Abstract

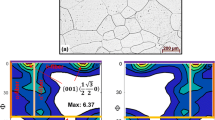

Twin-roll casting was adopted to fabricate a 2.7-mm-thick material of the non-oriented 6.5 wt% Si electrical steel, which was then hot rolled, warm rolled, and annealed. A detailed study of the microstructural and textural evolutions in the whole processing route was conducted by optical microscopy, X-ray diffraction, and electron backscattered diffraction. Beneficial λ-fiber texture, strong \( \left\{ {114} \right\} \langle 4\overline{8} 1\rangle, \) and Goss textures dominated the annealing texture. Special attention was focused on the origin and evolution of the \( \left\{ {114} \right\} \langle 4\overline{8} 1\rangle \) texture during the annealing process. The results showed that the nucleation sites of the \( \left\{ {114} \right\} \langle 4\overline{8} 1\rangle \) nuclei were not only confined to deformation bands of the deformed \( \left\{ {001} \right\} \langle 1\overline{1} 0\rangle \) grain but also widely distributed in many other deformation heterogeneities of the warm-rolled sheet. The high similarities demonstrated by the nucleation and recrystallization textures, and the gradually intensified \( \left\{ {114} \right\} \langle 4\overline{8} 1\rangle \) recrystallization texture indicated the combined operations of the oriented nucleation and oriented growth mechanisms during the evolution of the \( \left\{ {114} \right\} \langle 4\overline{8} 1\rangle \) recrystallization texture. After recrystallization, some \( \left\{ {114} \right\} \langle 4\overline{8} 1\rangle \) grains which already acquired the advantage in grain size over those clustered \( \left\{ {111} \right\} \langle 1\overline{2} 1\rangle \) grains due to the orientation pinning effect tended to gain further growth during the grain growing stage, resulting in the prevalence of the \( \left\{ {114} \right\} \langle 4\overline{8} 1\rangle \) annealing texture.

Similar content being viewed by others

References

Arai KI, Ishiyama K (1994) Recent developments of new soft magnetic materials. J Magn Magn Mater 133:233–237

Yu JH, Shin JS, Bae JS, Lee ZH, Lee TD, Lee HM, Lavernia EJ (2001) The effect of heat treatments and Si contents on B2 ordering reaction in high-silicon steels. Mater Sci Eng A 307:29–34

Li HZ, Liu ZY (2015) Tensile properties of strip casting 6.5 wt% Si steel at elevated temperatures. Mater Sci Eng 639:412–416

Li HZ, Liu HT, Wang Xl, Cao GM, Li CG, Liu ZY, Wang GD (2016) Effect of cerium on the as-cast microstructure and tensile ductility of the twin-roll casting Fe-6.5 wt% Si alloy. Mater Lett 165:5–8

Li HZ, Liu HT, Liu ZY, Lu HH, Song HY, Wang GD (2014) Characterization of microstructure, texture and magnetic properties in twin-roll casting high silicon non-oriented electrical steel. Mater Charact 88:1–6

Li HZ, Liu HT, Liu Y, Liu ZY, Cao GM, Luo ZY, Zhang FQ, Chen SL, Lyu L, Wang GD (2014) Effects of warm temper rolling on microstructure, texture and magnetic properties of strip-casting 6.5 wt% Si electrical steel. J Magn Magn Mater 370:6–12

Li HZ, Liu HT, Liu ZY, Wang GD (2015) Microstructure, texture evolution and magnetic properties of strip-casting non-oriented 6.5 wt% Si electrical steel doped with cerium. Mater Charact 103:101–106

Dillamore IL, Katoh H, Haslam K (1974) The nucleation of recrystallization and the development of textures in heavily compressed iron-carbon alloys. Texture 1:151–156

Verbeken K, Kestens L, Jonas JJ (2003) Microtextural study of orientation change during nucleation and growth in a cold rolled ULC steel. Scripta Mater 48(10):1457–1462

Gobernado P, Petrov R, Ruiz D, Leunis E, Kestens LAI (2010) Texture evolution in Si-alloyed ultra low-carbon steels after severe plastic deformation. Adv Eng Mater 12:1077–1081

Homma H, Nakamura S, Yoshinaga N (2004) On {h,1,1} < 1/h,1,2 > the recrystallization texture of heavily cold rolled BCC steel. Mater Sci Forum 467–470:269–274

Quadir MZ, Duggan BJ (2004) Deformation banding and recrystallization of α fiber components in heavily rolled IF steel. Acta Mater 52:4011–4021

Liu GL, Duggan BJ (2001) Deformation banding and ferrite-type rolling textures. Metall Mater Trans A 32A:125–134

Gobernado P, Petrov RH, Kestens LAI (2012) Recrystallized {311} < 136 > orientation in ferrite steels. Scripta Mater 66:623–626

Gobernado P, Petrov RH, Moerman J, Barbatti C, Kestens L (2012) Origin of the {h11} < 1/h,1,2 > fiber in single phase ferrite steels. Mater Sci Forum 715–716:134–139

Kestens L, Jacobs S (2008) Texture control during the manufacturing of nonoriented electrical steels. Texture stress Microstruct 2008:1–9

Sidor JJ, Verbeken K, Gomes E, Schneider J, Calvillo PR, Kestens LAI (2012) Through process texture evolution and magnetic properties of high Si non-oriented electrical steels. Mater Charact 71:49–57

Takatani H, Gandin ChA, Rappaz M (2000) EBSD characterization and modeling of columnar dendritic grains growing in the presence of fluid flow. Acta Mater 48:675–688

Luiten EEM, Blok K (2003) Stimulating R&D of industrial energy-efficient technology; the effect of government intervention on the development of strip casting technology. Energy Policy 31:1339–1356

Humphreys FJ, Hatherly M (2004) Recrystallizaiton and related annealing phenomena, 2nd edn. Elsevier, Oxford

Inagaki H (1994) Fundamental aspect of texture formation in low carbon steel. ISIJ Int 34(4):313–321

Barnett MR, Jonas JJ (1997) Influence of ferrite rolling temperature on grain size and texture in annealed low C and IF steels. ISIJ Int 37(7):706–714

Senuma T, Yada H, Shimizu R, Harase J (1990) Textures of low carbon and titanium bearing extra low carbon steel sheets hot rolled below AR3 temperatures. Acta Metall Mater 38(12):2673–2681

Barnett MR (1998) Role of in-grain shear bands in the nucleation of < 111 >//ND recrystallization textures in warm rolled steel. ISIJ Int 38(1):78–85

Homma H, Hutchinson B (2003) Orientation dependence of secondary recrystallization in silicon-iron. Acta Mater 51:3795–3805

Acknowledgements

This work was supported by the National High Technology R&D “863” Program (Grant no. 2012AA03A506).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, HZ., Liu, ZY., Wang, XL. et al. \( \left\{ {114} \right\} \langle 4\overline{8} 1\rangle \) Annealing texture in twin-roll casting non-oriented 6.5 wt% Si electrical steel. J Mater Sci 52, 247–259 (2017). https://doi.org/10.1007/s10853-016-0327-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0327-4