Abstract

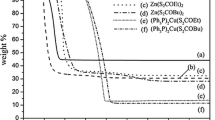

Both experimental measurements and assessment of phase equilibria are reported in the Cu–Ga–In material system, which is an important constituent in growth of the thin film photovoltaic absorber Cu(In,Ga)Se2 (CIGS). Characterization of four different alloys using inductively coupled plasma atomic emission spectroscopy, X-ray diffraction, scanning electron microscopy, energy dispersive spectroscopy, differential thermal analysis, and differential scanning calorimetry has been conducted, and high-temperature equilibration studies have been performed on 2 of those. The new data are qualitatively consistent with the previous nonequilibrium thin film Cu–Ga–In observations. A thermodynamic assessment of the ternary system has also been performed using a CALPHAD approach after re-assessing the Cu–In constituent. The model fits the ternary data well in addition to the Cu–Ga, Cu–In, and Ga–In binary data. Practical applications of the model to metal precursors in a CIGS selenization process are discussed. Using the assessed parameters, the model predicts that at temperatures typically used in CIGS processes, Cu–Ga–In films should undergo equilibrium phase transformations. Slight changes in composition are found to determine whether or not these transitions occur, and at what temperature. Equilibrated precursor films are calculated to have high γ-Cu9(Ga,In)4 phase content, where reducing equilibration and γ-Cu9(Ga,In)4 formation have previously been found to improve photovoltaic performance.

Similar content being viewed by others

References

Chen G, Ma J, Geng Z (2005) Fabrication and properties of lead-free Sn–Ag–Cu–Ga solder alloy. Mater Sci Forum 475–479:1747–1750. doi:10.4028/http://www.scientific.net/MSF.475-479.1747

Gierlotka W (2012) Thermodynamic description of the quaternary Ag–Cu–In–Sn system. J Electron Mater 41:86–108. doi:10.1007/s11664-011-1757-z

Jackson P, Hariskos D, Wuerz R et al (2015) Properties of Cu(In,Ga)Se2 solar cells with new record efficiencies up to 21.7%. Phys Status Solidi (RRL) Rapid Res Lett 9:28–31. doi:10.1002/pssr.201409520

Kim K, Hanket GM, Huynh T, Shafarman WN (2012) Three-step H2Se/Ar/H2S reaction of Cu–In–Ga precursors for controlled composition and adhesion of Cu(In, Ga)(Se, S)2 thin films. J Appl Phys 111:83710

Anderson TJ, Ansara I (1991) The Ga-In (gallium-indium) system. J Phase Equilib 12:64–72

Andrews KW, Hume-Rothery W (1941) On the a/b brass type of equilibrium. Proc Royal Soc Lond Ser A 178:464–473

Bahari Z, Dichi E, Legendre B (1999) Heat content and heat capacity of Cu0.7In0.3 from 298 to 1273 K. Z Metallkd 90:55–59

Bahari Z, Dichi E, Legendre B, Dugué J (2003) The equilibrium phase diagram of the copper–indium system: a new investigation. Thermochim Acta 401:131–138

Bhattacharya D, Masson B (1974) Thermodynamic properties of a Cu–In alloys by the method of atomic absorption. Metall Trans 5:1357–1361

Bolcavage A, Chen SW, Kao CR, Chang YA, Romig AD (1993) Phase equilibria of the Cu–In system I: Experimental investigation. J Phase Equilib 14:14–21. doi:10.1007/bf02652157

Cao S, Huang S, Chu M, Yue Q, Shen J (2007) Thermodynamic optimization of Cu–In system. Xiyou Jinshu 31:807

Chatterjee SC, Gupta MP (1975) Lattice parameters of some binary and ternary copper alloys. J Appl Crystallogr 8:492–493

Che GC, Ellner M (1992) Powder crystal data for the high-temperature phases Cu4In, Cu9In4(h) and Cu2In(h). Powder Diffr 7:107–108

