Abstract

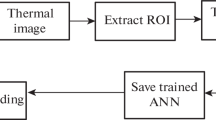

Machine vision is an excellent tool for inspecting a variety of items such as textiles, fruit, printed circuit boards, electrical components, labels, integrated circuits, machine tools, etc. This paper presents an intelligent system that incorporates machine vision with artificial intelligent networks to automatically inspect thermal fuses. An effective inspection flow is proposed to detect four commonly seen defects, including black-dot, small-head, bur, and flake during the production of thermal fuses. Backpropagation neural networks and learning vector quantization performance is compared in detecting the bur defect because of its illegibility. Different numbers of defective samples were screened out from a production line in a case study company and used to demonstrate the efficacy of the proposed system. Currently, the proposed inspection system is operating at the case study company, replacing four to six human inspectors. The system not only ensures the quality of the thermal fuses produced, but also reduced the cost of manual visual inspection.

Similar content being viewed by others

References

Basheer, I. A., & Hajmeer, M. (2000). Artificial neural networks: Fundamentals, computing, design, and application. Journal of Microbiological Methods, 43, 3–31.

Benedek, C., Krammer, O., Janóczki, M., & Jakab, L. (2013). Solder paste scooping detection by multilevel visual inspection of printed circuit boards. IEEE Transactions on Industrial Electronics, 60(6), 2318–2331.

Chang, C. Y., Li, C. H., Chang, Y. C., & Jeng, M. (2011). Wafer defect inspection by neural analysis of region features. Journal of Intelligent Manufacturing, 22(6), 953–964.

Chen, S., Lin, B., Han, X., & Liang, X. (2012). Automated inspection of engineering ceramic grinding surface damage based on image recognition. International Journal of Advanced Manufacturing Technology, 66, 431–443.

Chin, R. T., & Harlow, C. A. (1982). Automated visual inspection: A survey. IEEE Transaction on Pattern Analysis and Machine Intelligence, 4(6), 557–573.

Chin, R. T. (1988). Automated visual inspection: 1981 to 1987. Computer Vision, Graphics, and Image Processing, 41(3), 346–381.

Gan, Y., & Zhao, Q. (2013). An effective defect inspection method for LCD using active contour model. IEEE Transactions on Instrumentation and Measurement, 62(9), 2438–2445.

Ghorai, S., Mukherjee, A., Gangadaran, M., & Dutta, P. K. (2013). Automatic defect detection on hot-rolled flat steel products. IEEE Transactions on Instrumentation and Measurement, 62(3), 612–621.

He, L., Chao, Y., Suzuki, K., & Wu, K. (2009). Fast connected-component labeling. Pattern Recognition, 42(9), 1977–1987.

Kumar, S. (2004). Neural networks—A classroom approach. New York: Tata McGrawHill Publishing.

Lahajnar, F., Bernard, R., Pernus, F., & Kovacic, S. (2002). Machine vision system for inspecting electric plates. Computer in Industry, 47(1), 113–122.

Li, W. C., & Tsai, D. M. (2012). Wavelet-based defect detection in solar wafer images with inhomogeneous texture. Pattern Recognition, 45, 742–756.

Li, X., & Tso, S. K. (2006). Improving automatic detection of defects in castings by applying wavelet technique. IEEE Transactions on Industrial Electronics, 53(6), 1927–1934.

Liang, Y., Gao, J., Jian, C., & Chen, X. (2012). Online visual inspection system for OLED defects. Applied Mechanics and Materials, 241–244, 3153–3158.

Lin, H. D. (2007). Automated visual inspection of ripple defects using wavelet characteristic based multivariate statistical approach. Image and Vision Computing, 25(11), 1785–1801.

Malamas, E. N., Petrakis, E. G. M., Zervakis, M., Petit, L., & Legat, J. D. (2003). A survey on industrial vision systems, applications and tools. Image and Vision Computing, 21(2), 171–188.

Newman, T. S., & Jain, A. K. (1995). A survey of automated visual inspection. Computer Vision and Image Understanding, 61(2), 231–262.

