Abstract

Carbon fibers are widely used as reinforcements in composite materials because of their high specific strength and modulus. Today, a number of ultrahigh strength polyacrylonitrile (PAN)-based (more than 6 GPa), and ultrahigh modulus pitch-based (more than 900 GPa) carbon fibers have been commercially available. In contrast, carbon nanotube (CNT) with the extremely high tensile strength have attracted attention as reinforcements. An interesting technique to modify the carbon fiber is CNT grafting on the carbon fiber surface. CNT-grafted carbon fibers offer the opportunity to add the potential benefits of nanoscale reinforcement to well-established fibrous composites to create micro-nano multiscale hybrid composites. In the present study, the tensile properties of CNT grown on T1000GB PAN- and K13D pitch-based carbon fibers have been investigated. Single filament tensile test at gauge lengths of 1, 5, and 25 mm were conducted. The effect of gauge length on tensile strength and Weibull modulus of CNT-grafted PAN- and pitch-based carbon fibers were evaluated. It was found that grafting of CNT improves the tensile strength and Weibull modulus of PAN- and pitch-based carbon fibers with longer gauge length (≥5 mm). The results also clearly show that for CNT-grafted and as-received PAN- and pitch-based carbon fibers, there is a linear relation between the Weibull modulus and the average tensile strength on log–log scale.

Similar content being viewed by others

Notes

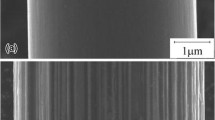

The cross-sections of the T1000GB PAN-based and the K13D pitch-based carbon fibers are almost circular. The T1000GB fiber has a particulate or granular microstructure. The K13D fiber has a sheet-like microstructure. The fractured surfaces of the T1000GB PAN-based carbon fiber show the initiation of failure from surface defects and a rough, rather poorly defined granular texture. However, the K13D pitch-based fiber obscures the initiation of failure and observes the crystallite sheets are a result of pull out at failure [2, 3, 12].

References

Chand S (2000) J Mater Sci 35(6):1303. doi:10.1023/A:1004780301489

Naito K, Tanaka Y, Yang JM, Kagawa Y (2008) Carbon 46(2):189. doi:10.1016/j.carbon.2007.11.001

Naito K, Tanaka Y, Yang JM, Kagawa Y (2009) J Am Ceram Soc 92(1):186. doi:10.1111/j.1551-2916.2008.02868.x

Demczyk BG, Wang YM, Cunnings J, Hetman M, Han W, Zettl A, Ritchie RO (2002) Mat Sci Eng A Struct 334(1–2):173. doi:10.1016/S0921-5093(01)01807-X

Tran CD, Humphries W, Smith SM, Huynh C, Lucas S (2009) Carbon 47(11):2662. doi:10.1016/j.carbon.2009.05.020

Zhang X, Li Q, Tu Y, Li Y, Coulter JY, Zheng LX, Zhao YH, Jia QX, Peterson DE, Zhu YT (2007) Small 3(2):244. doi:10.1002/smll.200600368

Tzeng SS, Hung KH, Ko TH (2006) Carbon 44(5):859. doi:10.1016/j.carbon.2005.10.033

Zhao JO, Liu L, Guo QG, Shi JL, Zhai GT, Song JR, Liu ZJ (2008) Carbon 46(2):380. doi:10.1016/j.carbon.2007.11.021

Bekyarova E, Thostenson ET, Yu A, Kim H, Gao J, Tang J, Hahn HT, Chou TW, Itkis ME, Haddon RC (2007) Langmuir 23(7):3970. doi:10.1021/la062743p

Thostenson ET, Li WZ, Wang DZ, Ren ZF, Chou TW (2002) J Appl Phys 91(9):6034. doi:10.1063/1.1466880

Qian H, Bismarck A, Greenhalgh ES, Kalinka, Shaffer MSP (2008) Chem Mater 20(5):1862. doi:10.1021/cm702782j

Naito K, Yang JM, Tanaka Y, Kagawa Y (2008) Appl Phys Lett 92(23):231912-1. doi:10.1063/1.2944258

Padgett WJ, Durham SD, Mason AM (1995) J Compos Mater 29(14):1873. doi:10.1177/002199839502901405

Pickering KL, Murray TL (1999) Compos Part A 30(8):1017. doi:10.1016/S1359-835X(99)00003-2

Paiva MC, Bernardo CA, Nardin M (2000) Carbon 38(9):1323. doi:10.1016/S0008-6223(99)00266-3

Naito K, Yang JM, Tanaka Y, Kagawa Y (2012) J Mater Sci 47(2):632. doi:10.1007/s10853-011-5832-x

ASTM C1557-03 (2008) Standard test method for tensile strength and young’s modulus of fibers. ASTM annual book of standards, vol 15.01. American Society for Testing and Materials, West Conshohocken. doi:10.1520/C1557-03R08

Sung MG, Sassa K, Tagawa T, Miyata T, Ogawa H, Doyama M, Yamada S, Asai S (2002) Carbon 40(11):2013. doi:10.1016/S0008-6223(02)00059-3

Morimoto T, Nakagawa S, Ogihara S (2005) JSME Int J Series A 48(4):194. doi:10.1299/jsmea.48.194

Weibull W (1951) J Appl Mech 18:293

Lu CS, Danzer R, Fischer FD (2002) J Am Ceram Soc 85(6):1640. doi:10.1111/j.1151-2916.2002.tb00330.x

Danzer R (2006) J Eur Ceram Soc 26(15):3043. doi:10.1016/j.jeurceramsoc.2005.08.021

Acknowledgements

This study was supported by JSPS (Japan Society for the Promotion of Science) KAKENHI 22360282 and JST (Japan Science and Technology Agency) through Advanced Low Carbon Technology Research and Development Program (ALCA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naito, K., Yang, JM., Inoue, Y. et al. The effect of surface modification with carbon nanotubes upon the tensile strength and Weibull modulus of carbon fibers. J Mater Sci 47, 8044–8051 (2012). https://doi.org/10.1007/s10853-012-6694-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6694-6