Abstract

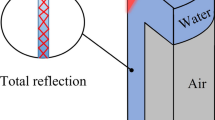

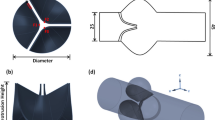

The electric field distribution, the jet motion, and the resultant fiber morphology are systematically studied for a single needle and a “hole” electrospinning system. The 3D electric fields and the jet bending processes of the two configurations are simulated. High-speed photography is adopted to capture the jet motion during electrospinning. Four parameters including the straight jet length, the amplitude and frequency of the whipping process, and the velocity of the bending jet are measured to characterize the development of the jet motion. The results show that the hole electrospinning setup produces shorter straight jet length, smaller envelope cone, but higher whipping frequency, and lower jet dropping velocity. These factors result in fine and uniform fibers produced from the “hole” electrospinning system.

Similar content being viewed by others

References

Zhang Y, Chwee TL, Ramakrishna S, Huang ZM (2005) J Mater Sci Mater Med 16:933

Burger C, Hsiao BS, Chu B (2006) Annu Rev Mater Res 36:333

Rebouillat S, Lyons M (2011) Int J Electrochem Sci 6:5731

Varabhas JS, Chase GG, Reneker DH (2008) Polymer 49:4226

Dosunmu OO, Chase GG, Kataphinan W, Reneker DH (2006) Nanotechnology 17:1123

Zhou FL, Gong RH, Isaac P (2009) J Mater Sci 44:5501. doi:10.1007/s10853-009-3768-1

Thoppey NM, Bochinski JR, Clarke LI, Gorga RE (2010) Polymer 51:4928

Theron S, Yarin AL, Zussman E, Kroll E (2005) Polymer 46:2889

Alessio V, Fabio R, Giorgio M, Claudio T, Renato C (2010) Polym Int 59:1606

Srivastava Y, Loscertales I, Marquez M, Thorsen T (2008) Microfluid Nanofluid 4:245

Niu HT, Lin T, Wang XG (2009) J Appl Polym Sci 114:3524

He JH, Liu Y (2008) Chaos Soliton Fract 37:643

Yarin AL, Zussman E (2004) Polymer 45:2977

Wang X, Niu HT, Lin T (2009) Polym Eng Sci 49:1582

Thoppey NM, Bochinski JR, Clarke LI, Gorga RE (2011) Nanotechnology 22:345301

Forward KM, Rutledge GC (2012) Chem Eng J 183:492

Xie S, Zeng YC (2012) Ind Eng Chem Res 51:5336

Sun YF, Zeng YC, Wang XH (2011) Ind Eng Chem Res 50:1099

Reneker DH, Yarin AL, Fong H, Koombhongse S (2000) J Appl Phys 87:4531

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (11272088), Shanghai Dawning Program (10SG33), the Fundamental Research Funds for the Central Universities, and the Chinese Universities Scientific Fund (NCET-DH-D-2013035).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zheng, Y., Xie, S. & Zeng, Y. Electric field distribution and jet motion in electrospinning process: from needle to hole. J Mater Sci 48, 6647–6655 (2013). https://doi.org/10.1007/s10853-013-7465-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7465-8