Abstract

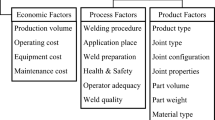

This paper describes a research work to develop a computer-aided design of a product with bending and piercing operations for progressive working. The approach to the system is based on knowledge-based rules. Knowledge for the system is formulated from plasticity theories, experimental results and the empirical knowledge of experts in the field. The system has been written in AutoLISP with AutoCAD on a personal computer and is composed of three main modules: input and shape treatment, flat pattern layout, and strip layout modules. The system is designed by considering several factors, such as piercing and bending sequence by fuzzy set theory, complexities of blank geometry, punch profiles, and the availability of press equipment. The strip layout module generates the 3D strip layout drawing with the punch profiles for the external area of a product according to the results of the FVM set. The system could serve as a valuable system for experts and as a dependable training aid for beginners.

Similar content being viewed by others

References

Fogg B, Jaimeson G (1975) The influencing factors in optimizing press tool die layouts and a solution using computer aids. Ann CIRP 24:429–434

Shibata Y, Kunitomo Y (1981) Sheet metal CAD/CAM system. Bull Jpn Soc Prec Eng 15:219–224

Nakahara S, Kojima T, Tamura S, Funimo A, Choichiro S, Mukumuru T (1978) Computer progressive die design. Proceedings of the 19th MTDR conference, pp 171–176

Wang F, Chang L (1995) Determination of the bending sequence in progressive die design. Proc Instn Mech Engrs 209:67–73

See Toh KH, Loh HT, Nee AYC, Lee KS (1995) A feature-based flat pattern development system for sheet metal parts. J Mater Process Technol 48:89–95

Choi JC, Kim C, Choi Y, Kim JH, Park JH (2000) An integrated design and CAPP system deep drawing and blanking products. Int J Adv Manuf Technol 16:803–813

Choi JC, Kim C, Yoon JH (2000) An automated CAD system for progressive working of irregular shaped metal products and lead frame for semiconductor. Int J Adv Manuf Technol 16:624–634

Ong SK, De Vin LJ, Nee AYC, Kals HJJ (1997) Fuzzy set theory applied to bend sequencing for sheet metal bending. J Mater Process Technol 69:29–36

Aomura S, Koguchi A (2002) Optimized bending sequences of sheet metal bending by robot. J Robotic Comp Integr Manuf 18:29–39

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, J.H., Kim, C. & Chang, Y.J. Development of a process sequence determination technique by fuzzy set theory for an electric product with piercing and bending operation. Int J Adv Manuf Technol 31, 450–464 (2006). https://doi.org/10.1007/s00170-005-0227-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0227-2