Abstract

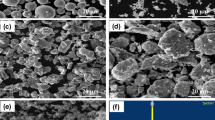

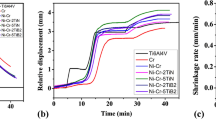

Titanium boride (TiBw) whiskers are currently recognized as one of the most compatible reinforcements for titanium (Ti) that have positively affected its wear resistance and stiffness. The fracture toughness and ductility have, however, been reported to deteriorate at increased TiBw volume fractions, mainly due to the interlocking of these brittle TiB whiskers. This article investigates the processing of dual matrix Ti–TiBw composites, where microstructures are generated consisting of TiBw–Ti composite regions separated by a ductile, predominantly Ti, outer matrix. This microstructural design has the potential to prevent the continuous TiBw interlocking over the scale of the composite (at high TiBw volume fractions), and promote improved toughness of the material. The processing of these unique composites using current-activated pressure-assisted sintering (CAPAS) is discussed in this article. The effect of processing temperature on the microstructure and hardness of Ti–TiBw dual matrix composites is also discussed, together with a simultaneous imaging and modulus-mapping nanoindentation technique used to characterize the composites

Similar content being viewed by others

References

Gorsse S, Chaminade JP, Petitcorps YL (1998) Composites Part A 29(A):1229

Morsi K, Patel VV (2007) J Mater Sci 42:2037

Banerjee R, Collins PC, Fraser HL (2002) Adv Eng Mater 4(11):847

Nardone VC, Strife JR, Prewo KM (1991) Metal Mater Trans 22A:171

Deng X, Patterson BR, Chawla KK, Koopman MC, Fang Z, Lockwood G, Griffo A (2001) Int J Refractory Metals Hard Mater 19:547

Deng X, Patterson BR, Chawla KK, Koopman MC, Mackin C, Fang Z, Lockwood G, Griffo A (2002) J Mater Sci Lett 21:707

Fang Z, Lockwood G, Griffo A (1999) Metal Mater Trans 30A:3231

Morsi K, Patel VV, Naraghi S, Garay JE (2008) J Mater Process Technol 196(1):236

Munir ZA, Anselmi-Tamburini U, Ohyanagi M (2006) J Mater Sci 41:763

Anselmi-Tamburini U, Garay JE, Munir ZA (2005) Mater Sci Eng A 407:24

Garay JE, Anselmi-Tamburini U, Munir ZA (2003) Acta Mater 51:4487

Garay JE, Glade SC, Anselmi-Tamburini U, Asoka-Kumar P, Munir ZA (2004) Appl Phys Lett 85(4):573

Wang X, Casolco SR, Xu G, Garay JE (2007) Acta Mater 55:3611

Feng H, Zhou Y, Jia D, Meng Q (2004) Compos Sci Technol 64(16):2495

Feng H, Jia D, Zhou Y (2005) Composites: Part A 36:558

Panda KB, Ravi Chandran KS (2003) Metal Mater Trans 34A(6):1371

Stephen AJ, Houston JE (1991) Rev Sci Instrum 62(3):710

Pethica JB, Oliver WC (1987) Phys Scr T19A:61

Syed Asif SA, Wahl KJ, Colton RJ (1999) Rev Sci Instrum 70(5):2408

Oliver WC, Pharr GM (1992) J Mater Res 7(6):1564

Uskokovic PS, Tang CY, Tsui CP, Ignjatovic N, Uskokovic DP (2007) J Eur Ceram Soc 27(2–3):1559

Moon KS, Morsi K, Hong YK (2007) Int J Optomechatron 1:1

Chakravartula A, Komvopoulos K (2006) Appl Phys Lett 88:131901

Gorsse S, Miracle DB (2003) Acta Mater 51:2427

Acknowledgements

The authors would like to thank Dr. Steve Barlow for his help with electron microscopy, and Mr. Greg Morris and Mr. Michael Lester for their technical assistance throughout this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Morsi, K., Patel, V.V., Moon, K.S. et al. Current-activated pressure-assisted sintering (CAPAS) and nanoindentation mapping of dual matrix composites. J Mater Sci 43, 4050–4056 (2008). https://doi.org/10.1007/s10853-007-2225-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2225-2