Abstract

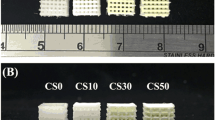

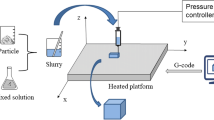

In this study, we explored the feasibility of fabrication bioactive mesoporous calcium silicate/calcium phosphate cements (MCS/CPC) scaffolds with high mechanical strength by Freeform Fabrication System with Micro-Droplet Jetting. After preparation of ordered mesoporous calcium silicate (MCS) powder, ready-to-use MCS/CPC paste was formed by mixing calcium phosphate cement (CPC) powder and MCS powder with the binder polyvinyl alcohol (PVA) aqueous solution at a certain ratio of powder to liquid. MCS/CPC scaffolds with various architectures, pore sizes, and interconnectivity were then directly printed at room temperature using MCS/CPC paste. The mechanical strength, apatite formation, degradation rate, and cytocompatibility of the composite scaffolds were systematically investigated. The results showed that MCS/CPC paste exhibited outstanding printability to form MCS/CPC scaffolds. The hybrid MCS/CPC scaffolds with predefined pore size of 350 μm showed fast degradation rate, high mechanical strength, and good cytocompatibility. It was indicated that the hybrid MCS/CPC scaffolds might be a promising candidate for critical bone defect repair.

Similar content being viewed by others

References

Luo Y, Lode A, Sonntag F, Nies B, Gelinsky M (2013) Well-ordered biphasic calcium phosphate-alginate scaffolds fabricated by multi-channel 3D plotting under mild conditions. J Mater Chem B1(33):4088–4098

Lee G-S, Park J-H, Shin US, Kim H-W (2011) Direct deposited porous scaffolds of calcium phosphate cement with alginate for drug delivery and bone tissue engineering. Acta Biomater 7(8):3178–3186

Bohner M (2007) Reactivity of calcium phosphate cements. J Mater Chem 17(38):3980–3986

Liu C, Gai W, Pan S, Liu Z (2003) The exothermal behavior in the hydration process of calcium phosphate cement. Biomaterials 24(18):2995–3003

Liu C, Shen W, Gu Y (1997) Mechanism of hardening process for a hydroxyapatite cement. J Biomed Mater Res 35(1):75–80

Liu C, Huang Y, Zheng H (1999) Study on the hydration process of calcium phosphate cement by impedance spectroscopy. J Am Ceram Soc 82(4):1052–1057

Liu C, Shen W, Chen J (2009) Solution property of calcium phosphate cement hardening body. Mater Chem Phys 58(1):78–82

Takagi S, Chow LC (2001) Formation of macropores in calcium phosphate cement implants. J Mater Sci 12(2):135–139. doi:10.1023/A:1008917910468

Seol Y-J, Park DY, Park JY, Kim SW, Park SJ, Cho D-W (2013) A new method of fabricating robust freeform 3D ceramic scaffolds for bone tissue regeneration. Biotechnol Bioeng 110(5):1444–1455

Leong KF, Cheah CM, Chua CK (2003) Solid freeform fabrication of three-dimensional scaffolds for engineering replacement tissues and organs. Biomaterials 24(13):2363–2378

Barralet JE, Grover L, Gaunt T, Wright AJ, Gibson IR (2002) Preparation of macroporous calcium phosphate cement tissue engineering scaffold. Biomaterials 23(15):3063–3072

Deville S (2008) Freeze-casting of porous ceramics: a review of current achievements and issues. Adv Eng Mater 10(3):155–169

Si Hesarak, Zamanian A, Moztarzadeh F (2008) The influence of the acidic component of the gas-foaming porogen used in preparing an injectable porous calcium phosphate cement on its properties: acetic acid versus citric acid. J Biomed Mater Res B 86B(1):208–216

Miao X, Hu Y, Liu J, Wong AP (2004) Porous calcium phosphate ceramics prepared by coating polyurethane foams with calcium phosphate cements. Mater Lett 58(3–4):397–402

