Abstract

Food production will have to increase significantly to meet the nutritional needs of the global population. There is also an urgent need to increase the sustainability of food production. Microalgae are a potential sustainable alternative to conventional protein sources and they can also be used in other industries such as agriculture or aquaculture. In this work, the cyanobacterium Arthrospira platensis was produced in Almeria (Spain) in a pilot-scale reactor (80 m2). The biomass produced was used as a protein source and a plant biostimulant following a biorefinery approach. Biomass productivity reached 5.6 g m−2 day−1. The biomass was rich in proteins (67.8 g (100 g)−1) and pigments, namely chlorophyll (7.6 mg (100 g)−1) and phycocyanin (134.2 mg (100 g)−1). An isoelectric solubilisation/precipitation method assisted by ultrasound led to the recovery of a protein extract with a protein content of 91.3 g (100 g)−1. The protein isolate was evaluated as a source of essential amino acids in tagliatelle, leading to an increase in the content of histidine, leucine, lysine, methionine, phenylalanine, threonine, and valine of 36.3, 75.2, 26.3, 30.0, 45.7, 57.8, and 70.0%, respectively. The protein content also increased from 9.6 to 13.9 g (100 g)−1 when the protein isolate was incorporated at a flour substitution level of 4%. The leftovers from the protein extraction were evaluated as plant biostimulants, for which auxin- and cytokinin-like effects were observed. Root development was especially promoted. The results demonstrated the feasibility of producing Spirulina during the winter in Europe and the potential simultaneous use of the biomass as a food ingredient and as a plant biostimulant.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microalgae are generally rich in proteins and bioactive pigments (e.g. carotenoids or phycobiliproteins) and can be used as healthy food ingredients (Lafarga 2019). Microalgae can also be utilised as biofertilisers or biostimulants in agriculture (Refaay et al. 2021) or as a functional aquafeed ingredient (Shah et al. 2018). Because of their many potential applications, microalgae are one of the most promising sources of new foods and agricultural products (Chen et al. 2022; Morillas-España et al. 2022a). Chlorella vulgaris and Arthrospira platensis, the latter commercialised as Spirulina, can be sold in the EU as food. However, the number of products containing microalgae that are available on the market is relatively low. To increase the production and consumption of microalgae, more tasty and nutritious foods containing microalgae must be developed and commercialised.

A recent work revealed that pasta is one of the preferred food matrices to use as a delivery vehicle for microalgae-derived bioactive ingredients (Lafarga et al. 2021a). Pasta has the added advantages of being a low-cost product that is easy to prepare and one consumed in most parts of the world. However, as pasta is a wheat-based product, it has a low protein content (~ 11%) and is deficient in essential amino acids including lysine, methionine and threonine. The supplementation of wheat pasta with fish powder and other protein-rich ingredients has been evaluated as a strategy to improve the pasta’s nutritional value (Desai et al. 2018). Arthrospira is known for its high protein content, which can range between 50–70% depending on the strain and on the growing and environmental conditions (Lafarga et al. 2020); it can also be used to enrich pasta products. Indeed, previous works have evaluated the effect of Arthrospira on the cooking quality, bioactive properties, and dough attributes of pasta (Özyurt et al. 2015; Fradinho et al. 2020; Genc Polat et al. 2020; Zen et al. 2020). Because of its high pigment content, products containing the whole biomass of Arthrospira are green. The green colour of microalgae is generally a challenge when used in foods that are not normally this colour. Nonetheless, green pasta products, which are usually coloured using spinach or other vegetables, are common in the EU market. Encapsulation (Genc Polat et al. 2020) or incorporating the biomass into naturally green (Lafarga et al. 2019) or very dark (Rouphael and Colla 2018) food matrices have also been assessed as strategies to mask the green colour of microalgae.

