Abstract

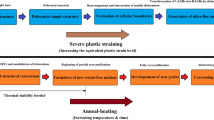

Ultrafine-grained (UFG) materials with grain sizes in the submicrometer or nanometer range may be prepared through the application of severe plastic deformation (SPD) to bulk coarse-grained solids. These materials generally exhibit high strength but only very limited ductility in low-temperature testing, thereby giving rise to the so-called paradox of strength and ductility. This paradox is examined and a new quantitative diagram is presented which permits the easy insertion of experimental data. It is shown that relatively simple procedures are available for achieving both high strength and high ductility in UFG materials including processing the material to a very high strain and/or applying a very short-term anneal immediately after the SPD processing. Significant evidence is now available demonstrating the occurrence of grain boundary sliding in these materials at low temperatures, where this is attributed to the presence of non-equilibrium grain boundaries and the occurrence of enhanced diffusion along these boundaries.

Similar content being viewed by others

References

Hall EO (1951) The deformation and ageing of mild steel: III discussion of results. Proc Phys Soc B 64:747–753

Petch NJ (1953) The cleavage strength of polycrystals. J Iron Steel Inst 173:25–28

Valiev RZ, Kaibyshev OA, Kuznetsov RI, Musalimov RSh, Tsenev NK (1988) Low-temperature superplasticity of metallic materials. Dokl Akad Nauk SSSR 301:864–866

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Bulk nanostructured materials from severe plastic deformation. Prog Mater Sci 45:103–189

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2006) Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 58(4):33–39

Alexander DJ (2007) New methods for severe plastic deformation processing. J Mater Eng Perform 16:360–374

Zhu Y, Valiev RZ, Langdon TG, Tsuji N, Lu K (2010) Processing of nanostructured metals and alloys via plastic deformation. MRS Bull 35:977–981

Estrin Y, Vinogradov A (2013) Extreme grain refinement by severe plastic deformation: a wealth of challenging science. Acta Mater 61:782–817

Langdon TG (2013) Twenty-five years of ultrafine-grained materials: achieving exceptional properties through grain refinement. Acta Mater 61:7035–7059

Huang Y, Langdon TG (2013) Advances in ultrafine-grained materials. Mater Today 16:85–93

Kawasaki M, Langdon TG (2014) Producing ultrafine-grained materials through severe plastic deformation. Emerging Mater Res 3:252–260

Zhilyaev AP, Kim BK, Nurislamova GV, Baró MD, Szpunar JA, Langdon TG (2002) Orientation imaging microscopy of ultrafine-grained nickel. Scripta Mater 46:575–580

Zhilyaev AP, Nurislamova GV, Kim BK, Baró MD, Szpunar JA, Langdon TG (2003) Experimental parameters influencing grain refinement and microstructural evolution during high-pressure torsion. Acta Mater 51:753–765

Wongsa-Ngam J, Kawasaki M, Langdon TG (2013) A comparison of microstructures and mechanical properties in a Cu–Zr alloy processed using different SPD techniques. J Mater Sci 48:4653–4660. doi:10.1007/s10853-012-7072-0

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 51:881–981

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53:893–979

Valiev RZ, Alexandrov IV, Zhu YT, Lowe TC (2002) Paradox of strength and ductility in metals processed by severe plastic deformation. J Mater Res 17:5–8

Valiev R (2002) Materials science - Nanomaterial advantage. Nature 419:887–889

Valiev R (2004) Nanostructuring of metals by severe plastic deformation for advanced properties. Nat Mater 3:511–516

Jia D, Wang YM, Ramesh KT, Ma E, Zhu YT, Valiev RZ (2001) Deformation behavior and plastic instabilities of ultrafine-grained titanium. Appl Phys Lett 79:611–613

Wang YM, Ma E (2004) Strain hardening, strain rate sensitivity, and ductility of nanostructured metals. Mater Sci Eng A 375–377:46–52

Zhu YT, Liao X (2004) Retaining ductility. Nat Mater 3:351–352

Wang Y, Chen M, Zhou F, Ma E (2002) High tensile ductility in a nanostructured metal. Nature 419:912–915

