Abstract

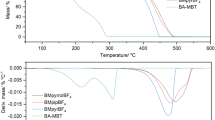

The effect of conductive carbon black (CCB) on the physico-mechanical, thermal, and electrical properties have been investigated by various characterization techniques. Physico-mechanical properties of the vulcanizates were studied with variation of filler loading, which revealed that the tensile strength increased up to 20 phr (parts per hundred rubber) CCB loading, whereas at higher filler loading it decreased marginally. Furthermore, tensile modulus, tear strength, and hardness gradually increased with increase in filler loading. The compression set and abrasion loss decreased with increasing CCB loading. The bound rubber content (Bdr) of unvulcanized rubber was found to increase significantly with increasing CCB content. The crosslink density increased, whereas the swelling decreased with CCB loading. The thermal stability of the vulcanizates evaluated by thermogravimetric analysis (TGA) showed a minor increment with increase in CCB content. It is observed from the dynamic mechanical thermal analysis (DMTA) that the storage modulus (E′), loss modulus (E″), and glass transition temperature (T g) of ethylene acrylic elastomer (AEM) matrix increased by incorporation of CCB. The dielectric relaxation characteristics of AEM vulcanizates such as dielectric permittivity (ε′), electrical conductivity (σ ac), and electric moduli (M′ and M″) have been studied as a function of frequency (101 to 106 Hz) at different filler loading. The variation of ε′ with frequency and filler loading was explained based on the interfacial polarization of the fillers within a heterogeneous system. The ε′ increased with increasing the CCB loading and it decreased with applied frequency. The frequency dependency of σ ac was investigated using conduction path theory and percolation threshold limit. The σ ac increased with increase in both CCB concentration and applied frequency. The M′ increased with applied frequency, however, it decreased above 30 phr filler. The M″ peak shifted towards higher frequency region and above 20 phr filler loading the peaks were not observed within the tested frequency region. The electromagnetic interference shielding effectiveness (EMISE) was studied in the X-band frequency region (8–12 GHz), which significantly improved with increase in CCB loading.

Similar content being viewed by others

References

Bokobza L (2007) Polymer 48:4907

Sau KP, Chaki TK, Khastgir D (1999) J Appl Polym Sci 71:887

Sridhar V, Choudhary RNP, Tripathy DK (2006) J Appl Polym Sci 102:1809

Mahapatra SP, Sridhar V, Chaudhary RNP, Tripathy DK (2007) Polym Eng Sci 47:984

Nanda M, Tripathy DK (2008) Express Polym Lett 2:855

Rahaman M, Chaki TK, Khastgir D (2011) J Mater Sci 46:3989. doi:10.1007/s10853-011-5326-x

Das NC, Chaki TK, Khastgir D (2002) Carbon 40:807

Mahapatra SP, Sridhar V, Chaudhary RNP, Tripathy DK (2007) Polym Compos 28:657

Tanrattanakul V, Bunchuay A (2007) J Appl Polym Sci 105:2036

Li ZH, Zhang J, Chen SJ (2008) Express Polym Lett 2:695

Wu Y-T, Stewart MA (2010) Ethylene acrylic elastomers. Encyclopedia of polymer science and technology. Interscience Wiley, New York

Karasek L, Sumita M (1996) J Mater Sci 31:281. doi: 10.1007/BF01139141

Flory PJ, Rehner J (1943) J Chem Phys 11:512

Huggins ML (1941) J Chem Phys 9:40

Flory PJ (1941) J Chem Phys 9:660

Kraus G (1963) J Appl Polym Sci 7:861

Sridhar V, Gupta BR, Tripathy DK (2006) J Appl Polym Sci 10:715

Roychoudhury A, De PP, Dutta NK, Choudhury N, Roychoydhury N, Haidar B, Vidal A (1993) Rubber Chem Technol 66:230

Wolff S, Wang MJ (1992) Rubber Chem Technol 65:329

Banik I, Bhowmick AK (2000) J Appl Polym Sci 76:2061

Choi SS, Nah C, Jo BW (2003) Polym Int 52:1382

Fukumori K, Kurauchi T, Kamigato O (1990) Polymer 31:713

Kader MA, Bhowmick AK (2003) J Appl Polym Sci 89:1442

Zhang J, Feng S, Ma Q (2003) J Appl Polym Sci 89:1548

López-Manchado MA, Biagiotti J, Valentini L, Kenny JM (2004) J Appl Polym Sci 92:3394

Psarras C, Manolakaki E, Tsangaris GM (2002) Composites 33:375

Ku CC, Liepins R (1987) Chemical principles. Hanser Publishers, Munich

Yuan Q, Wu D (2010) J Appl Polym Sci 115:3527

Li J, Kim J-K (2007) Compos Sci Technol 67:2114

Jäger K-M, McQueen DH, Tchmutin IA, Ryvkina NG, Klüppel M (2001) J Phys 34:2699

Datta S, De SK, Kontos EG, Wefer JM, Wagner P, Vidal A (1996) Polymer 37:3431

Patra A, Bisoyi DK (2010) J Mater Sci 45:5742. doi: 10.1007/s10853-010-4644-8

Xi Y, Bin Y, Chiang CK, Matsuo M (2007) Carbon 45:1302

Lvovich VF, Smiechowski MF (2005) J Electroanal Chem 577:67

Colarnerr NF, Saha TN (1992) IEEE Trans Instrum 41:291

Das NC, Khastgir D, Chaki TK, Chakraborty A (2000) Composites 31:1069

Ye L, Zhang Y, Wang Z (2007) J Appl Polym Sci 105:3851

Acknowledgement

The authors would like to gratefully acknowledge the financial assistance supported by the Board of Research in Nuclear Sciences (BRNS), India to carry out the research work. Contract grant sponsor: Board of Research in Nuclear Sciences (BRNS), Department of Atomic Energy (DAE), Mumbai, India; contract grant number: 2008/35/8/BRNS/3096 dated 23/03/2009

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sahoo, B.P., Naskar, K. & Tripathy, D.K. Conductive carbon black-filled ethylene acrylic elastomer vulcanizates: physico-mechanical, thermal, and electrical properties. J Mater Sci 47, 2421–2433 (2012). https://doi.org/10.1007/s10853-011-6065-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-6065-8