Otsu, N. (1979). A threshold selection method from gray-level histograms. IEEE Transactions on Systems, Man and Cybernetics, 9(1), 62–66.

Prijic, A., Prijic, Z., Pesic, B., Pantic, D., Ristic, S., Macic, D., et al. (2008). Design and optimization of S-type thermal cutoffs. IEEE Transactions on Components and Packaging Technologies, 31(4), 904–912.

Scholz-Reiter, B., Weimer, D., & Thamer, H. (2012). Automated surface inspection of cold-formed micro-parts. CIRP Annals: Manufacturing Technology, 61, 531–534.

Shen, H., Li, S., Gu, D., & Chang, Hongxing. (2012). Bearing defect inspection based on machine vision. Measurement, 45, 719–733.

Steiner, D., & Katz, R. (2007). Measurement techniques for the inspection of porosity flaws on machined surfaces. Journal of Computing and Information Science in Engineering, 7, 85–94.

Su, L., Zha, Z., Lu, X., Shi, T. L., & Liao, G. G. (2013). Using BP network for ultrasonic inspection of flip chip solder joints. Mechanical Systems and Signal Processing, 34, 183–190.

Sun, T. H., Tang, C. H., & Tien, F. C. (2011). Measuring the roundness of silicon wafers using the HJ-PSO algorithm. IEEE Transactions on Semiconductor Manufacturing, 24, 80–88.

Sun, T. H., Tseng, C. C., & Chen, M. S. (2010). Electric contacts inspection using machine vision. Image and Vision Computing, 28(6), 890–901.

Thomas, A. D. H., Rodd, M. G., Hold, J. D., & Neill, C. J. (1995). Real-time industrial visual inspection: A review. Real-Time Image, 1(2), 139–158.

Tien, F. C., Yeh, C. H., & Hsieh, K. H. (2004). Automated visual inspection for microdrills in printed circuit board production. International Journal of Production Research, 15, 2477–2495.

Tolba, A. S. (2011). Fast defect detection in homogeneous flat surface products. Expert Systems with Applications, 38, 12339–12347.

Torres, F., Jiménez, L. M., Candelas, F. A., Azorín, J. M., & Agulló, R. J. (2002). Automatic inspection for phase-shift reflection defects in aluminum web production. Journal of Intelligent Manufacturing, 13(3), 151–156.

Wang, M. J., Wu, W. Y., & Hsu, C. C. (2002). Automated post bonding inspection by using machine vision techniques. International Journal of Production Research, 40(12), 2835–2848.

Wu, W. Y., & Hou, C. C. (2003). Automated metal surface inspection through machine vision. Imaging Science Journal, 51(2), 79–88.

Xie, Y., Ye, Y., Zhang, J., Liu, L., & Liu, L. (2014). A physics-based defects model and inspection algorithm for automatic visual inspection. Optics and Lasers in Engineering, 52, 218–223.

Yamashina, H., & Okumura, S. (1996). A machine vision system for measuring wear and chipping of drilling tools. Journal of Intelligent Manufacturing, 7(4), 319–327.

Zhang, X., Tsang, W.-M., Yamazaki, K., & Mori, M. (2013a). A study on automatic on-machine inspection system for 3D modeling and measurement of cutting tools. Journal of Intelligent Manufacturing, 24(1), 71–86.

Zhang, Z., Wang, Y., & Wang, K. (2013b). Fault diagnosis and prognosis using wavelet packet decomposition, Fourier transform and artificial neural network. Journal of Intelligent Manufacturing, 24, 1213–1227.

Zheng, H., Kong, L. X., & Nahavandi, S. (2002). Automatic inspection of metallic surface defects using genetic algorithms. Journal of Materials Processing Technology, 125–126, 427–433.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, TH., Tien, FC., Tien, FC. et al. Automated thermal fuse inspection using machine vision and artificial neural networks. J Intell Manuf 27, 639–651 (2016). https://doi.org/10.1007/s10845-014-0902-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-014-0902-y