Wang YM, Ma E (2004) Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater 52:1699–1709

Horita Z, Ohashi K, Fujita T, Kaneko K, Langdon TG (2005) Achieving high strength and high ductility in precipitation-hardened alloys. Adv Mater 17:1599–1602

Zhao YH, Liao XZ, Cheng S, Ma E, Zhu YT (2006) Simultaneously increasing the ductility and strength of nanostructured alloys. Adv Mater 18:2280–2283

Zhao YH, Bingert JE, Liao XZ, Cui BZ, Han K, Sergueeva AV, Mukherjee AK, Valiev RZ, Langdon TG, Zhu YTT (2006) Simultaneously increasing the ductility and strength of ultra-fine-grained pure copper. Adv Mater 18:2949–2953

Ma E (2006) Eight routes to improve the tensile ductility of bulk nanostructured metals and alloys. JOM 58(4):49–53

Zhao YH, Bingert JF, Zhu YT, Liao XZ, Valiev RZ, Horita Z, Langdon TG, Zhou YZ, Lavernia EJ (2008) Tougher ultrafine grain Cu via high-angle grain boundaries and low dislocation density. Appl Phys Lett 92:081903

Zhao YH, Topping T, Bingert JF, Thornton JJ, Dangelewicz AM, Li Y, Liu W, Zhu YT, Zhou Y, Lavernia EJ (2008) High tensile ductility and strength in bulk nanostructured nickel. Adv Mater 20:3033

Zhao Y, Zhu Y, Lavernia EJ (2010) Strategies for improving tensile ductility of bulk nanostructured materials. Adv Eng Mater 12:769–778

Huang CX, Hu WP, Wang QY, Wang C, Yang G, Zhu YT (2015) An ideal ultrafine-grained structure for high strength and high ductility. Mater Res Lett 3:88–94

Zhao YH, Guo YZ, Wei A, Dangelewicz AM, Xu C, Zhu YT, Langdon TG, Zhou YZ, Lavernia EJ (2008) Influence of specimen dimensions on the tensile behavior of ultrafine-grained Cu. Scripta Mater 59:627–630

Zhao YH, Guo YZ, Wei Q, Topping TD, Dangelewicz AM, Zhu YT, Langdon TG, Lavernia EJ (2009) Influence of specimen dimensions and strain measurement methods on tensile stress-strain curves. Mater Sci Eng 525A:68–77

Mungole T, Kumar P, Kawasaki M, Langdon TG (2014) A critical examination of the paradox of strength and ductility in ultrafine-grained metals. J Mater Res 29:2534–2546

Valiev RZ, Sergueeva AV, Mukherjee AK (2003) The effect of annealing on tensile deformation behavior of nanostructured SPD titanium. Scripta Mater 49:669–674

Suo T, Li YI, Zhao F, Deng Q, Xie K (2011) Influence of short term annealing on strain hardening rate and flow stress of ultrafine grained material processed by severe plastic deformation. Mater Res Innov 15(s1):S69–S72

Semenova I, Salimgareeva G, Da Costa G, Lefebvre W, Valiev R (2010) Enhanced strength and ductility of ultrafine-grained Ti processed by severe plastic deformation. Adv Eng Mater 12:803–807

Polyakov AV, Semenova IP, Valiev RZ, Huang Y, Langdon TG (2013) Influencing of annealing on ductility of ultrafine-grained titanium processed by equal-channel angular pressing-Conform and drawing. MRS Commun 3:249–253

Maury N, Zhang NX, Huang Y, Zhilyaev AP, Langdon TG (2015) A critical examination of pure tantalum processed by high-pressure torsion. Mater Sci Eng A 638:174–182

Andreau O, Gubicza J, Zhang NX, Huang Y, Jenei P, Langdon TG (2014) Effect of short-term annealing on the microstructures and flow properties of an Al–1% Mg alloy processed by high-pressure torsion. Mater Sci Eng A 615:231–239

Kumar P, Xu C, Langdon TG (2009) Influence of strain rate on strength and ductility in an aluminum alloy processed by equal-channel angular pressing. J Mater Sci 44:3913–3916. doi:10.1007/s10853-009-3535-3