Chen JS, Kolawa E, Nicolet MA, Ruiz RP (1991) Cu/In deposited at room temperature: morphology, phases and reactions. Solar Cells 30:451–458

Corderoy DJH, Honeycombe RWK (1963–1964) Age-hardening in copper-base indium alloys. J Inst Met 92: 65–69

De M (1969) Thermal expansion of some Cu- and Ag-base alloys. Indian J Phys 43:367–376

Dichi E, Legendre B (2000) Enthalpy of formation of Cu0.70In0.30 and Cu0.64In0.36 phases by solution calorimetry. Z Metallkd 91:47–50

Elding-Pontén M, Stenberg L, Lidin S (1997) The h-phase field of the Cu–In system. J Alloys Compd 261:162–171

Fournelle RA, Clark JB (1972) The genesis of the cellular precipitation reaction. Metall Trans 3:2757–2767

Hertz J, El Aissaoui K, Bouirden L (2002) A thermodynamic optimization of the Cu–In system. J Phase Equilib 23:473–479

Hume-Rothery W, Raynor GV, Reynolds PW, Packer HK (1940) The constitution and structure of alloys of intermediate composition in the systems copper–indium, copper–aluminum, copper–germanium, silver–aluminum, and silver–germanium. J Inst Met 66:209–239

Jacob KT, Alcock CB (1973) Activity of indium in a-solid solutions of Cu + In, Au + In and Cu + Au + In alloys. Acta Metall 21:1011–1016

Jain KC, Ellner M, Schubert K (1972) Über die Phasen in der Nähe der Zusammensetzung Cu64In36. Zeitschrift für Metallkunde 63:456–461

Jones RO, Owen EA (1953–1954) X-ray determination of the alpha-phase boundary of the copper–indium alloy system. J Inst Met 82:445–448

Kang T, Castanet R (1977) Étude thermodynamique du systéme binaire cuivre-indium I. Étude calorimétrique. J Less Common Met 51(1):125–135

Kang T, Kehiaian HV, Castanet R (1976) Étude thermodynamique du systéme binaire cuivre-indium I. Étude calorimétrique. J Calorim Anal Therm 7:1

Kao CR, Bolcavage A, Chen S-L, Chen SW, Chang YA, Romig AD (1993) Phase equilibria of the Cu–In system II: thermodynamic assessment and calculation of phase diagram. J Phase Equilib 14:22–30. doi:10.1007/bf02652158

Keppner W, Klas T, Körner W, Wesche R, Schatz G (1985) Compound formation at Cu–In thin-film interfaces detected by perturbed g-g angular correlations. Phys Rev Lett 54:2371

Kirchner HOK, Mellor BG, Chadwick GA (1978) A calorimetric determination of the interfacial enthalpy of Cu–In and Cu–Al lamellar eutectoids. Acta Metall 26:1023–1031

Kleppa OJ (1956) Heat of formation of solid and liquid binary alloys of copper with cadmium, indium, tin and antimony at 450°. J Phys Chem 60:852–858. doi:10.1021/j150541a005

Knott S, Mikula A (2006) Calorimetric investigation of the binary Cu–In system. Int J Mater Res 97:1098–1101

Koster AS, Wolff LR, Visser GJ (1980) Structure of copper–indium Cu7In3. Acta Crystallogr Sect B 36:3094–3096. doi:10.1107/s0567740880010886

Kutsenok IB, Geiderikh VA, Gerasimov YI, Yalkanen KK (1983) Study of the thermodynamic properties of indium–copper alloys by an instantaneous EMF recording method. Russ J Phys Chem 57:1639–1641

Li J-B, Ji L, Liang JK et al (2008) A thermodynamic assessment of the copper–gallium system. Calphad 32:447–453. doi:10.1016/j.calphad.2008.03.006

Lidin S, Larsson A-K (1995) A survey of superstructures in intermetallic NiAs-Ni2In-type phases. J Solid State Chem 118:313–322

Lidin S, Stenberg L, Elding-Pontén M (1997) The B8 type structure of Cu7In3. J Alloys Compd 255:221–226

