Abstract

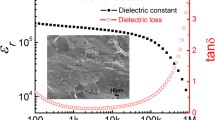

In this study (0–3) P(VDF-TrFE)/BaTiO3 composites containing up to 60 vol% of ceramic phase were prepared by solvent casting or compression molding. Their thermomechanical, dielectric, and piezoelectric properties were investigated, and discussed in the light of the properties of the basic components, the processing route and the resulting morphology. The crystalline structure of the P(VDF-TrFE) matrix was found to be highly dependent on the processing route, while the structure of BaTiO3 was not affected by any of the processing steps. The mechanical properties of the solvent cast materials showed a maximum at 30 vol% BaTiO3, while they increased monotonically with BaTiO3 content for compression molded materials. This difference was attributed to a higher amount of porosity and inhomogeneities in the solvent cast composites. Permittivity as high as 120 and piezoelectric coefficient d 33 up to 32 pC/N were obtained for compression molded composites, and the observed decrease in d 33 with aging time was attributed to the effect of mechanical stress release in the polymer matrix.

Similar content being viewed by others

References

Dias CJ, Dasgupta DK (1994) In: Ferroelectric polymers and ceramic-polymer composites. Key engineering materials, vol 92–9. Trans Tech Publications, Clausthal Zellerfe, p 217

Akdogan EK, Allahverdi M, Safari A (2005) IEEE Trans Ultrason Ferroelectr Freq Control 52(5):746

Newnham RE, Skinner DP, Cross LE (1978) Mater Res Bull 13(5):525

Han KH, Safari A, Riman RE (1991) J Am Ceram Soc 74(7):1699

Sa-Gong C, Safari A, Newnham RE (1986) In: IEEE proceedings of the 6th international symposium on applications of ferroelectrics, Bethlehem, p 281. doi:10.1109/ISAF.1986.201142

Yamamoto T, Urabe K, Banno H (1993) Jpn J Appl Phys 32:4272

Chau KH, Wong YW, Shin FG (2007) Appl Phys Lett 91(25):3. doi:10.1063/1.2827571

Capsal JF, Dantras E, Dandurand J, Lacabanne C (2006) J Non-Cryst Solids 353:4437. doi:10.1016/j.jnoncrysol.2007.01.097

Petchsuk A, Supmak W, Thanaboonsombut A (2009) J Appl Polym Sci 114(2):1048. doi:10.1002/app.30636

Ploss B, Ng W-Y, Chan HL-W, Ploss B, Choy C-L (2001) Compos Sci Technol 61(7):957

Ploss B, Shin FG, Chan HLW, Choy CL (2000) IEEE Trans Dielectr Electr Insul 7(4):517

Chan HLW, Ng PKL, Choy CL (1999) Appl Phys Lett 74(20):3029

Zeng R, Kwok KW, Chan HLW, Choy CL (2002) J Appl Phys 92(5):2674. doi:10.1063/1.1497699

Helke G, Lubitz K (2008) In: Heywang W, Lubitz K, Wersing W (eds) Piezoelectricity. Evolution and future of a technology. Springer series in materials science, vol 114. Springer, Berlin, p 89

Chen XD, Yang DB, Jiang YD, Wu ZM, Li D, Gou FJ, Yang JD (1998) Sens Actuators, A 65(2–3):194

Yao JL, Xiong CX, Dong LJ, Chen C, Lei YA, Chen L, Li R, Zhu QM, Liu XF (2009) J Mater Chem 19(18):2817. doi:10.1039/b819910h

Kerimov MK, Kurbanov MA, Musaeva SN, Geidarov GM, Aliev GG (2009) Tech Phys Lett 35(2):166. doi:10.1134/s1063785009020205

Panda PK (2009) J Mater Sci 44(19):5049. doi:10.1007/s10853-009-3643-0

Karaki T, Yan K, Miyamoto T, Adachi M (2007) Jpn J Appl Phys 46(4):L97. doi:10.1143/jjap.46.l97

Xu JW, Moon KS, Pramanik P, Bhattacharya S, Wong CP (2007) IEEE Trans Compon Packag Technol 30(2):248. doi:10.1109/tcapt.2007.898352

Dang ZM, Wang HY, Xu HP (2006) Appl Phys Lett 89(11):3. doi:10.1063/1.2338529

Dang ZM, Xu HP, Wang HY (2007) Appl Phys Lett 90(1):3. doi:10.1063/1.2393150

Dang Z-M, Yu Y-F, Xu H-P, Bai J (2008) Compos Sci Technol 68(1):171

Kim P, Doss NM, Tillotson JP, Hotchkiss PJ, Pan MJ, Marder SR, Li JY, Calame JP, Perry JW (2009) ACS Nano 3(9):2581. doi:10.1021/nn9006412

Luo XT, Chen LF, Chen XJ, Huang QJ (2004) J Mater Sci Technol 20(4):441

Chan HLW, Cheung MC, Choy CL (1999) Ferroelectrics 224(1–4):541

Patil R, Ashwin A, Radhakrishnan S (2007) Sens Actuators, A 138(2):361. doi:10.1016/j.sna.2007.05.025