Yeong W-Y, Chua C-K, Leong K-F, Chandrasekaran M (2004) Rapid prototyping in tissue engineering: challenges and potential. Trends Biotechnol 22(12):643–652

Landers R, Mülhaupt R (2000) Desktop manufacturing of complex objects, prototypes and biomedical scaffolds by means of computer-assisted design combined with computer-guided 3D plotting of polymers and reactive oligomers. Macromol Mater Eng 282(1):17–21

Detsch R, Uhl F, Deisinger U, Ziegler G (2008) 3D-cultivation of bone marrow stromal cells on hydroxyapatite scaffolds fabricated by dispense-plotting and negative mould technique. J Mater Sci 19(4):1491–1496. doi:10.1007/s10856-007-3297-x

Miranda P, Pajares A, Saiz E, Tomsia AP, Guiberteau F (2008) Mechanical properties of calcium phosphate scaffolds fabricated by robocasting. J Biomed Mater Res Part A 85A(1):218–227

Wu C, Luo Y, Cuniberti G, Xiao Y, Gelinsky M (2011) Three-dimensional printing of hierarchical and tough mesoporous bioactive glass scaffolds with a controllable pore architecture, excellent mechanical strength and mineralization ability. Acta Biomater 7(6):2644–2650

Fu Q, Saiz E, Tomsia AP (2011) Bioinspired Strong and Highly Porous Glass Scaffolds. Adv Funct Mater 21(6):1058–1063

Seyednejad H, Gawlitta D, Dhert WJA, van Nostrum CF, Vermonden T, Hennink WE (2011) Preparation and characterization of a three-dimensional printed scaffold based on a functionalized polyester for bone tissue engineering applications. Acta Biomater 7(5):1999–2006

Park S, Kim G, Jeon Y, Koh Y, Kim W (2009) 3D polycaprolactone scaffolds with controlled pore structure using a rapid prototyping system. J Mater Sci 20(1):229–234. doi:10.1007/s10856-008-3573-4

Lode A, Meissner K, Luo Y, Sonntag F, Glorius S, Nies B, Vater C, Despang F, Hanke T, Gelinsky M (2014) Fabrication of porous scaffolds by three-dimensional plotting of a pasty calcium phosphate bone cement under mild conditions. J Tissue Eng Regen Med 8(9):682–693

Klammert U, Reuther T, Jahn C, Kraski B, Kubler AC, Gbureck U (2009) Cytocompatibility of brushite and monetite cell culture scaffolds made by three-dimensional powder printing. Acta Biomater 5(2):727–734

Gbureck U, Hözel T, Klammert U, Würzler K, Müller FA, Barralet JE (2007) Resorbable dicalcium phosphate bone substitutes prepared by 3D powder printing. Adv Funct Mater 17(3):3940–3945

Habibovic P, Gbureck U, Doillon CJ, Bassett DC, van Blitterswijk CA, Barralet JE (2008) Osteoconduction and osteoinduction of low-temperature 3D printed bioceramic implants. Biomaterials 29(7):944–953

Pati F, Jang J, Ha D-H, Kim SW, Rhie J-W, Shim J-H, Kim D-H, Cho D-W (2014) Printing three-dimensional tissue analogues with decellularized extracellular matrix bioink. Nat Commun 5:3935

Martínez-Vázquez FJ, Cabañas MV, Paris JL, Lozano D, Vallet-Regí M (2015) Fabrication of novel Si-doped hydroxyapatite/gelatine scaffolds by rapid prototyping for drug delivery and bone regeneration. Acta Biomater 15:200–209

Zhu M, Li K, Zhu Y, Zhang J, Ye X (2015) 3D-printed hierarchical scaffold for localized isoniazid/rifampin drug delivery and osteoarticular tuberculosis therapy. Acta Biomater 16:145–155

Zhao Q, Qian J, Zhou H, Yuan Y, Liu C (2010) In vitro osteoblast-like and endothelial cells’ response to calcium silicate/calcium phosphate cement. Biomed Mater 5(3):035004

