Abstract

The tensile properties and fracture behavior of polyacrylonitrile (PAN)- and pitch-based hybrid carbon fiber/polyimide composites with several types of nanoparticles (25 nm C, 20–30 nm β-SiC, 130 nm β-SiC, 80 nm SiO2, and 300 nm SiO2) added to the matrix were investigated. The tensile stress–strain curves of PAN- and pitch-based hybrid carbon fiber/polyimide composites with 25 nm C, 20–30 nm β-SiC, and 80 nm SiO2 nanoparticles have complex shapes (jagged trace), whereas the tensile response of hybrid carbon fiber/polyimide composites with 130 nm β-SiC and 300 nm SiO2 nanoparticles indicates an instantaneous failure. The stress after the initial failure in hybrid carbon fiber/polyimide composites improves by adding 25 nm C, 20–30 nm β-SiC, and 80 nm SiO2 nanoparticles to the matrix and correlates with the fracture toughness of the polyimide matrix.

Similar content being viewed by others

Notes

These values were obtained from the producer’s data sheet. The tensile modulus of the T1000GB PAN-based and K13D pitch-based carbon fibers were measured using a single filament tensile test at a gauge length of 25 mm, and they were 291 ± 11 and 940 ± 48 GPa, respectively [14].

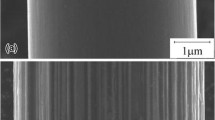

Producer’s data sheet. The diameters of all nanoparticles were also measured using a high-magnification transmission electron microscope (TEM) (JEM 2000, JEOL) at an operating voltage of 200 kV.

The thickness of individual (T1000GB and K13D) and hybrid carbon fiber/polyimide composites was similar at approximately1.5 mm.

This size is relatively smaller than the distance between each fibers related to the V f = 50 % (the distance between each fibers at V f = 50 % are similar to the diameters of each fiber).

In our previous investigation [34], the natural crack at the tip of a notch was introduced by tapping the fresh blades. The natural cracks at the tip of a notch for a few bulk polyimides with nanoparticles were also produced using fatigue loading to check the procedure (tapping procedure), and G IC of these bulk polyimides was similar to that obtained by tapping cracked bulk polyimides.

References

Fitzer E (1989) Carbon 27(5):621. doi:10.1016/0008-6223(89)90197-8

Chand S (2000) J Mater Sci 35(6):1303. doi:10.1023/A:1004780301489

Bunsell AR, Harris B (1974) Composites 5(4):157. doi:10.1016/0010-4361(74)90107-4

Summerscales J, Short D (1978) Composites 9(3):157. doi:10.1016/0010-4361(78)90341-5

Aveston J, Kelly A (1980) Philos T R Soc A 294(1411):519. doi:10.1098/rsta.1980.0061

Hayashi T, Koyama K, Yamazaki A, Kihira M (1972) Fukugo Zairyo (composite materials) 1:21

Short D, Summerscales J (1979) Composites 10(4):215. doi:10.1016/0010-4361(79)90022-3

Short D, Summerscales J (1980) Composites 11(1):33. doi:10.1016/0010-4361(80)90019-1

Hardaker KM, Richardson MOW (1980) Polym-Plast Technol 15(2):169. doi:10.1080/03602558008070011

Chow TW, Kelly A (1980) Ann Rev Mater Sci 10:229. doi:10.1146/annurev.ms.10.080180.001305

Morgan P (2005) Properties of carbon fibers. In: Morgan P (ed) Carbon fibers and their composites. Taylor, New York, p 791

Huang Y, Young RJ (1995) Carbon 33(2):97. doi:10.1016/0008-6223(94)00109-D

Paris O, Loidl D, Peterlik H (2002) Carbon 40(4):551. doi:10.1016/S0008-6223(01)00139-7

Naito K, Tanaka Y, Yang JM, Kagawa Y (2008) Carbon 46(2):189. doi:10.1016/j.carbon.2007.11.001

Naito K, Tanaka Y, Yang JM, Kagawa Y (2009) J Am Ceram Soc 92(1):186. doi:10.1111/j.1551-2916.2008.02868.x

Naito K, Yang JM, Tanaka Y, Kagawa Y (2012) J Mater Sci 47(2):632. doi:10.1007/s10853-011-5832-x

Landis AL, Lau KSY (1998) In: Goodman SH (ed) Handbook of thermoset plastics, 2nd edn. Noyes, New Jersey, p 302

Sroog CE (1996) In: Ghosh MK, Mittal KL (eds) Polyimides: fundamentals and applications. Dekker, New York, p 1

Bekyarova E, Thostenson ET, Yu A, Kim H, Gao J, Tang J, Hahn HT, Chou TW, Itkis ME, Haddon RC (2007) Langmuir 23(7):3970. doi:10.1021/la062743p

