Abstract

The processing quality of the grooves of a nuclear-fuel rod will directly affect the quality of the finished nuclear-fuel rod. Due to the highly reflective, microscopic, and annular characteristics of nuclear-fuel rod grooves, it has been quite challenging to realize imaging and microscopic defect detection for these grooves. In this work, a machine vision-based defect detection system was developed for nuclear-fuel rod grooves. Through the performance improvement and application of the self-reference template defect detection method, efficient online inspection of nuclear-fuel rod grooves was realized. In the developed system, a combined-light-source imaging system was first designed by combining a coaxial light and a ring light, which realized the clear imaging of a groove. After that, an image expansion strategy was employed to expand the annular groove into a strip-shaped region of interest (ROI). Then, according to the turning processing characteristic of the nuclear-fuel rod groove, the large-size defect detection effect of the self-reference template method was improved by eliminating the anomalous columns prior to generating the self-reference template. The experimental results indicated that the average inspection efficiency of the developed system was 8.026 s/rod, the average false detection rate was 0.183%. The accuracy of the self-reference template method was 87.6%, higher than that of YOLOv2 and Faster R-CNN. The developed system exhibits high inspection efficiency and accuracy, so it can meet the actual detection functions and requirements of production lines, and now it has been successfully applied to actual production.

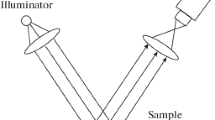

source imaging system: a overall appearance of the imaging system, b internal details of the imaging system

Similar content being viewed by others

References

Badmos, O., Kopp, A., Bernthaler, T., et al. (2020). Image-based defect detection in lithium-ion battery electrode using convolutional neural networks. Journal of Intelligent Manufacturing, 31, 885–897. https://doi.org/10.1007/s10845-019-01484-x.

Boby, R. A., Sonakar, P. S., Singaperumal, M., & Ramamoorthy, B. (2011). Identification of defects on highly reflective ring components and analysis using machine vision. International Journal of Advanced Manufacturing Technology, 52(1), 217–233. https://doi.org/10.1007/s00170-010-2730-3.

Butler, D. (2011). Nuclear safety: Reactors, residents and risk. Nature, 472(7344), 400–401. https://doi.org/10.1038/472400a.

Cao, J., Cheng, Y., Wang, P., et al. (2016). Method based on bioinspired sample improves autofocusing performances. Optical Engineering, 55(10), 103103. https://doi.org/10.1117/1.OE.55.10.103103.

Carrera, D., Manganini, F., Boracchi, G., et al. (2017). Defect Detection in SEM Images of Nanofibrous Materials. IEEE Transactions on Industrial Informatics, 13(2), 551–561. https://doi.org/10.1109/TII.2016.2641472.

Chan, C. H., & Pang, G. K. H. (2000). Fabric defect detection by Fourier analysis. IEEE Transactions on Industry Applications, 36(5), 1267–1276. https://doi.org/10.1109/28.871274.

Chen, S., Liu, J., Zhang, X., et al. (2020). Development of positioning system for Nuclear-fuel rod automated assembly. Robotics and Computer-Integrated Manufacturing, 61, 101826. https://doi.org/10.1016/j.rcim.2019.101826.

Dom, B. E., Brecher, V. H., Bonner, R., et al. (1988). The P300: A system for automatic patterned wafer inspection. Machine Vision and Applications, 1(4), 205–221. https://doi.org/10.1007/BF01212360.

Gao G, Wu X (2013). Light optimal design for machine vision based on reflection. 2013 IEEE International Conference on Information and Automation (ICIA). IEEE. https://doi.org/https://doi.org/10.1109/ICInfA.2013.6720293

Jing, J. F., Chen, S., & Li, P. F. (2016). Fabric defect detection based on golden image subtraction. Coloration Technology. https://doi.org/10.1111/cote.12239.

Joshi, K. D., Vedang, C., & Brian, S. (2018). A flexible machine vision system for small part inspection based on a hybrid svm/ann approach. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-018-1438-3.

Kong, H., Yang, J., & Chen, Z. (2017). Accurate and Efficient Inspection of Speckle and Scratch Defects on Surfaces of Planar Products. IEEE Transactions on Industrial Informatics, 13(4), 1855–1865. https://doi.org/10.1109/TII.2017.2668438.