Guo H, Wei J, Yuan Y, Liu C (2007) Development of calcium silicate/calcium phosphate cement for bone regeneration. Biomed Mater 2(3):153–159

Wu C, Fan W, Gelinsky M, Xiao Y, Simon P, Schulze R (2011) Bioactive SrO–SiO2 glass with well-ordered mesopores: characterization, physiochemistry and biological properties. Acta Biomater 7(4):1797–1806

Kokubo T, Takadama H (2006) How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27(15):2907–2915

Liu C, Shao H, Chen F, Zheng H (2003) Effects of the granularity of raw materials on the hydration and hardening process of calcium phosphate cement. Biomaterials 24(23):4103–4113

Yokoyama Y, Hattori S, Yoshikawa C, Yasuda Y, Koyama H, Takato T, Kobayashi H (2009) Novel wet electrospinning system for fabrication of spongiform nanofiber 3-dimensional fabric. Mater Lett 63(9–10):754–756

Li W-J, Laurencin CT, Caterson EJ, Tuan RS, Ko FK (2002) Electrospun nanofibrous structure: a novel scaffold for tissue engineering. J Biomed Mater Res 60(4):613–621

Dehghani F, Annabi N (2011) Engineering porous scaffolds using gas-based techniques. Curr Opin Biotechnol 22(5):661–666

del Real RP, Ooms E, Wolke JGC, Vallet-Regí M, Jansen JA (2003) In vivo bone response to porous calcium phosphate cement. J Biomed Mater Res Part A 65A(1):30–36

Xu HHK, Simon CG (2004) Self-hardening calcium phosphate cement–mesh composite: reinforcement, macropores, and cell response. J Biomed Mater Res Part A 69A(2):267–278

Wu C, Fan W, Zhou Y, Luo Y, Gelinsky M, Chang J, Xiao Y (2012) 3D-printing of highly uniform CaSiO3 ceramic scaffolds: preparation, characterization and in vivo osteogenesis. J Mater Chem 22(24):12288–12295

Guo H, Su J, Wei J, Kong H, Liu C (2009) Biocompatibility and osteogenicity of degradable Ca-deficient hydroxyapatite scaffolds from calcium phosphate cement for bone tissue engineering. Acta Biomater 5(1):268–278

Wu C, Ramaswamy Y, Boughton P, Zreiqat H (2008) Improvement of mechanical and biological properties of porous CaSiO3 scaffolds by poly(d, l-lactic acid) modification. Acta Biomater 4(2):343–353

Wu C, Chang J, Zhai W, Ni S (2007) A novel bioactive porous bredigite (Ca7MgSi4O16) scaffold with biomimetic apatite layer for bone tissue engineering. J Mater Sci 18(5):857–864. doi:10.1007/s10856-006-0083-0

Xu S, Lin K, Wang Z, Chang J, Wang L, Lu J, Ning C (2008) Reconstruction of calvarial defect of rabbits using porous calcium silicate bioactive ceramics. Biomaterials 29(17):2588–2596

Chou Y-F, Huang W, Dunn JCY, Miller TA, Wu BM (2005) The effect of biomimetic apatite structure on osteoblast viability, proliferation, and gene expression. Biomaterials 26(3):285–295

Luo Y, Wu C, Lode A, Gelinsky M (2013) Hierarchical mesoporous bioactive glass/alginate composite scaffolds fabricated by three-dimensional plotting for bone tissue engineering. Biofabrication 5(1):015005

Acknowledgements

This investigation was supported by the National Basic Research Program of China (973 Program: 2012CB933600), National Natural Science Foundation of China (No. 31370960, No. 31100678), National Science & Technology Pillar Program during the Twelfth Five-years Plan Period (No. 2012BAD32B01).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, C., Gao, L., Chen, F. et al. Fabrication of mesoporous calcium silicate/calcium phosphate cement scaffolds with high mechanical strength by freeform fabrication system with micro-droplet jetting. J Mater Sci 50, 7182–7191 (2015). https://doi.org/10.1007/s10853-015-9244-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9244-1