Liu HS, Liu XJ, Cui Y et al (2002) Thermodynamic assessment of the Cu–In binary system. J Phase Equilib 23:409–415

Liu X, Liu H, Ohnuma I et al (2001) Experimental determination and thermodynamic calculation of the phase equilibria in the Cu–In–Sn system. J Electron Mater 30:1093–1103

Masson DB, Bhattacharya D (1975) The effect of excess entropy on the activity coefficient of indium in a Cu–In alloys. Scripta Metall 9:207–210

Mizutani U, Noritake T, Ohsuna T, Takeuchi T (2010) Hume-Rothery electron concentration rule across a whole solid solution range in a series of gamma-brasses in Cu–Zn, Cu–Cd, Cu–Al, Cu–Ga, Ni–Zn and Co–Zn alloy systems. Philos Mag 90:1985–2008. doi:10.1080/14786430903246320

Muschik T, Hehenkamp T (1987) Fest-flüssig-Gleichgewichte auf der Cu-Seite des Systems Cu–In. Metallkd 78:358–361

Orbey N, Birkmire R, Russell T, Jones G (2000) Copper–indium alloy transformations. J Phase Equilib 21:509–513. doi:10.1007/s11669-000-0018-2

Owen EA, Morris DP (1949–1950) The application of X-ray methods to the determination of phase boundaries in metallurgical equilibrium diagrams. J Inst Met 76(2):145–168

Owen EA, O’Donnell Roberts EA (1952–1953) The solubility of indium in copper. J Inst Met 81:479–480

Owen EA, Roberts EW (1939) XXIX Factors affecting the limit of solubility of elements in copper and silver. Philos Mag Ser 7 27:294–327. doi:10.1080/14786443908562230

Piao S, Lidin S (2008) A new compound in the Cu–In system—the synthesis and structure of Cu10In7. Zeitschrift für anorganische und allgemeine Chemie 634:2589–2593. doi:10.1002/zaac.200800275

Rajasekharan TP, Schubert K (1981) Kristallstruktur von Cu11In9. Z Metallkd 72:275–278

Ramos de Debiaggi S, Cabeza GF, Toro CD, Monti AM, Sommadossi S, Guillermet AF (2011) Ab initio study of the structural, thermodynamic and electronic properties of the Cu10In7 intermetallic phase. J Alloys Compd 509:3238–3245

Ramos de Debiaggi S, Deluque Toro C, Cabeza GF, Fernández Guillermet A (2012) Ab initio comparative study of the Cu–In and Cu–Sn intermetallic phases in Cu–In–Sn alloys. J Alloys Compd 542:280–292

Reddy SR, Hajra JP (1993) Thermodynamics and phase equilibria in the system Ga-In using multi-parameter functions. Calphad 17:151–156

Reynolds J, Wiseman WA, Hume-Rothery W (1951–1952) The equilibrium diagram of the system copper–indium in the region 25–35 at.% indium. J Inst Met 80:637–640

Stirling PH, Raynor GV (1955–1956) The copper-rich alloys of the system copper–aluminum–indium. J Inst Met 84:57–65

Straumanis ME, Yu LS (1969) Lattice parameters, densities, expansion coefficients and perfection of structure of Cu and of Cu–In a phase. Acta Crystallogr A 25:676–682

Subramanian PR, Laughlin DE (1989) The Cu–In (Copper–Indium) system. J Phase Equilib 10:554–568. doi:10.1007/bf02882415

Vinokurova GA, Geiderikh VA (1976) Thermodynamic properties of indium–copper alloys. Russ J Phys Chem 50:1661

Wallbrecht PC, Blachnik R, Mills KC (1981) The heat capacity and enthalpy of some hume-rothery phases formed by copper, silver and gold. Part III. Cu + Ga, Ag + Ga, Au + Ga, Cu + In, Ag + In and Au + In systems. Thermochim Acta 48:69–82

