Abstract

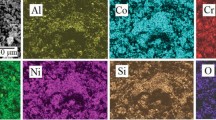

Cr3C2 ceramic powder is added in varying amounts to AISI 410 stainless steel powder to develop AISI 400 based alloys with varying chromium and carbon content using the coaxial laser deposition technique operating at parameter sets which guarantee full melting of the constituent powder particles. Theoretical isothermal curves for the in situ generated alloys are correlated with the as-deposited and heat-treated microstructures using electron microscopy, X-ray and electron backscatter diffraction techniques. It is concluded that with an increased carbon loading in the mixture, post-deposition heat treatment involving full re-austenitising and tempering is necessary in order to reduce the effect of solute trapping which negatively affects the material mechanical properties.

Similar content being viewed by others

References

Abboud JH, Rawlings RD, West DRF (1995) J Mater Sci 30:5931

Wang F, Mei J, Wu X (2007) Mater Des 28:2040

Lin X, Yue TM, Yang HO et al (2005) Mater Sci Eng A 391:325

Ensz MT, Griffith ML, Rechaway DE (2002) In: Proceedings of the 2002 international conference on metal powder deposition for rapid manufacturing, vol 1, p 195

Pei X, Wang J, Wan Q et al (2011) Surf Coat Technol 205:4380

Yue TM, Li T (2008) Surf Coat Technol 202:3043

Atwood C, Griffith M, Harwell L et al (1998) ICALEO 11:16

Lim JS, Ng KL, Teh KM (2008) SIMtech 9:142–147

Pinkerton AJ, Li L (2004) J Manuf Sci Eng 126:33

Richter KH, Orban S, Nowotny S (2004) In: ICALEO 23

Jouvard JM, Grevey D, Lemoine F et al (1997) J Phys III 7:2265–2274

de Oliveira U, Ocelik V, De Hosson JTM (2005) Surf Coat Technol 197:127

Anandkumar R, Almeida A, Vilar R et al (2009) Surf Coat Technol 204:285

Fenech M, Grech M, Betts JC (2012) Surf Coat Technol 207:211

ASM International (1993) ASM handbook, 10th edn, vol 1. ASM International, Materials Park, OH, pp 2011

Chen J, Wang S, Xue L (2012) J Mater Sci 47:779

Chen J, Conlon K, Xue L et al (2010) Mater Sci Eng A 527:7265

Mahmoudi B, Torkamany MJ, Aghdam ARSR et al (2010) Mater Des 31:2553

Wang L, Felicelli SD, Pratt P (2008) Mater Sci Eng A 496:234

Lin YC, Chen SC (2003) J Mater Process Technol 138:22

Sourmail T, Garcia-Mateo C (2005) Comput Mater Sci 34:323

Yang H, Bhadeshia HKDH (2009) Scr Mater 60:493

Guimarães J, Rios P (2010) J Mater Sci 45:1074

Yang H-, Jang JH, Bhadeshia HKDH et al (2012) Calphad 36:16

Hemmati I, Ocelík V, De Hosson J (2011) J Mater Sci 46:3405

Chen J, Xue L, Wang S (2011) J Mater Sci 46:5859

Colaco R, Vilar R (2004) Mater Sci Eng A 385:123

Vamsi Krishna B, Bandyopadhyay A (2009) Mater Des 30:1490

Tsai MC, Chiou CS, Du JS et al (2002) Mater Sci Eng A 332:1

Costa L, Deus AM, Reti T et al (2002) In: Proceedings of the 2002 international conference on metal powder deposition for rapid manufacturing, pp 172–176

Costa L, Vilar R, Reti T et al (2005) Mater Sci Forum 473:315–320

Andrews KW (1965) J Iron Steel Int 203:721–727

Tsymbalist MM, Rudenskaya NA, Kuz’min BP et al (2003) Prot Met 39:338

Lin C, Lai H, Kuo J et al (2011) Mater Charact 62:1124

Kurz W, Fisher DJ (1984) Fundamentals of solidification, 1st edn. Trans. Tech. Publications, Switzerland

Acknowledgements

The authors would like to thank ERDF (Malta) for the financing of the testing equipment through the project: “Developing an Interdisciplinary Material Testing and Rapid Prototyping R&D Facility (Ref. no. 012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fenech, M., Mallia, B., Grech, M. et al. Post-deposition heat treatment of co-deposited Cr3C2 and AISI 410 stainless steel using the coaxial laser deposition technique. J Mater Sci 48, 2224–2235 (2013). https://doi.org/10.1007/s10853-012-6998-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6998-6