Abstract

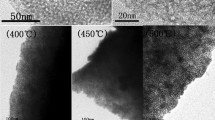

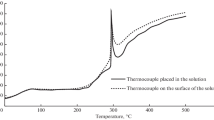

Zirconia was synthesized by sol–gel and post-hydrothermal treatment under autogenous pressure in order to study the effect of synthesis methods on its structural and textural properties. On the basis of thermal analysis, in situ X-ray diffraction and Raman spectroscopy techniques, the synthesis processes exhibit similar thermal behavior and zirconia phase transformation. The effect of in situ calcination temperature on the crystallization behavior, crystal phase transition, and crystallite size analysis was studied. The results obtained revealed that amorphous zirconia transformed into tetragonal phase above 400 °C and thermally stabilized up to 700 °C. A biphasic mixture of tetragonal and monoclinic zirconia was formed at 750 °C. Activation energy of sintering due to grain growth mechanism predicted that the zirconia phase transformation is due to the increase in the crystallite size of tetragonal phase above its critical size. The post-hydrothermal treatment resulted in the formation of high surface area mesoporous zirconia (213 m2 g−1). Upon increasing the calcination temperature, a pronounced decrease in the specific surface area of zirconia samples due to sintering process and phase transformation.

Similar content being viewed by others

References

Hoek A, Minderhout JK, Post MFM, Lednor PW (1984) Process for the preparation of a Fischer–Tropsch catalyst, a catalyst so prepared and use of this catalyst in the preparation of hydrocarbons. EP 0110449, 13 June

Chigapov AN, Graham GW, Gandhi HS, Jen HW (2007) US Patent 7,229,948, 12 June 2007

Matsuzawa K (2001) US Patent 6,326,328, 4 Dec 2001

Skovgaard M, Almdal K, van Lelieveld A (2011) J Mater Sci 46:1824. doi:10.1007/s10853-010-5007-1

Cimino S, Pirone R, Lisi L (2002) Appl Catal B 35:243. doi:10.1016/S0926-3373(01)00262-4

Yamaguchi T (1994) Catal Today 20:199. doi:10.1016/0920-5861(94)80003-0

Gandhi HS (1998) US Patent 4-806-519, 21 Feb

Duchet JC, Tilliete MJ, Cornet D (1991) Catal Today 10:507. doi:10.1016/0920-5861(91)80036-9

Gopalan R, Chang CH, Lin YS (1995) J Mater Sci 30:3075. doi:10.1007/BF01209219

Mercera PDL, Van Ommen JG, Doesburg EBM, Burggraaf AJ, Ross JRH (1991) Appl Catal A 71:363. doi:10.1016/0166-9834(91)85092-A

Yan QZ, Su XT, Huang ZY, Ge CC (2006) J Eur Ceram Soc 26:915. doi:10.1016/j.jeurceramsoc.2004.11.017

Hwang SM, Park GC, Lim JH, Joo J (2012) J Mater Sci 47:5216. doi:10.1007/s10853-012-6405-3

Torres-Huerta AM, Dominguez-Crespo MA, Onofre-Bustamante E, Flores-Vela A (2012) J Mater Sci 47:2300. doi:10.1007/s10853-011-6044-0

Gao P, Meng LJ, Dos Santos MP, Teixeira V, Andritschky M (2000) Thin Solid Films 377:32. doi:10.1016/S0040-6090(00)01395-X

Garvie RC (1965) J Phys Chem 69:1238. doi:10.1021/j100888a024

Garvie RC (1978) J Phys Chem 82:218. doi:10.1021/j100491a016

Murase Y, Kato E (1979) J Am Ceram Soc 62:527. doi:10.1111/j.1151-2916.1979.tb19121.x

Murase Y, Kato E (1983) J Am Ceram Soc 66(3):196. doi:10.1111/j.1151-2916.1983.tb10016.x

Livage J, Doi K, Mazieres C (1968) J Am Ceram Soc 51:349. doi:10.1111/j.1151-2916.1968.tb15952.x

Mitsuhashi T, Ichihara M, Tatsukc U (1974) J Am Ceram Soc 57:97. doi:10.1111/j.1151-2916.1974.tb10823.x

Osendi MI, Moya JS, Serna CJ, Soria J (1985) J Am Ceram Soc 68:135. doi:10.1111/j.1151-2916.1985.tb09651.x

Tani E, Yoshimura M, Somiya S (1983) J Am Ceram Soc 66(l):11. doi:10.1111/j.1151-2916.1983.tb09958.x