To introduce more protein and essential amino acids into the pasta, the present work aimed to develop fresh tagliatelle enriched with a Arthrospira-derived protein isolate generated by an isoelectric solubilisation/precipitation strategy. In this work, the remaining fraction was evaluated for use as an agricultural biostimulant. Future works will evaluate the potential use of these protein extraction leftovers as aquafeed ingredients and as techno-functional food ingredients (e.g., thickeners). Plant biostimulants promote the germination of seeds and the growth and flowering of plants as well as increase plant nutrient-use efficiencies and the plants’ resistance to abiotic stress (Rouphael and Colla 2018). Therefore, these products have become increasingly important. By following a biorefinery scheme, where more than one valuable compound is recovered from the microalgal biomass, it is possible to increase its economic viability and avoid the generation of waste and/or low-value co-products. The developed process has the added advantage of using water alone as the solvent to produce the protein isolate and the plant biostimulant. The microalga used in this work was Arthrospira platensis (Spirulina), which was produced in 80 m2 raceway reactors located inside a greenhouse. The location of the photobioreactor inside a greenhouse reduces the risk of contaminations. This risk is relatively low in Arthrospira cultures as Arthrospira is an alkaliphile strain and its extreme growth conditions avoid or limit the appearance of unwanted microorganisms (Lafarga et al. 2021c).

Materials and methods

Microalgae production

Arthrospira platensis was purchased from the Spanish Bank of Algae (Las Palmas de Gran Canaria, Spain; Code: BEA 005B). It was produced in 80 m2 (9 m3) raceway reactors as described elsewhere (Villaró et al. 2022a). The medium used for biomass production was prepared using commercial fertilisers (NaNO3, KH2PO4, MgSO4·7H2O, CaCl2·2H2O, NaHCO3 and Karentol®, a commercial mixture of micronutrients). Fertilisers were selected as the preferred nutrient source because they are available in large quantities, are unexpensive, and are the main nutrient source for microalgae production at the commercial scale. The reactors were operated in semi-continuous mode at a dilution rate of 0.10 day−1. The depth of the reactors was 0.10 m and evaporation was compensated for daily with freshwater. The biomass harvesting was carried out using an SSD 6–06-007 centrifuge (GEA Westfalia Separator, Germany). Subsequently, the algal paste was vacuum sealed and stored at 4 ºC until further use. The biomass concentration and the Fv/Fm value of the culture were determined daily as described elsewhere (Villaró et al. 2022a). The biomass used to produce the pasta was collected over the last 3 days of semi-continuous production.

Protein extraction

Proteins were extracted following a previously described ultrasound-assisted methodology with slight modifications (Sánchez-Zurano et al. 2020). The biomass was suspended in water up to a final concentration of 10 g L−1. This concentration was selected because it can be easily achieved using ultrafiltration membranes. The biomass was disrupted with a UP400S ultrasonic processor (Hielscher Ultrasound Technology, Germany). The disruption efficiency was estimated by measuring the conductivity and optical density changes during sonication (Grimi et al. 2014). The conductivity was measured using an HQ1140 conductivity meter (Hach Lange Spain, Spain) while the optical density was measured using a Genesys 10S UV–Vis spectrophotometer (Thermo Fisher Scientific, Spain). The proteins were isolated by isoelectric precipitation at pH 3.9, which is the pH value that enables the greatest amount of proteins to be recovered from A. platensis (Sánchez-Zurano et al. 2020). The protein-rich fraction, labelled as F-I, was freeze-dried, vacuum sealed, and stored in the dark at -20 ºC until further use. The supernatant from the protein precipitation was amalgamated with the pellet obtained after the first centrifugation, freeze-dried, and stored in the dark at -20 ºC until further use. This fraction was labelled as F-II.

Production of microalgae-enriched tagliatelle

The control tagliatelle (CT) was prepared using: 400 g of wheat flour and 160 mL of water. The pasta was made using a Philips HR2345/19 pasta maker (Philips, Spain). Each individual piece of tagliatelle was 30 cm long, 7 mm width and 1 mm in height. Two groups of microalgae-containing tagliatelle were prepared. The first contained the whole biomass of A. platensis and was prepared by replacing the wheat flour with the biomass at flour substitution percentages of 1, 2, 3 or 4% (w/w). These samples were labelled as BT1%, BT2%, BT3% and BT4%, respectively with BT standing for “biomass tagliatelle”. The second group of tagliatelle was prepared by replacing the wheat flour with F-I (the protein isolate) at flour substitution percentages of 1, 2, 3 or 4% (w/w). These samples were labelled as PT1%, PT2%, PT3% and PT4%, respectively, with PT standing for “protein tagliatelle”. Three different batches (400 g of dry matter) were prepared for each type of pasta, each batch being a natural replicate. The pasta was boiled for 2 min and immediately immersed in ice-cold water for 3 min to avoid overcooking. The tagliatelle were then dried using a paper towel and either analysed directly (e.g., for colour) or frozen until further use (e.g. to assess its protein content).

