Abstract

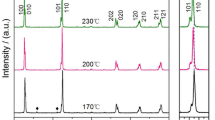

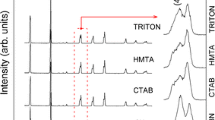

Crystalline lead-free piezoelectric potassium niobate (KNbO3) powders have been synthesized through a modified solid-state reaction method. The thermal behavior of the K2C2O4·H2O and Nb2O5 raw material mixture was investigated by thermogravimetric analysis (TGA) and differential thermal analysis (DTA). The X-ray diffraction technique (XRD) was used to investigate the phase formation and purity. The morphology of the powder obtained was characterized using a scanning electron microscope (SEM). The XRD pattern showed that the monophasic perovskite phase of KNbO3 could be synthesized successfully at a temperature as low as 550 °C for 240 min, with an average crystallite size of 36 ± 8 nm. The SEM images suggested that the average particle size of the powder obtained was 278 ± 75 nm.

Similar content being viewed by others

References

Miclea C, Tanasoiu C, Miclea CF, Amarande L, Gheorghiu A, Spanulescu I, Plavitu C, Miclea CT, Cioangher MC, Trupina L, Iuga A (2007) J Eur Ceram Soc 27:4055

Setter N (2002) Piezoelectric materials in devices. Ceramic lab, EPFL, Switzerland

Lead and you: a guide to working safely with lead (2003) HSE (UK Health and Safety Executive). http://www.hse.gov.uk/pubns/indg305.pdf. Accessed 25 Apr 2004

Commission of the European Communities (2003) Directive 2002/96/EC of the European Parliament and of the Council of 27 January 2003 on waste electrical and electronic equipment (WEEE). Off J Eur Union, L37, 46:24

Commission of the European Communities (2003) Directive 2002/95/EC of the European Parliament and of the Council of 27 January 2003 on the restriction of the use of certain hazardous substances in electrical and electronic equipment. Off J Eur Union, L37, 46:19

Ichiki M, Zhang L, Tanaka M, Maeda R (2004) J Eur Ceram Soc 24:1693

Liu J-F, Li X-L, Li Y-D (2003) J Cryst Growth 247:419

Paula AJ, Parra R, Zaghete MA, Varela JA (2008) Mater Lett 62:2581

Yamanouchi K, Odagawa H, Kojima T, Matsumura T (1997) Electron Lett 33:193

Nakamura K, Kawamura Y (1999) Proc IEEE Ultrason Symp 2:1013

Matsumoto K, Hiruma Y, Nagata H, Takenaka T (2008) Ceram Int 34:787

Makovec D, Pribošič I, Drofenik M (2008) Ceram Int 34:89

Lu CH, Lo SY, Lin HC (1998) Mater Lett 34:172

Muthurajan H, Kumar HH, Samuel V, Gupta UN, Ravi V (2008) Ceram Int 34:671

Kim MS, Lee DS, Park EC, Jeong SJ, Song JS (2007) J Eur Ceram Soc 27:4121

Mgbemere HE, Herber R-P, Schneider GA (2009) J Eur Ceram Soc 29:1729

Wang R, Xie R, Sekiya T, Shimojo Y, Akimune Y, Hirosaki N, Itoh M (2002) Jpn J Appl Phys 41:7119

Ahn ZS, Schulze WA (1987) J Am Ceram Soc 70:18

Jaeger RE, Egerton L (1962) J Am Ceram Soc 45:209

Chang Y, Yang Z, Wei L, Liu B (2006) Mater Sci Eng A 437:301

Bhattacharyya K, Tyagi AK (2009) J Alloys Compd 470:580

Amini MM, Mirzaee M (2009) Ceram Int 35:2367

Lu C-H, Lo S-Y, Wang Y-L (2002) Mater Lett 55:121

Xu J, Xue D, Yan C (2005) Mater Lett 59:2920

Chaiyo N, Boonchom B, Vittayakorn N (2010) J Mater Sci 45:1443. doi:10.1007/s10853-009-4098-z

Vlaev L, Nedelchev N, Gyurova K, Zagorcheva M (2008) J Anal Appl Pyrolysis 81:253

Hsiao Y-J, Chang Y-H, Chang Y-S, Fang T-H, Chai Y-L, Chem G-J, Huang T-W (2007) Mater Sci Eng B 136:129

Callister WD (2007) Materials science and engineering: an introduction. Wiley, New York

Pribošič I, Makovec D, Drofenik M (2005) J Eur Ceram Soc 25:2713

Kakimoto K, Ito T, Ohsato H (2008) Jpn J Appl Phys 47:7669

Malic B, Bernard J, Bencan A, Kosec M (2008) J Eur Ceram Soc 28:1191

Chang Y, Yang Z-P, Ma D, Liu Z, Wang Z (2008) J Appl Phys 104:024109

Amini MM, Sacks MD (1991) J Am Ceram Soc 74:53

Kim KJ, Matijevic E (1992) J Mater Res 7:912

Klug HP, Alexander LE (1974) X-ray diffraction procedure of polycrystalline and amorphous materials. Wiley, New York

Lanfredi S, Dessemond L, Rodrigue ACM (2000) J Eur Ceram Soc 20:983

de Andrade JS, Pinheiro AG, Vasconcelos IF et al (1999) J Phys Condens Matter 11:4451

Böke HA, Akkurt S, Özdemir S, Göktürk EH, Saltik ENC (2004) Mater Lett 58:723

Terashi Y, Purwanto A, Wang WN, Iskandar F, Okuyama K (2008) J Eur Ceram Soc 28:2573

Wongmaneerung R, Chaisan W, Khamman O, Yimnirun R, Ananta S (2008) Ceram Int 34:813

Acknowledgements

This study was supported by the Thailand Research Fund (TRF), Thailand Graduate Institute of Science and Technology (TGIST), and the National Nanotechnology Center (NANOTEC) NSTDA, Ministry of Science and Technology, Thailand, through its “Center of Excellence Network” Program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chaiyo, N., Ruangphanit, A., Muanghlua, R. et al. Synthesis of potassium niobate (KNbO3) nano-powder by a modified solid-state reaction. J Mater Sci 46, 1585–1590 (2011). https://doi.org/10.1007/s10853-010-4967-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4967-5