Abstract

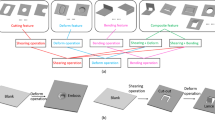

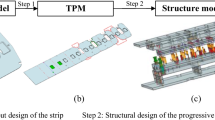

A Progressive die is used to transform flat strips of sheet metal into a formed part. This transformation is performed progressively by a series of stations that stamp the material into a desired shape. The progressive dies reduce the time and cost of producing complex sheet metal components. The design and manufacture of these dies is difficult and complex. Computerized systems have been proved very useful tools for this task. In this paper, a computerized system for the design of the stamping progressive die is presented. In this system, embossing and cutting operations are sequenced based on a classification and fuzzy set theory. The sequencing is done in two stages. First, the operations, which can be carried out simultaneously, are defined by the classification method. In this method, all of the operations are divided into operation groups according to classification rules. Three rules are used to determine the operation groups in this paper. These rules are based on relations between the features in the component. The sequence of the operation groups is then determined using fuzzy set theory. Three components taken from industry are used to show the capabilities of the proposed method.

Similar content being viewed by others

References

Chan, F. T. S., Kumar, V., & Tiwari, M. K. (2009). The relevance of outsourcing and legible strategies in performance optimization of an integrated process planning and scheduling model. International Journal of Production Research, 47(1), 119–142.

Chan, W. L., Fu, M. W., & Lu, J. (2008). An integrated FEM and ANN methodology for metal-formed product design. Engineering Applications of Artificial Intelligence, 21, 1170–1181.

Chang, H., Tsai, Y., & Chiu, K. (2007). A novel optimal working process in the design of parametric progressive dies. Journal of Advanced Manufacturing Technology, 33, 915–928.

Cheok, B. T., & Nee, A. Y. C. (1998). Trends and developments in the automation of design and manufacture of tools for metal stampings. Journal of Materials Processing Technology, 75, 240–252.

Choi, J. C., Kim, B. M., Cho, H. Y., Kim, C., & Kim, J. H. (1998a). An integrated CAD system for the blanking of irregular-shaped sheet metal products. Journal of Materials Processing Technology, 83, 84–97.

Dequan, Y., Rui, Z., Jun, C., & Zhen, Z. (2006). Research of knowledge-based system for stamping process planning. International Journal of Advanced Manufacturing Technology, 29, 663–669.

Duflou, Joost R., Nguyen, T. H. M., Kruth, J. P., & Cattrysse, D. (2005). Automated tool selection for computer-aided process planning in sheet metal bending. CIRP Annals—Manufacturing Technology, 54(1), 451–454.

Farsi, M. A. (2011). A new computerized system for piercing and bending progressive die design. Applied Mechanics and Materials, 110–116, 4823–4831.

Farsi, M. A., & Arezoo, B. (2009). Development of a new method to determine bending sequence in progressive dies. International Journal of Advanced Manufacturing Technology, 43, 52–60.

Fogg, B., & Jaimeson, B. (1975). The influencing factors in optimizing press tool die layout and a solution computer aids. CIRP Annals, 24, 429–434.

Ghatrehnaby, M., & Arezoo, B. (2012). Automatic strip layout design in progressive dies. Journal of Intelligent Manufacturing, 23(3), 661–677.

Giannakakis, T., & Vosniakos, G. C. (2008). Sheet metal cutting and piercing operations planning and tools configuration by an expert system. Journal of Materials Processing Technologies, 36(7–8), 658–670.

Huang, S. H., & Xu, N. (2003). Set-up planning for metal cutting: an integrated methodology. International Journal of Production Research, 41(18), 4339–4356.

Jia, Z.-X., Li, H.-L., Zhang, X.-C., Li, J.-Q., & Chen, B.-J. (2011). Computer-aided structural design of punches and dies for progressive die based on functional component. The International Journal of Advanced Manufacturing Technology, 54, 837–852.

Kim, J. H., Kim, Chul, & Chang, Y. J. (2006). Development of a process sequence determination technique by fuzzy set theory for an electric product with piercing and bending operation. Journal of Advanced Manufacturing Technology, 31, 450–464.

Kumar, S., & Singh, R. (2010). An expert system of design progressive die for using in sheet metal industries. Journal of Scientific and Industrial Research, 96, 510–514.

Nakahara, S., Kojima, T., Tamura, S., Funimo, A., Choichiro, S., & Mukumuru, T. (1978), Computer progressive die design, In Proceedings of 19th MTDR conference, pp. 171–176.

Nee, A. Y. C., & Foong, K. Y. (1992). Some considerations in the design and automatic staging of progressive dies. Journal of Materials Processing Technology, 29(1–3), 147–158.

Ong, S. K., De Vin, L. J., Nee, A. Y. C., & Kals, H. J. J. (1997). Fuzzy set theory applied to bend sequencing for sheet metal bending. Journal of Materials Processing Technology, 79, 29–37.

Ong, S. K., & Nee, A. Y. C. (1994). Application of fuzzy set theory to set-up planning. CIRP Annals, 43(1), 137–143.

Ramana, K. V., & Rao, P. V. M. (2004a). Data and knowledge modeling for design-process planning integration of sheet metal components. Journal of Intelligent Manufacturing, 15, 607–623.

Ramana, K. V., & Rao, P. V. M. (2004b). A system level modeling for sheet metal process planning. In ASME 2004 design engineering technical conferences and computers and information in engineering conference, Salt Lake City, Utah USA, September 28–October 2, 2004.

Ramírez, F. J., Domingo, R., Sebastián, M. A., & Packianather, M. S. (2011). The development of competencies in manufacturing engineering by means of a deep-drawing tool. Journal of Intelligent Manufacturing. doi:10.1007/s10845-011-0575-8.

Schaffer, G. (1971). Computer design of progressive dies. American Machinist, 22, 73–75.

Sitaram, S. K., Kinzel, G. L., & Altan, T. (1991). A knowledge based system for process-sequence design in axisymmentric sheet metal. Journal of Materials Processing Technology, 25, 247–271.

Shi, X., Chen, J., Peng, Y., & Ruan, X. (2002). Development of a knowledge-based process planning system for an auto panel. The International Journal of Advanced Manufacturing Technology, 19, 898–904.

Shibata, Y., & Konimoto, Y. (1981). Sheet metal CAD/CAM system. Bulletin—Japan Society of Precision Engineering, 15, 219–224.

Tor, S. B., Britton, G. A., & Zhang, W. Y. (2005). Development of an object-oriented blackboard model for stamping process planning in progressive die design. Journal of Intelligent Manufacturing, 16(4–5), 499–513.

Vosniakos, G.-C., & Gianakakis, T. (2012). A knowledge-based manufacturing advisor for pressworked sheet metal parts. Journal of Intelligent Manufacturing. doi:10.1007/s10845-012-0664-3.

Vosniakos, G. C., Segredou, I., & Gianakakis, T. (2005). Logic programming for process planning in the domain of sheet metal forming with progressive dies. Journal of Intelligent Manufacturing, 16, 479–497.

Zadeh, L. A. (1965). Fuzzy sets. Information and Control, 8, 339–353.

Author information

Authors and Affiliations

Corresponding author

Additional information

The authors experience and observations in “progressive dies for Iran khodro automotive Company and other Iranian companies” Tehran, Iran.

Rights and permissions

About this article

Cite this article

Moghaddam, M.J., Soleymani, M.R. & Farsi, M.A. Sequence planning for stamping operations in progressive dies. J Intell Manuf 26, 347–357 (2015). https://doi.org/10.1007/s10845-013-0788-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-013-0788-0