Quality assessment

The cooking loss, water absorption index, and swelling index were calculated as described in a previous work (Albors et al. 2016). The water absorption index was calculated using the equation:

The cooking loss refers to the amount of solid lost to the cooking water whereas the swelling index refers to the relative volume change between the uncooked and cooked pasta. The tagliatelle dimensions were measured using a calliper.

Colour measurements were taken using a Minolta CR-400 chroma meter (Minolta Inc., Japan). The L*, a*, and b* values were recorded in triplicate. The L* value represents lightness from black to white on a scale from 0 to 100, while the a* and b* values represent the red/green and yellow/blue coordinates, respectively.

Macromolecular composition

The dry matter and ash content of the pasta products were analysed following AOAC methods while the total protein content was estimated by elemental analysis (C:H:N) using a Fisons EA 1108 analyser (Fisons Instruments, USA) and a nitrogen-to-protein conversion factor of 5.25. The total lipid content of the pasta products was calculated following the Folch method using a mixture of chloroform and methanol. The total carbohydrate content of the pasta products was calculated by difference. The energy content of the tagliatelle was estimated using the conversion factor recommended by the FAO: 17 kJ g−1 (4.0 kcal g−1) for protein, 37 kJ g−1 (9.0 kcal g−1) for lipids and 17 kJ g−1 (4.0 kcal g−1) for carbohydrates. The pigment content of the biomass was estimated as described elsewhere (Rodrigues et al. 2019; Ciardi et al. 2022).

Amino acid content

The analysis of amino acids was conducted as described in a previous work (Taragjini et al. 2022). First, 100 mg of freeze-dried F-I (protein-rich extract) were hydrolysed using 10 mL of 6 M HCl at 110 ºC. After 24 h the hydrolysate was filtered using HPLC filters (0.45 µm, 3 mm), washed three times with 1 mL of 0.1 M HCl, and evaporated to dryness under nitrogen at 40 ºC. Then, the residue was suspended in 2 mL of distilled water and analysed by HPLC using a Perkin Elmer Series 200 HPLC coupled to a Perkin Elmer Altus A-10 fluorescence detector. Mobile phase A consisted of methanol:acetonitrile (12:1, v:v) while mobile phase B comprised 23 mM sodium acetate at a pH of 5.95. The gradient elution used for the separation of the amino acids was a 75 min linear gradient of mobile phase B from 0 to 53% and 20 min of 100% mobile phase A. The flow rate was 1 mL min−1. Each individual amino acid identified by comparing its retention time to that of the commercial standard (Sigma-Aldrich, USA).

Antioxidant pigments and antioxidant capacity

The total content of carotenoids and chlorophylls was estimated as described in a previous work (Villaró et al. 2022b) using a Genesys 10S UV–Vis spectrophotometer (Thermo Fisher Scientific, Spain). Phycobiliproteins were also estimated spectrophotometrically following a previously described methodology (Rodrigues et al. 2019). In addition, the antioxidant capacity of the tagliatelle was assessed using the ferric reducing antioxidant power (FRAP) and the 2,2-diphenyl-1-picrylhydrazyl (DPPH) scavenging activity assays following previously described methods (Nicolau-Lapeña et al. 2019) with a minor modification. In the present study, the extract was obtained using 100 mg of freeze-dried tagliatelle and 5 mL of a mixture of methanol:water (70:30, v/v). The extraction of the antioxidant compounds was carried out by stirring at 350 rpm for 30 min at 21 ± 1 ºC. The preparation of the reagents and the determination of the antioxidant capacity were carried out as described in the above-mentioned work.