Feng RM, Yang XJ, Ji WJ, Au CT (2008) Mater Chem Phys 107(1):132. doi:10.1016/j.matchemphys.2007.06.055

Kaya C, He JY, Gu X, Butler EG (2002) Microporous Mesoporous Mater 54:37. doi:10.1016/S1387-1811(02)00334-7

Wan Y, Ma JX, Zhou W, Zhu YJ, Song XY, Li HX (2004) Appl Catal A 277:55. doi:10.1016/j.apcata.2004.08.022

Hung IM, Hung DT, Fung KZ, Hon MH (2006) J Eur Ceram Soc 26:2627. doi:10.1016/j.jeurceramsoc.2005.07.069

Chang Q, Zhou J, Wang Y, Meng G (2009) Adv Powder Technol 20:371. doi:10.1016/j.apt.2009.06.001

Chen H, Wang Y (2002) Ceram Int 28:541. doi:10.1016/S0272-8842(02)00007-X

Yu J, Shi JL, Wang LZ, Ruan ML, Yan DS (2001) Mater Lett 48:112. doi:10.1016/S0167-577X(00)00289-5

Ye F, Dong Z, Zhang H (2010) Mater Lett 64:1441. doi:10.1016/j.matlet.2010.03.049

Deshmane VG, Adewuyi YG (2012) Microporous Mesoporous Mater 148:88. doi:10.1016/j.micromeso.2011.07.012

Hudson MJ, Knowles JA (1996) J Mater Chem 6:89. doi:10.1039/jm9960600089

Ciesla U, Fröba M, Stucky G, Schüth F (1999) Chem Mater 11:227. doi:10.1021/cm980205v

Chen SL, Jang LY, Cheng S (2006) J Phys Chem B 110:11761. doi:10.1021/jp060564a

Toraya H, Yoshimura M, Somiya S (1984) J Am Ceram Soc 67:C119. doi:10.1111/j.1151-2916.1984.tb19715.x

Jaenicke S, Ghuah GK, Raju V, Nie YT (2008) Catal Surv Asia 12:153. doi:10.1007/s10563-008-9048-2

Srinivasan R, De Angelis R, Davis BH (1986) J Mater Res 1:583. doi:10.1557/JMR.1986.0583

Srinivasan R, Rice L, Davis BH (1990) J Am Ceram Soc 73:3528. doi:10.1111/j.1151-2916.1990.tb06492.x

Garvie RC, Goss MF (1986) J Mater Sci 21:1253. doi:10.1007/BF00553259

Basahel SN, Abd El-Maksod IH, Abu-Zied BM, Mokhtar M (2010) J Alloys Compd 493:630. doi:10.1016/j.jallcom.2009.12.169

Yamamoto T, Tanaka T, Takenaka S, Yoshida S, Onari T, Takahashi Y, Kosaka T, Hasegawa S, Kudo M (1999) J Phys Chem B 103:2385. doi:10.1021/jp984378j

Mercera PDL, Van Ommen JG, Doesburg EBM, Burggraaf AJ, Ross JRH (1990) Appl Catal 57:127. doi:10.1016/S0166-9834(00)80728-9

Gregg SJ, Sing KSW (1982) Adsorption, surface area and porosity, 2nd edn. Academic Press, London

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) Pure Appl Chem 57:603. doi:10.1351/pac198557040603

Basahel SN, Tarek TA, Narasimharao K, Bagabas AA, Mokhtar M (2012) Mater Res Bull 47:3463. doi:10.1016/j.materresbull.2012.07.003

Landau MV, Titelman L, Shapira-Tchelet AM, Wilson P, Tavor D, Vradman L, Wolfson A (2005) Stud Surf Sci Catal 156:385. doi:10.1016/S0167-2991(05)80233-2

Blin JL, Gigot L, Léonard A, Su BL (2002) Stud Surf Sci Catal 141:257. doi:10.1016/S0167-2991(02)80550-X

Rana S, Mallick S, Parida KM (2011) Ind Eng Chem Res 50:2055. doi:10.1021/ie101777a

Huang YY, McCarthy TJ, Sachtler WMH (1996) Appl Catal A 148:135. doi:10.1016/S0926-860X(96)00223-2

Acknowledgements

This project was funded by the Deanship of Scientific Research (DSR), King Abdulaziz University, Jeddah, under Grant No. MS/12/474. The authors, therefore, acknowledge with thanks DSR technical and financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mokhtar, M., Basahel, S.N. & Ali, T.T. Effect of synthesis methods for mesoporous zirconia on its structural and textural properties. J Mater Sci 48, 2705–2713 (2013). https://doi.org/10.1007/s10853-012-7068-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7068-9