Gifkins RC, Langdon TG (1965) On the question of low-temperature sliding at grain boundaries. J Inst Metals 93:347–352

Ashby MF, Raj R (1970) Diffusion controlled sliding at serrated grain boundary. Scipta Metall 4:737–742

Langdon TG (2006) Grain boundary sliding revisited: developments in sliding over four decades. J Mater Sci 41:597–609. doi:10.1007/s10853-006-6476-0

Kawasaki M, Langdon TG (2007) Principles of superplasticity in ultrafine-grained materials. J Mater Sci 42:1782–1796. doi:10.1007/s10853-006-0954-2

Chinh NQ, Szommer P, Csanádi T, Langdon TG (2006) Flow processes at low temperatures in ultrafine-grained aluminum. Mater Sci Eng A434:326–344

Chinh NQ, Szommer P, Horita Z, Langdon TG (2006) Experimental evidence for grain-boundary sliding in ultrafine-grained aluminum processed by severe plastic deformation. Adv Mater 18:34–39

Ivanov KV, Naydenkin EV (2014) Tensile behavior and deformation mechanisms of ultrafine-grained aluminum processed using equal-channel angular pressing. Mater Sci Eng A606:313–321

Ivanov KV, Naydenkin EV (2014) The effect of strain rate on tensile behavior and deformation mechanisms of ultrafine-grained aluminum. IOP Conf Series. Mater Sci Eng 63:012123

Van Swygenhoven H, Caro A (1997) Plastic behavior of nanophase Ni: a molecular dynamics computer simulation. Appl Phys Lett 71:1652–1654

Schiøtz J, Di Tolla FD, Jacobsen KW (1998) Softening of nanocrystalline metals at very small grain sizes. Nature 391:561–563

Van Swygenhoven H, Derlet PM (2001) Grain-boundary sliding in nanocrystalline FCC metals. Phys Rev B 64:224105

Valiev RZ, Gertsman VYu, Kaibyshev OA, Khannanov ShKh (1983) Non-equilibrium state and recovery of grain-boundary structure. 1. General analysis, crystallogeometrical aspects. Phys Stat Solidi (a) 77:97–105

Valiev RZ, Korznikov AV, Mulyukov RR (1993) Structure and properties of ultrafine-grained materials produced by severe plastic deformation. Mater Sci Eng A168:141–148

Horita Z, Smith DJ, Furukawa M, Nemoto M, Valiev RZ, Langdon TG (1996) An investigation of grain boundaries in submicrometer-grained Al–Mg solid solution alloys using high-resolution electron microscopy. J Mater Res 11:1880–1890

Sauvage X, Wilde G, Divinski SV, Horita Z, Valiev RZ (2012) Grain boundaries in ultrafine grained materials processed by severe plastic deformation and related phenomenon. Mater Sci Eng A540:1–12

Wilde G, Ribbe J, Reglitz G, Wegner M, Rösner H, Estrin Y, Zehetbauer M, Setman D, Divinski S (2010) Plasticity and grain boundary diffusion at small grain sizes. Adv Eng Mater 12:758–764

Kolobov YR, Grabovetskaya GP, Ivanov MB, Zhilyaev AP, Valiev RZ (2001) Grain boundary diffusion characteristics of nanostructured nickel. Scipta Mater 44:873–878

Fujita T, Horita Z, Langdon TG (2002) Characteristics of diffusion in Al–Mg alloys with ultrafine grain sizes. Phil Mag A82:2249–2262

Wang ZB, Lu K, Wilde G, Divinski SV (2010) Interfacial diffusion in Cu with a gradient nanostructured surface layer. Acta Mater 58:2376–2386

Mungole T, Kumar P, Kawasaki M, Langdon TG (2015) The contribution of grain boundary sliding in tensile deformation of an ultrafine grained aluminum alloy having high strength and high ductility. J Mater Sci 50:3549–3561. doi:10.1007/s10853-015-8915-2

Bell RL, Graeme-Barber C, Langdon TG (1967) The contribution of grain boundary sliding to the overall strain of a polycrystal. Trans Met Soc AIME 239:1821–1824