Li, D., Wang, S., & Fu, Y. (2017). Quality detection system and method of micro-accessory based on microscopic vision. Modern Physics Letters B. https://doi.org/10.1142/S0217984917502700.

Liu, R., Sun, Z., Wang, A., et al. (2020). Real-time defect detection network for polarizer based on deep learning. Journal of Intelligent Manufacturing, 31, 1813–1823. https://doi.org/10.1007/s10845-020-01536-7.

Prats-Montalbán, J. M., & Ferrer, A. (2014). Statistical process control based on Multivariate Image Analysis: A new proposal for monitoring and defect detection. Computers & Chemical Engineering, 71, 501–511. https://doi.org/10.1016/j.compchemeng.2014.09.014.

Rodriguez, A., Val, C. G., Fernandez, A., Rodriguez, F., & Bellman, M. (2020). Automatic solar cell diagnosis and treatment. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-020-01642-6.

Rong, Y., & Liang, X. S. (2018). A Study of the Impact of the Fukushima Nuclear Leak on East China Coastal Regions. Atmosphere-Ocean, 56(4), 1–14. https://doi.org/10.1080/07055900.2017.1421139.

Shankar, N. G., & Zhong, Z. W. (2005). Defect detection on semiconductor wafer surfaces. Microelectronic Engineering, 77(3/4), 337–346. https://doi.org/10.1016/j.mee.2004.12.003.

Sun, T. H., Tien, F. C., Tien, F. C., et al. (2016). Automated thermal fuse inspection using machine vision and artificial neural networks. Journal of Intelligent Manufacturing, 27(3), 639–651. https://doi.org/10.1007/s10845-014-0902-y.

Tae-Hyung, N., Suck-Joo, N., & Young-Whan, P. (2018). A study on characteristics of end plug resistance welding process in nuclear fuel rods by experiment and numerical simulation. The International Journal of Advanced Manufacturing Technology. https://doi.org/10.1007/s00170-018-2365-3.

Tsai, D. M., & Lai, S. C. (2008). Defect detection in periodically patterned surfaces using independent component analysis. Pattern Recognition, 41(9), 2812–2832. https://doi.org/10.1016/j.patcog.2008.02.011.

Xiaojun, W., & Guangming, G. (2018). LED light design method for high contrast and uniform illumination imaging in machine vision. Applied Optics, 57(7), 1694. https://doi.org/10.1364/AO.57.001694.

Xie, L., Lin, L., Yin, M., et al. (2016). A novel surface defect inspection algorithm for magnetic tile. Applied Surface Science, 375, 118–126. https://doi.org/10.1016/j.apsusc.2016.03.013.

Yang, Z., Lu, S., Wu, T., et al. (2018). Detection of morphology defects in pipeline based on 3D active stereo omnidirectional vision sensor. Iet Image Processing, 12(4), 588–595. https://doi.org/10.1049/iet-ipr.2017.0616.

Yun, P. J. (2008). Real-time vision-based defect inspection for high-speed steel products. Optical Engineering, 47(7), 077204. https://doi.org/10.1117/1.2957958.

Yun, P. J. (2009). Vision-based defect detection of scale-covered steel billet surfaces. Optical Engineering, 48(3), 37205. https://doi.org/10.1117/1.3102066.

Acknowledgements

This work is supported by the China-Japan Science and Technology Joint Committee of the Ministry of Science and Technology of the People's Republic of China (Grant No. 2017YFE0128400), the Key Project of Science and Technology of Changsha (Grant No. kq1902049), the Innovation on working methodology of Ministry of Science and Technology of the People's Republic of China (Grant No. 2016IM030300), the Independent research work of State Key Laboratory of Advanced Design and Manufacture for Vehicle Body (Grant No. 71675001), the Foundation for Innovative Research Groups of the National Natural Science Foundation of China (Grant No. 51621004), and the Intelligent Manufacturing Integrated Standardization and New Model Application Project of Minister of Industry and Information Technology of the People's Republic of China (Grant No. 2016ZXFM02016). Also, the authors would like to express their thanks to the reviewers for their valuable suggestions. We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company. The data materials in this paper are all real and available. We will provide the original data and MATLAB original code.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suo, X., Liu, J., Dong, L. et al. A machine vision-based defect detection system for nuclear-fuel rod groove. J Intell Manuf 33, 1649–1663 (2022). https://doi.org/10.1007/s10845-021-01746-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-021-01746-7