Weibke F, Eggers H (1934) Das Zustandsdiagramm des Systems Kupfer-Indium. Zeitschrift für anorganische und allgemeine Chemie 220:273–292

Hanket GM, Shafarman WN, McCandless BE, Birkmire RW (2007) Incongruent reaction of Cu–(InGa) intermetallic precursors in H2Se and H2S. J Appl Phys 102(07):4922

Kim WK, Shen J, Chu M, Jung JH, Anderson TJ (2012) Prediction of the Cu–Ga–In ternary phase diagram. J Nanoelectron Optoelectron 7:425–429

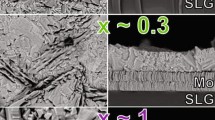

Purwins M, Enderle R, Schmid M et al (2007) Phase relations in the ternary Cu–Ga–In system. Thin Solid Films 515:5895–5898

Dinsdale AT (1991) SGTE data for pure elements. Calphad 15:317–425

Schmid-Fetzer R, Andersson D, Chevalier PY et al (2007) Assessment techniques, database design and software facilities for thermodynamics and diffusion. Calphad 31:38–52. doi:10.1016/j.calphad.2006.02.007

Lukas HL, Fries SG, Sundman B (2007) Computational thermodynamics—the calphad method. Cambridge University Press, Cambridge

Hillert M, Jansson B, Sundman B, Ågren J (1985) A two-sublattice model for molten solutions with different tendency for ionization. Metall Mater Trans A 16:261–266. doi:10.1007/bf02815307

Redlich O, Kister AT (1948) Algebraic representation of thermodynamic properties and the classification of solutions. Ind Eng Chem 40:345–348

Brummer A, Honkimäki V, Berwian P, Probst V, Palm J, Hock R (2003) Formation of CuInSe2 by the annealing of stacked elemental layers–analysis by in situ high-energy powder diffraction. Thin Solid Films 437:297–307

Gupta A, Isomura S (1998) Precursor modification for preparation of CIS films by selenization technique. Solar Energy Mater Solar Cells 53:385–401

Gupta A, Shirakata S, Isomura S (1994) Studies on CuIn precursor for the preparation of CuInSe2 thin films by the selenization technique. Solar Energy Mater Solar Cells 32:137–149

Prepelita P, Medianu R, Iacomi F, Sandu I (2011) Physico-chemical properties of CuInGa-ZnS heterostructure deposited. Rev Chim 62:905–907

Alberts V (2007) A comparison of the material and device properties of homogeneous and compositional-graded Cu(In, Ga)(Se, S)2 chalcopyrite thin films. Semicond Sci Technol 22:585

Hanket GM, Kamada R, Kim WK, Shafarman WN (2008) Effect of reaction temperature on Cu(InGa)(SeS)2 formation by a sequential H2Se/H2S precursor reaction process. Photovoltaic Specialists Conference (PVSC), 33rd IEEE: 1. Doi:10.1109/pvsc.2008.4922470

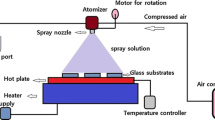

Huynh T, Buchanan W, Kim K, McCandless B, Shafarman W, Birkmire R (2011) Cu–In–Ga metal precursors sputter deposited from a single ternary target for Cu(lnGa)(SeS)2 film formation. Photovoltaic Specialists Conference (PVSC), 37th IEEE: 382. Doi:10.1109/pvsc.2011.6185974

Krishnan R (2012) Rapid routes for synthesis of CIGS absorbers. Dissertation, University of Florida

Chen GS, Yang JC, Chan YC, Yang LC, Huang W (2009) Another route to fabricate single-phase chalcogenides by post-selenization of Cu–In–Ga precursors sputter deposited from a single ternary target. Solar Energy Mater Solar Cells 93:1351–1355

Haug V, Klugius I, Friedlmeier TM, Quintilla A, Ahlswede E (2011) Cu(In, Ga)Se2 thin-film solar cells based on a simple sputtered alloy precursor and a low-cost selenization step. J Photon Energy 1:018002