Assessment of the biostimulant activity

The biostimulant capacity of F-II and of the whole biomass was assessed using previously reported methodologies (Morillas-España et al. 2022b). The germination index was assessed using watercress seeds (Lepidium sativum L.). Briefly, 25 watercress seeds were placed on a Whatman No. 5 filter paper inside a sterile Petri dish. The Petri dishes were treated with either 2 mL of distilled water, 2 mL of F-II suspended in distilled water, or the whole biomass suspended in distilled water. The whole biomass and F-II were assessed at concentrations of 0.1 and 0.5 g L−1. Each treatment was performed using three Petri dishes containing 25 seeds each. The seeds were allowed to grow for 3 days at 24 ºC in the dark. The germination index was determined using the equation shown below, where \(N\) and \({N}_{c}\) refer to the number of germinated seeds after treatment with algal extracts or distilled water, respectively and \(L\) and \({L}_{c}\) refer to the average length of the germinated seeds treated with algal extracts or distilled water, respectively.

In addition, the root development was calculated using soybeans (Glycine max L.) and the plant growth was calculated using the cucumber (Cucumis sativus L.) expansion test. To assess the root development, soybeans were planted at a depth of 1 cm in moistened perlite and kept in a growth chamber at 27 ºC with controlled 12/12 h light/dark cycles. After one week of incubation, three seedlings were cut 3 cm below the cotyledon and placed in vials containing 20 mL of distilled water or microalgal extract. The seedlings were then incubated at 27 ºC with 12/12 h light/dark cycles for one week. The algal extracts were assessed at a concentration of 0.5 or 2.0 g L−1. Then, the adventitious roots on each hypocotyl that were longer than 1 mm were counted. To assess the cytokinin-like effect, cucumber seeds were placed on glass trays with 0.7% agar-solidified Knop nutrient medium containing 450 mL of distilled water, 3.5 g of bacteriological agar, and 50 mL of KNOP solution. The seeds were then incubated in the dark for 5 days at 27 ºC. Subsequently, 5 uniform cotyledons were weighed and transferred to 60 mm Petri dishes containing a Whatman No. 5 filter paper wetted with either 3 mL of distilled water or microalgal extract at a concentration of 0.5 or 2.0 g·L−1.

Finally, the chlorophyll retention assay was performed using wheat (Triticum aestivum L.). Briefly, wheat seeds were planted at a 1 cm depth in moistened perlite and incubated in a controlled chamber for 10 days at 25 ºC and 65% relative humidity with 12/12 h light/dark cycles. The leaves of the seedlings were then excised in 10 mm segments, cut 3 cm from their apical tip. The fresh weight of 40 segments was measured per treatment. The segments were placed in 50 mL vials containing 10 mL of either distilled water or microalgal extract at a concentration of 0.5 or 2.0 g L−1. The vials were subsequently returned to the controlled chamber for 4 more days. The leaves were then blot dried and extracted with 8 mL of 80% methanol at 80 ºC for 10 min. The extract was centrifuged and the optical density of the supernatant was determined at 645 nm. The negative control was distilled water whereas the plant hormones 6-benzylaminopurine (BAP), indol-3-butyric acid (IBA) and gibberellic acid (GA3) were used as positive controls.

Statistical analysis

The results were analysed by ANOVA using Statgraphics v.18 software (Statgraphics Technologies Inc., USA). Duncan’s multiple range test was used to identify differences between samples (p < 0.05).