Muralidhar C, Pillai PKC (1986) IEEE Trans Electr Insul 21(3):501

Venkatragavaraj E, Satish B, Vinod PR, Vijaya MS (2001) J Phys D-Appl Phys 34(4):487

Dietze M, Krause J, Solterbeck CH, Es-Souni M (2007) J Appl Phys 101: 054113. doi:10.1063/1.2653978

Mao YP, Mao SY, Ye ZG, Xie ZX, Zheng LS (2010) J Appl Phys 108: 014102. doi:10.1063/1.3443582

Lam KH, Wang XX, Chan HLW (2005) Compos A Appl Sci Manuf 36(11):1595. doi:10.1016/j.compositesa.2005.03.007

Dang ZM, Yuan JK, Zha JW, Zhou T, Li ST, Hu GH (2012) Prog Mater Sci 57(4):660

Chanmal CV, Jog JP (2008) Express Polym Lett 2(4):294. doi:10.3144/expresspolymlett.2008.35

Cheung MC, Chan HLW, Choy CL (2001) Ferroelectrics 264(1–4):1721

Dang ZM, Zheng Y, Xu HP (2008) J Appl Polym Sci 110(6):3473. doi:10.1002/app.28856

Gregorio R, Cestari M, Bernardino FE (1996) J Mater Sci 31(11):2925. doi:10.1007/bf00356003

Iijima M, Sato N, Wuled Lenggoro I, Kamiya H (2009) Colloids Surf A 352(1–3):88

Muralidhar C, Pillai PKC (1989) Ferroelectrics 89:17

Muralidhar C, Pillai PKC (1987) J Mater Sci Lett 6(3):346

Patsidis A, Psarras GC (2008) Express Polym Lett 2(10):718. doi:10.3144/expresspolymlett.2008.85

Ramajo L, Castro MS, Reboredo MM (2007) Compos A Appl Sci Manuf 38(8):1852

Ramajo L, Reboredo M, Castro M (2005) Compos A Appl Sci Manuf 36(9):1267. doi:10.1016/j.compositesa.2005.01.026

Kar-Gupta R, Venkatesh TA (2008) Acta Mater 56(15):3810

Chandradass J, Bae DS (2008) Mater Manuf Processes 23(2):117. doi:10.1080/10426910701774320

Marra SP, Ramesh KT, Douglas AS (1999) The mechanical properties of lead-titanate/polymer 0–3 composites. Compos Sci Technol 59(14):2163

Marra SP, Ramesh KT, Douglas AS (1999) Smart Mater Struct 8(1):57

Dutta PK, Asiaie R, Akbar SA, Zhu W (1994) Chem Mater 6(9):1542. doi:10.1021/cm00045a011

Baeten F, Derks B, Coppens W, van Kleef E (2006) J Eur Ceram Soc 26(4–5):589

Lovinger AJ, Furukawa T, Davis GT, Broadhurst MG (1983) Polymer 24(10):1225

Kodama H, Takahashi Y, Furukawa T (1997) Ferroelectrics 203(1):433

Gregorio RJ, Botta MM (1998) J Polym Sci Part B 36(3):403

Simoes R, Rodriguez-Perez M, De Saja J, Constantino C (2009) Polym Eng Sci 49(11):2150. doi:10.1002/pen.21455

Yagi T, Tatemoto M, Sako J (1980) Polym J 12(4):209

Sencadas V, Lanceros-Méndez S, Mano JF (2006) J Non-Cryst Solids 352(50–51):5376

Zhang SH, Klein RJ, Ren KL, Chu BJ, Zhang X, Runt J, Zhang QM (2006) J Mater Sci 41(1):271. doi:10.1007/s10853-006-6081-2

Hashin Z, Shtrikman S (1963) J Mech Phys Solids 11(2):127

Dent AC, Bowen CR, Stevens R, Cain MG, Stewart M (2007) J Eur Ceram Soc 27(13–15):3739. doi:10.1016/j.jeurceramsoc.2007.02.031

Tessier-Doyen N, Glandus JC, Huger M (2007) J Mater Sci 42(14):5826. doi:10.1007/s10853-006-1386-8

Jayasundere N, Smith BV (1993) J Appl Phys 73(5):2462

Kerner EH (1956) Proc Phys Soc B 69(8):802

Acknowledgements

The authors would like to thank the Swiss Federal Office of Energy (OFEN) and Swiss National Science Foundation (SNF) for funding, Solvay Solexis SpA for kindly providing P(VDF-TrFE) and for fruitful discussion, Li Jin for preparing the in house made BaTiO3 powder and Arthur Aebersold for technical support. The Laboratory of Powder Technology (LTP) and the Interdisciplinary Centre for Electron Microscopy (CIME) at EPFL are also acknowledged for support and access to their equipment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vacche, S.D., Oliveira, F., Leterrier, Y. et al. The effect of processing conditions on the morphology, thermomechanical, dielectric, and piezoelectric properties of P(VDF-TrFE)/BaTiO3 composites. J Mater Sci 47, 4763–4774 (2012). https://doi.org/10.1007/s10853-012-6362-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6362-x