Abstract

Carbon fibers are widely used as a reinforcement in composite materials because of their high-specific strength and modulus. Current trends toward the development of carbon fibers have been driven in two directions; ultrahigh tensile strength fiber with a fairly high strain to failure (~2 %), and ultrahigh modulus fiber with high-thermal conductivity. Today, a number of ultrahigh strength polyacrylonitrile (PAN)-based (more than 6 GPa), and ultrahigh modulus pitch-based (more than 900 GPa) carbon fibers have been commercially available. In the present work, the tensile properties of polyimide-coated PAN-based (T1000GB, T300, and M60JB) and pitch-based (K13D and XN-05) carbon fibers have been investigated using a single-filament tensile test. The pyromellitic dianhydride/4-4′-oxydianiline polyimide coating was deposited on the carbon fiber surface using high-temperature vapor deposition polymerization (VDPH). The Weibull statistical distributions of the tensile strength were characterized. The results clearly show that the VDPH polyimide coating improves the tensile strength and the Weibull modulus of PAN- and pitch-based carbon fibers.

Similar content being viewed by others

Notes

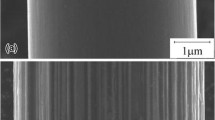

The polyimides were non-conducting materials and might be coated with a conducting layer to prevent specimen charging effects. However, the carbon fibers were conducting materials (the one end of carbon fiber was fixed with a conducting tape) and the thickness of polyimide coating was quite thin in this study. The specimen charging effects were as small as they could ignore. Therefore, the polyimide-coated carbon fiber surfaces were not coated with a conductive (gold, platinum, graphite, or osmium etc.) layer.

The sizing materials and polyimides were non-conducting materials and might be coated with a conducting layer to prevent specimen charging effects. However, the carbon fibers were conducting materials (the one end of carbon fiber was fixed with a conducting tape) and the thickness of polyimide coating (or sizing) was quite thin in this study. The specimen charging effects were as small as they could ignore. Therefore, the as-received (with sizing) and polyimide-coated carbon fiber surfaces were not coated with a conductive (gold, platinum, graphite or osmium etc.) layer.

References

Fitzer E (1989) Carbon 27(5):621. doi:10.1016/0008-6223(89)90197-8

Chand S (2000) J Mater Sci 35(6):1303. doi:10.1023/A:1004780301489

Rosa LG, Colella A, Anjinho CA (2006) Mater Sci Forum 514–516:672. doi:10.4028/www.scientific.net/MSF.514-516.672

Kumar S, Wang Y (1997) In: Mallick PK (ed) Composites engineering handbook. Dekker, New York, p 51

Naito K, Tanaka Y, Yang JM, Kagawa Y (2008) Carbon 46(2):189. doi:10.1016/j.carbon.2007.11.001

Naito K, Tanaka Y, Yang JM, Kagawa Y (2009) J Am Ceram Soc 92(1):186. doi:10.1111/j.1551-2916.2008.02868.x

Juska TD, Puckett PM (1997) In: Mallick PK (ed) Composites engineering handbook. Dekker, New York, p 101

Aggour L, Fitzer E, Ignotowitz E, Sahebkar M (1974) Carbon 12(3):358. doi:10.1016/0008-6223(74)90079-7

Vincent H, Vincent C, Scharef JP, Mourichoux H, Bouix J (1992) Carbon 30(3):495. doi:10.1016/0008-6223(92)90049-3

Piquero T, Vincent H, Vincent C, Bouix J (1995) Carbon 33(4):455. doi:10.1016/0008-6223(94)00170-5

Wang YQ, Zhou BL, Wang ZM (1995) Carbon 33(4):427. doi:10.1016/0008-6223(94)00167-X

Emig G, Popovska N, Schoch G, Stumm T (1998) Carbon 36(4):407. doi:10.1016/S0008-6223(97)00213-3

R’Mili’ M, Massardier V, Merle P, Vincent H, Vincent C (1999) Carbon 37(1):129. doi:10.1016/S0008-6223(98)00197-3

Labruquere S, Blanchard H, Pailler R, Naslain R (2002) J Eur Ceram Soc 22(7):1001. doi:10.1016/S0955-2219(01)00410-1

Gawad OA, Abou Tabl MH, Hamid ZA, Mostafa SF (2006) Surf Coat Technol 201(3–4):1357. doi:10.1016/j.surfcoat.2006.02.001

Baklanova NI, Zima TM, Boronin AI, Kosheev SV, Titov AT, Isaeva NV, Graschenkov DV, Solntsev SS (2006) Surf Coat Technol 201(6):2313. doi:10.1016/j.surfcoat.2006.03.046

Subramanian RV, Nyberg EA (1992) J Mater Res 7(3):677. doi:10.1557/JMR.1992.0677

Matsumoto A, Tsutsumi K, Kaneko K (1992) Langmuir 8(10):2515. doi:10.1021/la00046a027

Landry CC, Barron AR (1995) Carbon 33(4):381. doi:10.1016/0008-6223(94)00162-S

Zeng QB (1998) J Appl Polym Sci 70(1):177. doi:10.1002/(SICI)1097-4628(19981003)70:1<177:AID-APP17>3.0.CO;2-4

Peng P, Li XD, Yuan GF, She WQ, Cao F, Yang DM, Zhou Y, Liao J, Yang SL, Yue MJ (2001) Mater Lett 47(3):171. doi:10.1016/S0167-577X(00)00231-7

