Abstract

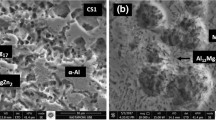

In this paper, rapid solidified Mg95Zn4.3Y0.7 (at.%) alloy powders produced by an inert gas atomizer were consolidated using a severe plastic deformation technique of high pressure torsion (HPT) at room temperature and 373 K. The behavior of powder consolidation, matrix microstructural evolution, and mechanical properties of the powders and compacts were investigated using X-ray diffraction, scanning electron microscopy, transmission electron microscopy, microhardness, and tensile testing. As the HPT processing temperature increases, the powders are more plastically deformed due to decreased deformation resistance, grain boundaries are more in equilibrium, powder bonding is enhanced due to increased interparticle diffusion, hence, tensile ductility and strength increases. On the other hand, hardness decreases with the increased processing temperature, due to less dislocation density.

Similar content being viewed by others

References

http://en.wikipedia.org/wiki/Magnesium. Accessed 17 March 2012

Estrin Y, Yi SB, Brokmeier HG, Zuberova Z, Yoon SC, Kim HS, Hellmig RJ (2008) Int J Mater Res 99:50

Kim WJ, Hong SI, Lee KH (2010) Metal Mater Inter 16:171

Kim DH, Lim HK, Kim YK, Kyeong JS, Kim WT, Kim DH (2011) Metal Mater Inter 17:383

Suzuki M, Kimura T, Koike J, Maruyama K (2003) Scripta Mater 48:997

Kim SH, Kim DH, Kim NJ (1997) Mater Sci Eng A 226–228:1030

Shin B, Kim Y, Bae D (2008) J Korean Inst Met Mater 46:1

Shin B, Yoon S, Ha C, Yun S, Bae D (2010) Korean J Met Mater 48:116

Kang MG, So TI, Jung HC, Shin KS (2011) Korean J Met Mater 49:686

Lee BD, Baek UH, Jang KS, Han JW, Son HT (2011) Korean J Met Mater 49:440

Bae DH, Kim SH, Kim DH, Kim WT (2002) Acta Mater 50:2343

Kim DH, Kim YK, Kim WT, Kim DH (2011) Korean J Met Mater 49:145

Cai J, Ma GC, Liu Z, Zhang HF, Hu ZQ (2006) J Alloy Compd 422:92

Nishida M, Kawamura Y, Yamamoto T (2004) Mater Sci Eng A 375–377:1217

Crivello J-C, Nobuki T, Kuji T (2007) Intermetallics 15:1432

Kawamura Y, Hayashi K, Inoue A, Masumoto T (2001) Mater Trans 42:1172

Inoue A, Kawamura Y, Matsushita M, Hayashi K, Koike J (2001) J Mater Res 16:1894

Yoon SC, Bok CH, Seo MH, Hong SJ, Kim HS (2008) J Korean Powder Metal Inst 15:31

Kim HS (2002) Mater Sci Eng A 328:317

Kim TS, Chae HJ, Lee JK, Jung HG, Bae JC (2007) Mater Sci Forum 534:793

Kim HS, Estrin Y, Bush MB (2000) Acta Mater 48:493

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2006) JOM 58:33

Kim HS, Seo MH, Hong SI (2000) Mater Sci Eng A 291:86

Zhilyaev AP, Langdon TG (2008) Prog Mater Sci 53:893

Song YP, Yoon EY, Lee DJ, Lee JW, Kim HS (2011) Mater Sci Eng A 528:4840

Stolyarov VV, Zhu YT, Lowe TC, Islamgaliev RK, Valiev RZ (2000) Mater Sci Eng A 282:78

Alexandrov IV, Zhang K, Kilmametov AR, Lu K, Valiev RZ (1997) Mater Sci Eng A 234–236:331

Hong SJ, Kim T-S, Kim HS, Kim WT, Chun BS (1999) Mater Sci Eng A 271:469

Kim T-S, Chae HJ (2008) Rev Adv Mater Sci 18:769

Kim T-S (2010) J Alloys Compd 504S:S496

Amaral LF, Oliveira IR, Salomao R, Frollini E, Pandolfelli VC (2010) Ceram Int 36:1047

Chae HJ, Kim YD, Kim T-S (2011) J Alloys Compd 509S:S250

Acknowledgements

This study was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MEST) (No. 2010-0026981).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoon, E.Y., Lee, D.J., Kim, TS. et al. Microstructures and mechanical properties of Mg–Zn–Y alloy consolidated from gas-atomized powders using high-pressure torsion. J Mater Sci 47, 7117–7123 (2012). https://doi.org/10.1007/s10853-012-6408-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6408-0