Abstract

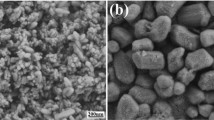

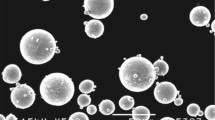

Thermal spray represents an advantageous technique for depositing large-area titanium dioxide coatings that are of interest for both traditional wear-resistant coatings as well as functional applications such as photo-induced decontamination surfaces. Numerous past studies have examined the phase evolution and properties of TiO2 coatings using different thermal spray processes or parameters. In this paper, an integrated study of thermal sprayed TiO2 was conducted with different thermal spray devices and process parameters for a single feedstock powder comprising the metastable anatase phase. The aforementioned variables are correlated with in-flight particle state (particle temperature and velocity), phase evolution, and coating physical properties. The results are represented through the framework of process maps which connect process parameters with material properties. Based on the phase characterization, an initial exploration of the metastable phase evolution during thermal spray deposition of TiO2 is proposed. Furthermore, the sprayed TiO2 coatings show varying degrees of electrical conductivity associated with process-induced stoichiometric changes (vacancy generation) in the TiO2. The effects of these stoichiometric changes as well as extrinsic microstructural attributes (pores, cracks, interfaces), contribute to the complex electrical response of the coatings. This integrated study provides insights into the process–microstructure–property relationship with the ultimate goal of tailoring the functionality of spray deposited oxide thick films.

Similar content being viewed by others

References

Diebold U (2003) Surf Sci Rep 48:53

Fujishima A, Rao TN, Tryk DA (2000) J Photochem Photobiol C Photochem Rev 1:1

Hashimoto K, Kawai T, Sakata T (1984) J Phys Chem 88(18):4083

Anpo M, Aikawa N, Kubokawa Y, Che M, Louis C, Giamello E (1985) J Phys Chem 89:5689

Logothetis E (1980) In: Ceramic engineering and science proceedings, p 1

Yan MF, Rhodes WW (1982) Appl Phys Lett 40:536

Campbell SA, Kim H-S, Gilmer DC, He B (1999) IBM J Res Dev 43

Lee C, Choi H, Lee C, Kim H (2003) Surf Coat Technol 173:192

Lima R, Marple B, Li H, Khor K (2006) J Therm Spray Technol 15:623

Ohsaki H, Tachibana Y, Hayashi A, Mitsui A, Hayashi Y (1999) Thin Solid Films 351:57

Ye F, Ohmori A (2002) Surf Coat Technol 160:62

Lima R, Marple B (2003) J Therm Spray Technol 12:360

Toma F-L, Sokolov D, Bertrand G, Klein D, Coddet C, Meunier C (2006) J Therm Spray Technol 15:576

Bertrand G, Berger-Keller N, Meunier C, Coddet C (2006) Surf Coat Technol 200:5013

Lima R, Marple B (2003) J Therm Spray Technol 12:240

Wang XY, Liu Z, Liao H, Klein D, Coddet C (2005) Thin Solid Films 473:177

Li Y, Ishigaki T (2002) J Cryst Growth 242:511

Sclafani A, Herrmann JM (1996) J Phys Chem 100:13655

Bach FW, Mohwald K, Rothardt T, Prehm J, Engl L, Hartz K, Droler B (2004) Mater Sci Eng A 383:146

Sun J, Gao L, Zhang Q (2003) J Am Ceram Soc 86:1677

Wang Z, Kulkarni A, Deshpande S, Nakamura T, Herman H (2003) Acta Mater 51:5319

Swindeman CJ, Seals RD, Murray WP, Cooper MH, Forbes KR (1995) An investigation of thermally-sprayed aluminum oxide coatings for high-temperature electrostatic chucks (ESCs). In: Semiconductor manufacturing, IEEE/UCS/SEMI international symposium, Institute of Electrical and Electronics Engineers, Austin, TX, USA, 1995

Xiong H-B, Zheng L-L, Li L, Vaidya A (2005) Int J Heat Mass Transfer 48:5121

Branland N, Meillot E, Fauchais P, Vardelle A, Gitzhofer F, Boulos M (2006) J Therm Spray Technol 15:53

Sharma A (2006) Anisotropic electrical properties of thermal spray coatings: the role of splat boundary interfaces. Doctoral Dissertation, Stony Brook University, 163 pp

Sampath S, Jiang X, Kulkarni A, Matejicek J, Gilmore DL, Neiser RA (2003) Mater Sci Eng A 348:54

Turunen E, Varis T, Hannula SP, Vaidya A, Kulkarni A, Gutleber J, Sampath S, Herman H (2006) Mater Sci Eng A 415:1

Vaidya A, Srinivasan V, Streibl T, Friis M, Chi W, Sampath S (2008) Mater Sci Eng A 497(1–2):239

Planche MP, Coudert JF, Fauchais P (1998) Plasma Chem Plasma Process 18:263

Zhang W, Zheng L, Zhang H, Sampath S (2007) Plasma Chem Plasma Process 27(6):701

Srinivasan V, Vaidya A, Streibl T, Friis M, Sampath S (2006) J Therm Spray Technol 15:739

Srinivasan V, Friis M, Vaidya A, Streibl T, Sampath S (2007) Plasma Chem Plasma Process 27:609

Burlacov I, Jirkovsky J, Muller M, Heimann RB (2006) Surf Coat Technol 201:255

Li JF, Ding CX (1998) J Mater Sci Lett 17:1747

McPherson R (1984) Thin Solid Films 112:89

Cowan RD (1963) J Appl Phys 34:926

Degiovanni A, Laurent M (1986) Rev Phys Appl 21:229

Vardelle M, Vardelle A, Leger A, Fauchais P, Gobin D (1995) J Therm Spray Technol 4:50

Fauchais P (1995) J Therm Spray Technol 4:3

Sampath S, Herman H (1996) J Therm Spray Technol 5:445

Lee E-A, Lee S-W, Choi C-H, Kim H-S, Hockey B (2003) Mater Sci Forum 439:8

Li L, Kharas B, Zhang H, Sampath S (2007) Mater Sci Eng A 456:35

Safai S (1979) In: Materials science and engineering, Stony Brook University, Stony Brook, p 250

Sharma A, Gouldstone A, Sampath S, Gambino R (2006) J Appl Phys 100:114906

Cronemeyer DC (1952) Phys Rev 87:876

Chiang Y-M, Birnie D, Kingery WD (1997) Physical ceramics: principles for ceramics science and engineering. Wiley, New York

Acknowledgements

This research was supported by the National Science Foundation through the GOALI-FRG program supported jointly by the Division of Materials Research and the Division of Materials Processing and Manufacturing under award CMMI 0605704. Prof. Cannillo and the University of Modena Team acknowledge support of MIUR, Italy (Programmi per l’incentivazione del processo di internazionalizzazione del sistema universitario).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Colmenares-Angulo, J.R., Cannillo, V., Lusvarghi, L. et al. Role of process type and process conditions on phase content and physical properties of thermal sprayed TiO2 coatings. J Mater Sci 44, 2276–2287 (2009). https://doi.org/10.1007/s10853-008-3044-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3044-9