Abstract

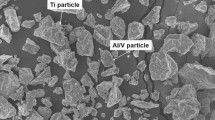

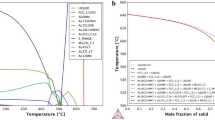

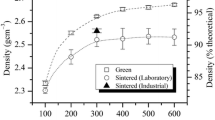

This article reports experimental results on laser sintering of A356 aluminum alloy and A356/SiC composite powders. Effects of scan rate, sintering atmosphere, hatch spacing, and SiC volume fraction (up to 20%), and particle size (7 and 17 μm) on the densification were studied. The phase formation and microstructural development were analyzed by X-ray diffraction (XRD) and scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS). Laser sintering under argon atmosphere exhibited higher densification compared to nitrogen. A faster sintering kinetics was observed as the scan rate decreased. Except at a low SiC content (5 vol%), the composite powders exhibited lower densification kinetics. The densification was improved when finer SiC particles were utilized. Microstructural studies revealed directional solidification of aluminum melt to form columnar grains with inter-columnar silicon precipitates. In the presence of SiC particles, aluminum melt reacted with the ceramic particles to form Al4SiC4 plates.

Similar content being viewed by others

References

Simchi A (2006) Mater Sci Eng 428A:148

Simchi A (2004) Metall Mater Trans 35B:937

Traini T, Mangano C, Sammons RL, Mangano F, Macchi A, Piattelli A (2008) Dent Mater 24:1525

Gu DD, Shen YF (2006) Metall Mater Trans 37B:967

Fischer P, Romano V, Weber HP, Kolossov S (2004) Thin Solid Films 453–454:139

Kruth JP, Froyen L, Rombouts M, Van Vaerenbergh J, Mercells P (2003) CIRP Ann Manuf Technol 52:139

Simchi A, Petzoldt F, Pohl H (2001) Int J Powder Metall 37:49

Liu DM, Si TZ, Wang CC, Zhang QA (2007) Scripta Mater 57:389

Gu DD, Shen YF (2006) Mater Sci Eng A435–436:54

Gåård A, Krakhmalev P, Bergström J (2006) J Alloy Compd 421:166

Leong CC, Lu L, Fuh JYH, Wong YS (2002) Mater Sci Eng A338:81

Tan KH, Chua CK, Leong KF, Cheah CM, Cheang P, Abu Bakar MS, Cha SW (2003) Biomaterials 24:3115

Shishkovsky I, Yadroitsev I, Bertrand Ph, Smurov I (2007) Appl Surf Sci 254:966

Ramesha CS, Srinivas CK, Channabasappa BH (2009) Wear 267:1777

Vaucher S, Paraschivescu D, Andre C, Beffort O (2002) In: Materials week, 30.09.–2.10.2002, ICM-Munich, ISBN: 3-88355-314-X

Simchi A, Godlinski D (2008) Scripta Mater 59:199

Viala JC, Fortier P, Bouix J (1990) J Mater Sci 25:1842. doi:10.1007/BF01045395

Gacsi Z, Kovacs J, Pieczonka T, Buza G (2002) Surf Coat Technol 151–152:320

Kurtz W, Fischer DJ (1992) Fundamentals of solidification. Trans. Tech. Publications, Aedermannsdorf, Switzerland

Grabowski A, Nowak M, Sleziona J (2005) Opt Lasers Eng 43:233

Anandkumar R, Almeida A, Colaço R, Vilar R, Ocelik V, De Hosson J, Th M (2007) Surf Coat Technol 201:9497

Lee J-C, Byun J-Y, Oh C-S, Sek H-K, Lee H-I (1997) Acta Mater 45:5303

Acknowledgement

Partial funding of this work by the European Commission within the Network of Excellence “Knowledge-based multicomponent materials for durable and safe performance” (KMM-NoE) is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Simchi, A., Godlinski, D. Densification and microstructural evolution during laser sintering of A356/SiC composite powders. J Mater Sci 46, 1446–1454 (2011). https://doi.org/10.1007/s10853-010-4943-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4943-0