Hussain M, Nakahira A, Niihara K (1996) Mater Lett 26(3):185. doi:10.1016/0167-577X(95)00224-3

Timmerman JF, Hayes BS, Seferis JC (2002) Compos Sci Technol 62(9):1249. doi:10.1016/S0266-3538(02)00063-5

Siddiqui NA, Woo RSC, Kim JK, Leung CCK, Munir A (2007) Compos Part A-Appl S 38(2):449. doi:10.1016/j.compositesa.2006.03.001

Xu Y, Van Hoa S (2008) Compos Sci Technol 68(3–4):854. doi:10.1016/j.compscitech.2007.08.013

Thostenson ET, Li WZ, Wang DZ, Ren ZF, Chou TW (2002) J Appl Phys 91(9):6034. doi:10.1063/1.1466880

Yokozeki T, Iwahori Y, Ishiwata S (2007) Compos Part A-Appl S 38(3):917. doi:10.1016/j.compositesa.2006.07.005

Iwahori Y, Ishiwata S, Sumizawa T, Ishikawa T (2005) Compos Part A-Appl S 36(10):1430. doi:10.1016/j.compositesa.2004.11.017

Arai M, Noro Y, Sugimoto K, Endo M (2008) Compos Sci Technol 68(2):516. doi:10.1016/j.compscitech.2007.06.007

Yang Y, Lu CX, Su XL, Wang XK (2007) J Mater Sci 42(15):6347. doi:10.1007/s10853-006-1198-x

Cho J, Chen JY, Daniel IM (2007) Scr Mater 56(8):685. doi:10.1016/j.scriptamat.2006.12.038

Jiang ZY, Zhang H, Zhang Z, Murayama H, Okamoto K (2008) Compos Part A-Appl S 39(11):1762. doi:10.1016/j.compositesa.2008.08.005

Ogasawara T, Ishida Y, Kasai T (2009) Compos Sci Technol 69(11–12):2002. doi:10.1016/j.compscitech.2009.05.003

MSDS of skybond 703 polyimide resin (1996) Industrial Summit Technology Co., Shenzhen

ASTM D792-08 (2009) In: ASTM annual book of standards, vol 08.01. American Society for Testing and Materials, West Conshohocken. doi:10.1520/D0792-08

Naito K, Yang JM, Kagawa Y (2011) Mat Sci Eng A-Struct 530:357. doi:10.1016/j.msea.2011.09.096

Zhou YX, Pervin F, Rangari VK, Jeelani S (2006) Mat Sci Eng A-Struct 426(1–2):221. doi:10.1016/j.msea.2006.04.031

ASTM D3171-11 (2011) In: ASTM annual book of standards, vol 15.03. American Society for Testing and Materials, West Conshohocken. doi:10.1520/D3171-11

Saunders RA, Lekakou C, Bader MG (1999) Compos Sci Technol 59(7):933. doi:10.1016/S0266-3538(98)00137-7

Thomason JL (1995) Composites 26(7):467. doi:10.1016/0010-4361(95)96804-F

Marom G, Fischer S, Tuler FR, Wagner HD (1978) J Mater Sci 13(7):1419. doi:10.1007/BF00553194

Stevanovic MM, Stecenko TB (1992) J Mater Sci 27(4):941. doi:10.1007/BF01197646

Yao L, Li WB, Wang N, Li W, Guo X, Qiu YP (2007) J Mater Sci 42(16):6494. doi:10.1007/s10853-007-1534-9

Kretsis G (1987) Composites 18(1):13. doi:10.1016/0010-4361(87)90003-6

You YJ, Park YH, Kim HY, Park JS (2007) Comps Struct 80(1):117. doi:10.1016/j.compstruct.2006.04.065

Tada H, Paris PC, Irwin GR (2000) In: Tada H, Paris PC, Irwin GR (eds) The stress analysis of cracks handbook, 3rd edn. The American Society of Mechanical Engineers (ASME), New York, p 487. doi:10.1115/1.801535.fm

Hwang SF, Shen BC (1999) Compos Sci Technol 59(12):1861. doi:10.1016/S0266-3538(99)00047-0

Naito K, Yang JM, Kagawa Y (2012) J Mater Sci 47(6):2743. doi:10.1007/s10853-011-6101-8

Acknowledgments

This study was supported by JSPS (Japan Society for the Promotion of Science) KAKENHI 22360282 and JST (Japan Science and Technology Agency) through Advanced Low Carbon Technology Research and Development Program (ALCA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naito, K. Tensile properties of polyacrylonitrile- and pitch-based hybrid carbon fiber/polyimide composites with some nanoparticles in the matrix. J Mater Sci 48, 4163–4176 (2013). https://doi.org/10.1007/s10853-013-7229-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7229-5