Richards VN, Vohs JK, Fahlman BD, Williams GL (2005) J Am Ceram Soc 88(7):1973. doi:10.1111/j.1551-2916.2005.00248.x

Downs WB, Baker RTK (1991) Carbon 29(8):1173. doi:10.1016/0008-6223(91)90035-H

Zhu S, Su CH, Lehoczky SL, Muntele I, Ila D (2003) Diam Relat Mater 12(10–11):1825. doi:10.1016/S0925-9635(03)00205-X

Tzeng SS, Hung KH, Ko TH (2006) Carbon 44(5):859. doi:10.1016/j.carbon.2005.10.033

Zhao JO, Liu L, Guo QG, Shi JL, Zhai GT, Song JR, Liu ZJ (2008) Carbon 46(2):380. doi:10.1016/j.carbon.2007.11.021

Bekyarova E, Thostenson ET, Yu A, Kim H, Gao J, Tang J, Hahn HT, Chou TW, Itkis ME, Haddon RC (2007) Langmuir 23(7):3970. doi:10.1021/la062743p

Thostenson ET, Li WZ, Wang DZ, Ren ZF, Chou TW (2002) J Appl Phys 91(9):6034. doi:10.1063/1.1466880

Qian H, Bismarrck A, Greenhalgh ES, Kalinka G, Shaffer MSP (2008) Chem Mater 20(5):1862. doi:10.1021/cm702782j

Naito K, Yang JM, Tanaka Y, Kagawa Y (2008) Appl Phys Lett 92(23):231912. doi:10.1063/1.2944258

Gao SL, Mader E, Plonka R (2008) Compos Sci Technol 68(14):2892. doi:10.1016/j.compscitech.2007.10.009

Gao SL, Mader E, Plonka R (2007) Acta Mater 55(3):1043. doi:10.1016/j.actamat.2006.09.020

Kim JK, Mai YW (1991) J Mater Sci 26(17):4702. doi:10.1007/BF00612409

Skourlis T, Duvis T, Papaspyrides CD (1993) Compos Sci Technol 48(1–4):119. doi:10.1016/0266-3538(93)90127-3

Varelidis PC, McCullough RL, Papaspyrides CD (1999) Compos Sci Technol 59(12):1813. doi:10.1016/S0266-3538(99)00039-1

Subramanian RV, Jakubowski JJ, Williams FD (1978) J Adhesion 9(3):185. doi:10.1080/00218467808075113

Dujardin S, Lazzaroni R, Rigo L, Riga J, Verbist JJ (1986) J Mater Sci 21(12):4342. doi:10.1007/BF01106553

Zinger B, Shkolnik S, Höcke H (1989) Polymer 30(4):628. doi:10.1016/0032-3861(89)90146-8

Drzal LT (1983) J Adhesion 16(2):133. doi:10.1080/00218468308074911

Dauksys RJ (1973) J Adhesion 5(3):211. doi:10.1080/00218467308075021

Naganuma T, Naito K, Yang JM, Kyono J, Sasakura D, Kagawa Y (2009) Compos Sci Technol 69(7–8):1319. doi:10.1016/j.compscitech.2009.03.002

Naganuma T, Naito K, Yang JM, Kyono J, Sasakura D, Kagawa Y (2009) In: Fielding J, Tate L, Prybla S, Beckwith SW (eds) SAMPE 09 (Changing times-New opportunities-Are you prepared? 54th International SAMPE Symposium, May 19-21, 2009). DEStech Publications, Lancaster

Naganuma T, Naito K, Yang JM (2011) Carbon 49(12):3881. doi:10.1016/j.carbon.2011.05.026

Kubono A, Higuchi H, Umemoto S, Okui N (1993) Thin Solid Films 232(2):256. doi:10.1016/0040-6090(93)90018-K

Hatori H, Yamada Y, Shiraishi M, Takahashi Y (1991) Carbon 29(4–5):679. doi:10.1016/0008-6223(91)90138-9

ASTM C1557–03 (2008) ASTM annual book of standards, vol 15.01. American Society for Testing and Materials, West Conshohocken. doi:10.1520/C1557-03R08

Sung MG, Sassa K, Tagawa T, Miyata T, Ogawa H, Doyama M, Yamada S, Asai S (2002) Carbon 40(11):2013. doi:10.1016/S0008-6223(02)00059-3

Weibull W (1951) J Appl Mech 18:293

Johnson W (1985) In: Watt W, Perov BV (eds) Strong fibers, vol 1. Elsevier, Amsterdam, p 389

Naito K, Yang JM, Tanaka Y, Kagawa Y (2012) J Mater Sci 47(2):632. doi:10.1007/s10853-011-5832-x

Naito K, Yang JM, Inoue Y, Fukuda H (2012) J Mater Sci 47(23):8044. doi:10.1007/s10853-012-6694-6

Acknowledgements

This work was supported by JSPS (Japan Society for the Promotion of Science) KAKENHI 22360282 and JST (Japan Science and Technology Agency) through Advanced Low Carbon Technology Research and Development Program (ALCA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naito, K. The effect of high-temperature vapor deposition polymerization of polyimide coating on tensile properties of polyacrylonitrile- and pitch-based carbon fibers. J Mater Sci 48, 6056–6064 (2013). https://doi.org/10.1007/s10853-013-7402-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7402-x