Su C-Y, Ho W-H, Lin H-C, Nieh C-Y, Liang S-C (2011) The effects of the morphology on the CIGS thin films prepared by CuInGa single precursor. Solar Energy Mater Solar Cells 95:261–263

Song HK, Jeong JK, Kim HJ, Kim SK, Yoon KH (2003) Fabrication of CuIn1−xGaxSe2 thin film solar cells by sputtering and selenization process. Thin Solid Films 435:186–192

Keene BJ (1993) Review of data for the surface tension of pure metals. Int Mater Rev 38:157–192

Muzzillo CP, Mansfield LM, DeHart C, et al (2015) Differences between CuGa/In and Cu/Ga/In films for selenization. Photovoltaic Specialist Conference (PVSC), 2015 IEEE 42nd: in press

Muzzillo CP, Mansfield LM, Dehart C, et al (2014) The effect of Ga content on the selenization of co-evaporated CuGa/In films and their photovoltaic performance. Photovoltaic Specialist Conference (PVSC), 2014 IEEE 40th: 1649. Doi:10.1109/PVSC.2014.6925236

Mainz R, Weber A, Rodriguez-Alvarez H, et al (2014) Time-resolved investigation of Cu(In,Ga)Se2 growth and Ga gradient formation during fast selenisation of metallic precursors. Progress in Photovoltaics: Research and Applications in press. Doi:10.1002/pip.2531

Kim WK, Hanket GM, Shafarman WN (2011) Ga homogenization by simultaneous H2Se/H2S reaction of Cu–Ga–In precursor. Solar Energy Mater Solar Cells 95:235–238

Kushiya K, Shimizu A, Yamada A, Konagai M (1995) Development of high-efficiency CuInxGa1−xSe2 thin-film solar cells by selenization with elemental Se vapor in vacuum. Jpn J Appl Phys 34:54–60

Klenk M, Schenker O, Alberts V, Bucher E (2001) Control of two-step growth processes of chalcopyrite thin films by X-ray fluorescence spectroscopy. Appl Surf Sci 173:62. doi:10.1016/S0169-4332(00)00876-X

Berger LI, Strel’chenko SS, Bondar SA, Molodyk AD, Balanevskaya AE, Levedev VV (1969) дaвлeниe диccoциaции двoйныx пoлyпpoвoдникoвыx coeдинeний типa BIII2CVI3. Izvestiya Akademii nauk SSSR. Neorg Mater 5:872

Brebrick RF, Su C-H (2002) Partial pressures for several In-Se compositions from optical absorbance of the vapor. J Phase Equilib 23:397–408. doi:10.1361/105497102770331343

Colin R, Drowart J (1968) Mass spectrometric determination of dissociation energies of gaseous indium sulphides, selenides and tellurides. Trans Faraday Soc 64:2611–2621. doi:10.1039/tf9686402611

Greenberg JH, Borjakova VA, Shevelkov VF (1973) Thermodynamic properties of In2Se. J Chem Thermodyn 5:233–237. doi:10.1016/S0021-9614(73)80083-7

Piacente V, Bardi G, Di Paolo V, Ferro D (1976) The vapour pressure over Ga2S2 and Ga2Se2. J Chem Thermodyn 8:391–401. doi:10.1016/0021-9614(76)90080-X

Acknowledgements

The authors gratefully acknowledge funding from the U.S. Department of Energy under FPACE contract DE-EE0005407. The authors would like to thank GE for graciously providing bulk alloys and performing DSC, and Thermo-Calc Software and CompuTherm LLC for providing software. This study was funded by Department of Energy FPACE grant DE-EE0005407.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Muzzillo, C.P., Campbell, C.E. & Anderson, T.J. Cu–Ga–In thermodynamics: experimental study, modeling, and implications for photovoltaics. J Mater Sci 51, 3362–3379 (2016). https://doi.org/10.1007/s10853-015-9651-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9651-3