Abstract

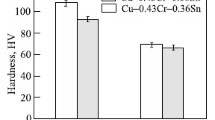

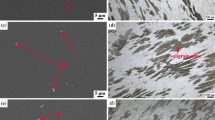

The effect of aluminum on the precipitation hardening of Cu–Ni–Zn alloys with varying aging temperatures and times was investigated in this article, in the hope to achieve better mechanical properties. Vickers hardness, tensile, and electrical conductivity tests were carried out to characterize the properties of the Cu–Ni–Zn alloys with or without an addition of aluminum subjected to different aging treatments. The results show that an addition of 1.2 wt% aluminum can play an influential role in the precipitation hardening of the Cu–Ni–Zn alloys. For example, it can increase the peak hardness from 58 Hv for the solution-treated Cu–10Ni–20Zn alloy to 185 Hv for the solution-treated Cu–10Ni–20Zn–1.2Al alloy during aging at 500 °C. The yield strength, tensile strength, and electrical conductivity of the Cu–10Ni–20Zn–1.2Al alloy subjected to suitable treatments under prior cold-rolled and aged conditions can reach 889 MPa, 918 MPa, and 10.96% IACS, respectively, being much higher than those of the relevant alloy without aluminum and comparable to those of the Cu–Be alloys (C17200 and C17510). According to the transmission electron microscope observations, it was found that formation of nanosized precipitates with the L12-type ordered lattice results in precipitation hardening, and an orientation relationship of \( [011]_{\text{p}}//[011]_{\text{m}} \) and \( (100)_{\text{p}}//(200)_{\text{m}} \) exists between the precipitates and the α-Cu matrix.

Similar content being viewed by others

References

Metals handbook, properties and selection: non-ferrous alloys and special purpose materials, vol 2, 10th edn. ASM International, Metals Park, OH, 1990

Nagarjuna S, Srinivas M, Sharma KK (2000) Acta Mater 48:1807

Sierpiński Z, Gryziecki J (1999) Mater Sci Eng A 264:279

Cho Y-R, Kim Y-H, Lee TD (1991) J Mater Sci 26:2879. doi:10.1007/BF01124816

Zelaya E, Tolley A, Condó AM, Fichtner PFP (2007) Mater Sci Eng A 444:178

Zelaya E, Tolley A (2003) Scripta Mater 49:373

Lelatko J, Morawiec H (1996) J Mater Sci 31:2767. doi:10.1007/BF00687313

Murray JL (1997) In: Baker H, Okamoto H (eds) Alloy phase diagrams, ASM handbook. ASM International, Materials Park, OH, p 3.12

Dutta B, Pamiere EJ, Sellars CM (2001) Acta Mater 49:785

Nagarjuna S, Balabubramanian K, Sarma DS (1999) J Mater Sci 34:2929. doi:10.1023/A:1004603906359

Gorelik SS (1981) Recrystallization in metals and alloys. Mir publishers, Moscow, pp 379–413

Ungár T, Borbély A (1996) Appl Phys Lett 69:3173

Stranik MJ, Wang SC (2003) Acta Mater 51:5131

Čížek J, Procházka I, Smola B, Stulíková I, Očenášek V (2007) J Alloy Compd 430:92

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, XZ., Su, YC. & Sun, JM. Effect of aluminum on precipitation hardening in Cu–Ni–Zn alloys. J Mater Sci 45, 3080–3087 (2010). https://doi.org/10.1007/s10853-010-4315-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4315-9