Abstract

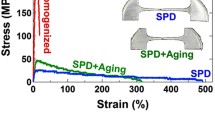

Processing by severe plastic deformation (SPD) typically increases the strength of metals and alloys drastically by decreasing their grain size into the submicrometer or nanometer range but the ductility of such materials remains typically low. This report describes the first demonstration that it is possible to increase the room temperature ductility of aluminum-based alloys processed by SPD and to attain elongations to failure of >150% while retaining the enhanced strength. This unique combination of properties is due to the occurrence of grain boundary sliding at room temperature. The sliding was obviously achieved by introducing a grain boundary wetting of the aluminum/aluminum grain boundaries.

Similar content being viewed by others

References

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2006) JOM 58(4):33

Zhu YT, Liao X (2004) Nat Mater 3:351

Koch CC, Morris DG, Lu K, Inoue A (1999) MRS Bull 24:54

Wang Y, Chen M, Zhou F, Ma E (2002) Nature 419:912

Zhao YH, Bingert JF, Liao XZ, Cui BZ, Han K, Sergueeva A, Mukherjee AK, Valiev RZ, Langdon TG, Zhu YT (2006) Adv Mater 18:2949

Zhao YH, Zhu YT, Liao XZ, Horita Z, Langdon TG (2006) Appl Phys Lett 89:121906

Zhao YH, Liao XZ, Cheng S, Ma E, Zhu YT (2006) Adv Mater 18:2280

Horita Z, Ohashi K, Fujita T, Kaneko K, Langdon TG (2005) Adv Mater 17:1599

Tao KX, Choo H, Li HQ, Clausen B, Jin JE, Lee YK (2007) Appl Phys Lett 90:101911

Valiev R, Gunderov D, Prokofiev E, Pushin V, Zhu Y (2008) Mater Trans 49(1):97

Valiev R (2004) Nat Mater 3:511

Valiev RZ, Salimonenko DA, Tsenev NK, Berbon PB, Langdon TG (1997) Scripta Mater 37:1945

Langdon TG (2009) J Mater Sci 44:5998. doi:10.1007/s10853-009-3780-5

Murashkin MYu, Kilmametov AR, Valiev RZ (2008) Phys Met Metallogr 106(1):90

Zhilyaev AP, Langdon TG (2008) Prog Mater Sci 53:893

Klug HP, Alexander LE (1974) X-ray diffraction procedures for polycrystalline and amorphous materials. Wiley, New York

Chinh NQ, Gubicza J, Kovács Zs, Lendvai J (2004) J Mater Res 19:31

Straumal BB, Baretzky B, Mazilkin AA, Phillipp F, Kogtenkova OA, Volkov MN, Valiev RZ (2004) Acta Mater 52:4469

Mazilkin AA, Straumal BB, Rabkin E, Baretzky B, Enders S, Protasova SG, Kogtenkova OA, Valiev RZ (2006) Acta Mater 54:3933

Chinh NQ, Vörös Gy, Szommer P, Horita Z, Langdon TG (2006) Mater Sci Forum 503–504:1001

Meyer MA, Mishra A, Benson DJ (2006) JOM 58(4):41

Zhang K, Weertman JR, Eastman JA (2005) Appl Phys Lett 87:061921

Zhang K, Weertman JR, Eastman JA (2004) Appl Phys Lett 85:5197

Man J, Obrtlík K, Polák J (2003) Mater Sci Eng A 351:123

Man J, Petrenec M, Obrtlík K, Polák J (2004) Acta Mater 52:5551

Choi Y, Lee HS, Kwon D (2004) J Mater Res 19:3307

Langdon TG (1994) Mater Sci Eng A174:225

Straumal BB, Kogtenkova O, Zięba P (2008) Acta Mater 56:925

Straumal BB (2003) Grain boundary phase transitions. Nauka publishers, Moscow

Straumal BB, Mazilkin AA, Kogtenkova OA, Protasova SG, Baretzky B (2007) Philos Mag Lett 87:423

Straumal BB, Gornakova AS, Kogtenkova OA, Protasova SG, Sursaeva VG, Baretzky B (2008) Phys Rev B 78:054202

Massalski TB (ed) (1990) Binary alloy phase diagrams, 2nd edn. ASM International, Materials Park, OH, p 238

Straumal B, Valiev R, Kogtenkova O, Zieba P, Czeppe T, Bielanska E, Faryna M (2008) Acta Mater 56:6123

Gao YJ, Han YJ (2003) Mater Sci Forum 475–479:3131

Straumal BB, Kogtenkova OA, Protasova SG, Nekrasov AN, Baretzky B (2010) JETP Lett 92, in press

Kilmametov AR, Vaughan G, Yavari AR, LeMoulec A, Botta WJ, Valiev RZ (2009) Mater Sci Eng A 503:10

Valiev RZ, Kozlov EV, Ivanov YuF, Lian J, Nazarov AA, Baudelet B (1994) Acta Metall Mater 42:2467

Acknowledgements

We thank Mr. Peter Szommer for assistance with the AFM measurements. This work was supported by the Russian Foundation for Basic Research under Grants No. 08-08-97044 and 09-08-92656 and Federal Agency for Science and Innovations (RZV, MYuM, ARK), the Russian Foundation for Basic Research under Grants No. 09-03-92481, 09-03-00784 and 08-08-91302) (BBS), the Hungarian Scientific Research Fund, OTKA, under Grant No. K67692 and K81360 (NQC) and the National Science Foundation of the United States under Grant No. DMR-0855009 (TGL).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Valiev, R.Z., Murashkin, M.Y., Kilmametov, A. et al. Unusual super-ductility at room temperature in an ultrafine-grained aluminum alloy. J Mater Sci 45, 4718–4724 (2010). https://doi.org/10.1007/s10853-010-4588-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4588-z