Results

Biomass production and processing

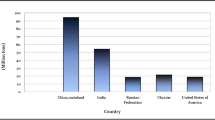

The biomass concentration achieved during the batch and semi-continuous production of A. platensis is shown in Fig. 1A. Overall, the maximum concentration reached was around 0.4 g·L−1 after approximately 10 days of production. In the present work, the average temperature and solar radiation that reached the culture inside the greenhouse were around 13 ºC and 600 μmol photons m−2 s−1. These conditions allowed a biomass productivity of 5.6 ± 0.9 g m−2 day−1 to be achieved. The macromolecular composition of the produced biomass was 67.8 ± 1.5, 13.6 ± 2.7, 9.6 ± 0.6, and 8.9 ± 0.6% of proteins, carbohydrates, lipids, and ashes, respectively. Moreover, in terms of pigments, the total carotenoids and chlorophyll content were estimated as 1.9 ± 0.1 and 7.6 ± 0.2 mg (100 g)−1, respectively. The phycocyanin and allophycocyanin contents of the biomass were 134.2 ± 1.1 and 39.5 ± 1.7 mg (100 g)−1, respectively. Figure 1A also shows the daily Fv/Fm value during the biomass production. Overall, no differences were observed between the different days, with the value being around 0.5 in all cases.

(A) Biomass concentration and Fv/Fm values during the biomass production. The biomass production was carried out using three identical photobioreactors (dilution rate = 0.1 day−1, culture depth = 0.10 m). (B) Ratio of the electrical conductivity or optical density (750 nm) after and before sonication against the specific sonication power consumption. The results are the average of three independent determinations ± SD

Figure 1B shows the amount of energy needed to disrupt the microalgal cells. The results revealed that applying 10 MJ·kg−1 led to the highest increase in conductivity; this can be correlated with the release of intracellular content. Lower energy inputs also led to increased conductivities and optical densities (750 nm); for example, an energy input of 5 MJ kg−1 led to a conductivity increase that was approximately 80% of the maximum value achieved. After the cell wall was disrupted applying 10 MJ kg−1, the biomass was used as a feedstock to produce a protein isolate rich in essential amino acids following an isoelectric solubilisation-precipitation strategy. The protein content of the isolate, which was labelled as F-I, was 91.1% on a dry weight basis.

Utilising F-I as a source of essential amino acids

Both, F-I and the whole biomass were used as ingredients to produce tagliatelle at flour substitution levels of 1–4% (Fig. 2). The colour attributes of the different pasta samples are shown in Table 1. The incorporation of F-I and especially the whole biomass led to a significant decrease in the L* value of the fresh pasta, denoting a lower lightness (p < 0.05). In turn, a* and b* express the four colours of human vision green/red and yellow/blue, respectively. Even though both the whole biomass and the F-I decreased the a* value, the lowest (which expresses a greener hue) was observed when the whole biomass was used as an ingredient. In addition, the colour attributes of the cooked pasta were determined by boiling for 2 min; this led to a decrease in the L* values and an increase in the a* and b* values, respectively.

One of the goals of this work was to assess the effect on the protein and amino acid content of wheat tagliatelle by incorporating Arthrospira. The macromolecular composition of the pasta is shown in Table 2. Overall, the incorporation of the whole biomass or F-I led to a higher protein content at all the concentrations studied (p < 0.05). The protein content of the pasta was highest when the tagliatelle was enriched with F-I. Another major effect on the pastas’ macromolecular composition was a lower carbohydrate content, especially at the higher flour substitution levels studied (p < 0.05). In addition, the energy content of the pasta was not affected, the level being approximately 400 kcal (100 g)−1. The pastas’ amino acid content is shown in Table 3. Incorporating F-I at a flour substitution level of 4% led to an increase in the content of histidine, leucine, lysine, methionine, phenylalanine, threonine, and valine of 36.3, 75.2, 26.3, 30.0, 45.7, 57.8, and 70.0%, respectively. Incorporating the whole biomass also led to a higher essential amino acid content; in this case, the contents of histidine, leucine, lysine, methionine, phenylalanine, threonine, and valine were 27.2, 45.9, 23.7, 21.7, 42.9, 52.6, and 42.5% higher, respectively. The total amino acid content increased in all the studied samples, even when the whole Arthrospira biomass was introduced at a flour substitution level of 1% (Table 3).

