Abstract

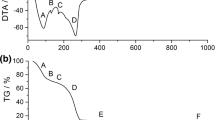

This article addresses the growth of hollow nanocrystalline particles of γ-alumina by the post-oxidation of nano-aluminium particles in air. The nanoparticles of aluminium were synthesized in a DC-transferred arc thermal plasma reactor. The as-synthesized nano-aluminium particles were oxidized, in air, at different temperatures. The as-synthesized parent nano aluminium and their daughter nanoparticles of aluminium oxide were thoroughly characterized with the help of X-ray diffraction analysis, high resolution transmission electron microscopy and thermogravimetric analysis. Two-step oxidation behaviours, unique in nanoparticles, are found to be the main driving force behind the formation of hollow spherical structures. The entire phenomenon is compared with the oxidation behaviour of coarse grain aluminium. The content of γ-alumina, identified by X-ray diffraction, relative to that of unreacted aluminium, has increased almost exponentially with the oxidation temperature in the case of nano aluminium. Similar behaviour is not observed in the case of coarse grain aluminium. The crystalline features of alumina, forming the walls of the hollow sphere, were confirmed by high resolution transmission electron microscopy.

Similar content being viewed by others

References

Ichinose N, Ozaki Y, Kashu S, James M (1992) Superfine particle technology. Springer, London

Andrievski RA (1994) J Mater Sci 29:614. doi:10.1007/BF00445970

Gleiter H (1989) Prog Mater Sci 33:223

Krell A, Blank P (1995) J Am Cerm Soc 78:1118

Huinan L, Webster TS (2007) Proceeding of bioengineering conference, IEEE 33rd Annual Northeast

Vassen R (1999) CFI Ceram Forum Int 76:19

Ratnasamy P, Sivsankar S (1980) Catal Rev Sci Eng 22:401

Furmsky E (1980) Catal Rev Sci Eng 22:371

Ciapetta FG, Wallace DN (1972) Catal Rev Sci Eng 5:67

Levin I, Brandon D (1998) J Am Cerm Soc 81:1995

Hirayama T (1976) J Am Ceram Soc 70:C122

Gribb AA, Banfield JF (1997) Am Miner 82:717

Borsella E, Botti S, Giorgi R, Martelli S, Turtu S, Zappa G (1993) Appl Phys Lett 63:1345

Nakajima H, Nakamura R (2010) Mater Sci Forum 638–642:67

Nanoko M, Matsumaru K, Ishizaki K (2006) Azojomo 2:1

Eun TH, Kim SH, Jeong WJ, Jeon SJ, Kim SH, Yang SM (2009) Chem Mater 21:201

Lee CW, Lee JS (2006) J Cerm Soc Jpn 114:923

Li XL, Lou TJ, Sun XM, Li YD (2004) Inorg Chem 43:5442

Guo XF, Kim YS, Kim GJ (2009) J Phys Chem C 113:8313

Kou H, Wang J, Pan Y, Guo J (2005) J Am Cerm Soc 88:1615

Cao F, Li DX (2009) Biomed Mater 4:025009 6pp

Pravdic G, Gani MSJ (1996) J Mater Sci 31:3487. doi:10.1007/BF00360753

Kulkarni NV, Karmakar S, Banerjee I, Sahasrabudhe SN, Das AK, Bhoraskar SV (2009) Met ResBull 44:581

JCPDS data: c-Aluminium [4–787], γ-Al2O3 [10–425]

Whiston C. X-ray methods, India edition (2008) Wiley India, New Delhi

Toraya H, Yoshimura M, Somiya S (1984) J Am Ceram Soc 67:C119

Wu NL, Wu TF (2000) J Am Ceram Soc 83:3225

Il’in AP, Gromov AA, Yablunovskii GV (2001) Comb Expl Shock Waves 37:418

Park K, Lee D, Rai A, Mukherjee D, Zachariah MR (2005) J Phys Chem B 109:7290

Pivkina A, Streletskii A, Kolbanev I, Ul’yanova P, Frolov Yu, Butyagin P (2004) J Mater Sci 39:5451. doi:10.1023/B:JMSC.0000039264.33941.82

Ramaswamy AL, Kaste P (2005) J Energ Mater 23:1

Iijima SJ (1987) Appl Phys 26:357

Iijima SJ (1987) J Appl Phys 26:365

Sako S, Ohshima K, Fujita T (1990) J Phys Soc Jpn 59:662

Cabrera N, Mott NF (1948) Rep Prog Phys 12:163

Campbell T, Kalia RK, Nakano A, Vashishta P, Ogata S, Rodgers S (1999) Phys Rev Lett 82:4866

Rai A, Lee D, Park K, Zachariah MR (2004) J Phys Chem B 108:14793

Acknowledgements

The authors extend their thanks to ARMREB (India) for funding the project. S V. Bhoraskar acknowledges CSIR (India) for granting her the ES Scheme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kulkarni, N.V., Karmakar, S., Asthana, S.N. et al. Study on growth of hollow nanoparticles of alumina. J Mater Sci 46, 2212–2220 (2011). https://doi.org/10.1007/s10853-010-5059-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-5059-2