Soc 89:494–500

Hulbert DM, Anders A, Dudina DV, Andersson J, Jiang D, Unuvar C, Anselmi-Tamburini U, Enrique L, Mukherjee AK (2008) The absence of plasma in spark plasma sintering. J Appl Phys 104:033305-1–033305-7

Saunders T, Grasso S, Reecea MJ (2014) Plasma formation during electric discharge (50 V) through conductive powder compacts. J Eur Ceram Soc 35:871–877

Trapp J, Kieback B (2015) Temperature distribution in metallic powder particles during initial stage of field-activated sintering. J Am Ceram Soc 98:3547–3552

Kuz’mov AV, Olevskii EA, Aleksandrova EV (2013) Effect of micrononuniform heating of powder in field-assisted sintering on shrinkage kinetics. Powder Metall Met Ceram 51:657–665

Holland TB, Anselmi-Tamburini U, Quach DV, Tran TB, Mukherjee AK (2012) Effects of local Joule heating during the field assisted sintering of ionic ceramics. J Eur Ceram Soc 32:3667–3674

Vanmeensel K, Laptev A, Hennicke J, Vleugels J, Van Der Biest O (2005) Modelling of the temperature distribution during field assisted sintering. Acta Mater 53:4379–4388

Zavaliangos A, Zhang J, Krammer M, Groza JR (2004) Temperature evolution during field activated sintering. Mater Sci Eng A 379:218–228

Pavia A, Durand L, Ajustron F, Bley V, Chevallier G, Peigney A, Estournes C (2013) Electro-thermal measurements and finite element method simulations of a spark plasma sintering device. J Mater Process Technol 213:1327–1336

Allen J, Walter C (2012) Numerical simulation of the temperature and stress field evolution applied to the field assisted sintering technique. ISRN Mater Sci 1–9

Wang C, Cheng L, Zhao Z (2010) FEM analysis of the temperature and stress distribution in spark plasma sintering: modelling and experimental validation. Comput Mater Sci 49:351–362

Wolff C, Mercier S, Couque H, Molinari A (2012) Modeling of conventional hot compaction and spark plasma sintering based on modified micromechanical models of porous materials. Mech Mater 49:72–91

Cincotti A, Locci AM, Orru R, Cao G (2007) Modeling of SPS apparatus: temperature, current and strain distribution with no powders. AIChE J 53:703–719

Olevsky EA, Garcia-Cardona C, Bradbury WL, Haines CD, Martin DG, Kapoor D (2012) Fundamental aspects of spark plasma sintering: II. Finite element analysis of scalability. J Am Ceram Soc 95:2414–2422

Falcon E, Castaing B (2005) Electrical conductivity in granular media and Branly’s coherer: a simple experiment. Am J Phys 73(4):302–307

Zinoviev VE (1989) Thermo-physical properties of materials at high temperatures, metallurgy. Atomnaya Energia, Moscow

Ho CY, Chu TK (1977) Electrical resistivity and thermal conductivity of nine selected AISI stainless steels, CINDAS report 45

Ansys 15.0 Documentation (2014) SAS IP, Inc

Braunovic M, Myshkin NK, Konchits VV (2007) Electrical contacts: fundamentals, applications and technology, 2nd edn. Taylor & Francis Group, Boca Raton

Acknowledgements

This work has been supported by the German Research Foundation (DFG) under the Grants KI506/20-1 and WA2323/10-1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Semenov, A.S., Trapp, J., Nöthe, M. et al. Experimental and numerical analysis of the initial stage of field-assisted sintering of metals. J Mater Sci 52, 1486–1500 (2017). https://doi.org/10.1007/s10853-016-0444-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0444-0