Langdon TG (1972) The effect of surface configuration on grain boundary sliding. Metall Trans 3:797–801

Islamgaliev RK, Yunusova NF, Valiev RZ, Tsenev NK, Perevezentsev VN, Langdon TG (2003) Characteristics of superplasticity in an ultrafine-grained aluminum alloy processed by ECA pressing. Scipta Mater 49:467–472

Kumar P, Xu C, Langdon TG (2005) The significance of grain boundary sliding in the superplastic Zn–22% Al alloy after processing by ECAP. Mater Sci Eng A411–412:447–450

Huang Y, Langdon TG (2002) Characterization of deformation processes in a Zn-22% Al alloy using atomic force microscopy. J Mater Sci 37:4993–4998. doi:10.1023/A:1021071228521

Huang Y, Langdon TG (2003) Using atomic force microscopy to evaluate the development of mesoscopic shear planes in materials processed by severe plastic deformation. Mater Sci Eng A358:114–121

Han JH, Mohamed FA (2011) Quantitative measurements of grain boundary sliding in an ultrafine-grained Al alloy by atomic force microscopy. Metall Mater Trans A42:3969–3978

Langdon TG (1994) An evaluation of the strain contributed by grain boundary sliding in superplasticity. Mater Sci Eng A174:225–230

Clarisse L, Bataille A, Pennec Y, Crampon J, Duclos R (1999) Investigation of grain boundary sliding during superplastic deformation of a fine-grained alumina by atomic force microscopy. Ceram Int 25:389–394

Kini M, Chokshi AH (2010) The influence of titania on creep in superplastic zirconia. J Am Ceram Soc 93:1725–1731

Ghosh S, Chokshi AH (2014) Creep in nanocrystalline zirconia. Scripta Mater 86:13–16

Eaton P, West P (2010) Atomic Force Microscopy. Oxford University Press, Oxford

Yang K, Fecht HJ, Ivanisenko Y (2014) First direct in situ observation of grain boundary sliding in ultrafine grained noble metal. Adv Eng Mater 16:517–521

Roy S, Suwas S (2013) Deformation mechanism during superplastic testing of Ti–6Al–4 V–0.1B alloy. Mater Sci Eng A574:205–217

Chinh NQ, Győri T, Valiev RZ, Szommer P, Varga G, Havancsák K, Langdon TG (2012) Observations of unique plastic behavior in micro-pillars of an ultrafine-grained alloy. MRS Commun 2:75–78

Chinh NQ, Valiev RZ, Sauvage X, Varga G, Havancsák K, Kawasaki M, Straumal BB, Langdon TG (2014) Grain boundary phenomena in an ultrafine-grained Al–Zn alloy with improved mechanical behavior for micro-devices. Adv Eng Mater 16:1000–1009

Greer JR, Oliver WC, Nix WD (2005) Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater 53:1821–1830

Greer JR, Nix WD (2006) Nanoscale gold pillars strengthened through dislocation starvation. Phy Rev B 73:245410

Ng KS, Ngan AHW (2008) Stochastic nature of plasticity of aluminum micro-pillars. Acta Mater 56:1712–1720

Shao S, Abdolrahim N, Bahr DF, Lin G, Zbib HM (2014) Stochastic effects in plasticity in small volumes. Int J Plast 52:117–132

Crosby T, Po G, Erel C, Ghoniem N (2015) The origin of strain avalanches in sub-micron plasticity of fcc metals. Acta Mater 89:123–132

Acknowledgements

This work was supported in part by IISc-STC grant # ISTC0305 and a Seed Grant (Indian Institute of Science, Bangalore) to PK, in part by the NRF Korea funded by MoE under Grant No. NRF-2014R1A1A2057697 to MK and in part by the National Science Foundation of the United States under Grant No. DMR-1160966 and the European Research Council under ERC Grant Agreement No. 267464-SPDMETALS to TGL.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, P., Kawasaki, M. & Langdon, T.G. Review: Overcoming the paradox of strength and ductility in ultrafine-grained materials at low temperatures. J Mater Sci 51, 7–18 (2016). https://doi.org/10.1007/s10853-015-9143-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9143-5