Utilising F-II as a plant biostimulant

Fraction F-II, the leftovers obtained after the protein recovery, were assessed as a plant biostimulant. The results are summarised in Fig. 3. In the present work, the germination index was negatively affected by the addition of both, the whole biomass and F-II. Conversely, F-II led to a significant increase in root formation (p < 0.05). When assessed at a concentration of 2 g L−1, the observed increase was almost 300%, higher than that of the positive control (the control was assessed at a much lower concentration). In addition, the cotyledon expansion test revealed the biostimulant effect of F-II, with the cotyledon weight being approximately 15% higher compared to using water alone (p < 0.05). In this case, the whole biomass presented greater activity, of around 25–35%, depending on the concentration studied. The cytokinin-like effects of the biomass and of the microalgae-derived extract were also determined using the chlorophyll retention test. A positive effect was observed both when applying the whole biomass and when applying F-II.

(A) Germination index. (B) adventitious root formation. (C) cotyledon weight gain, and (D) chlorophyll content of the wheat leaves. All the values represent the percentage of variation with respect to distilled water. Values represent mean values ± SD. Different letters indicate significant differences (p < 0.05)

Discussion

Arthrospira (Spirulina) is the most widely consumed microalga in the EU. It is generally utilised as a protein supplement and is well accepted by European consumers who believe it to be safe, nutritious, and sustainable (Lafarga et al. 2021a). Most of the Arthrospira biomass consumed today is produced in Asia although the number of companies that are starting to produce Arthrospira in the EU is growing each year. In Almeria, in winter, the biomass productivity was 5.6 ± 0.9 g m−2 day−1. This value is relatively low compared to that obtained for other microalgae such as Scenedesmus (15 g m−2 day−1) (Morillas-España et al. 2021b) or Anabaena (20.1 g m−2 day−1) (Morillas-España et al. 2021a). The main reason for these differences is the use of different microalgal strains and the different environmental conditions during biomass production. In the present work, production was carried out in winter and the metabolic activity of Spirulina decreases significantly at temperatures below 17 ºC. Indeed, when using these same reactors in summer, the biomass productivity was around 30 g·m−2·day−1 after optimising the operational conditions (Villaró et al. 2022a). The results are in line with a recent work in which Arthrospira sp. LEB-18 was cultivated in different regions of Brazil. These authors demonstrated that the biomass productivity in the south of the country (where the temperatures are lower) was inferior to that in the north, where the climatic conditions were more suitable for producing Arthrospira (de Jesus et al. 2018). The Fv/Fm value of the culture was around 0.5. This value is within the normal range for prokaryotic cyanobacteria. It is slightly lower than that of most eukaryotic microalgae (which is generally around 0.6) because of interferences between phycobiliproteins and the fluorescence signal (Schagerl et al. 2022). This suggests that, despite the low temperatures, the cells were not stressed by factors ranging from an excess of light to the presence of toxins or a lack of nutrients. The biomass produced was especially rich in proteins and carbohydrates. Its composition was comparable to that of commercial Arthrospira powders available from the USDA Food Data Central database available at https://fdc.nal.usda.gov/index.html.

One of the main challenges in recovering valuable compounds from microalgal biomass is their tough cell wall. In the case of Arthrospira, its cell wall is divided into four layers, two of them formed by fibrillary molecules, a peptidoglycan layer, and another covered with acidic polysaccharides (Chen et al. 2020). Various strategies have been assessed to disrupt the cell wall of Arthrospira, such as ultrasound, high pressure homogenisation, bead milling, ohmic heating, or pulsed electric fields (Lafarga et al. 2021b). In the present study, ultrasound was used. The goal was to identify the amount of energy needed to disrupt the cell wall. The results, suggested that maximal disruption was achieved by applying 10 MJ kg−1; hence, this was the energy applied in the present study. Future works will assess the protein recovery yields following milder disruption strategies. The isolated proteins were used as a protein source in wheat tagliatelle (Fig. 2). As can be observed, all the samples were green in colour, although the samples produced using F-I were a much lighter green. This would be expected as the content of chlorophyll (the pigment responsible for the green colour of microalgae) was lower in the pasta products enriched with F-I (Fig. 4). The higher a* and b* values after boiling denote a loss of green and blue hues, probably caused by the degradation or denaturalisation of the chlorophyll (green) and phycobiliproteins (blue). This is because chlorophyll are very sensitive to temperature. Indeed, the conversion of chlorophyll to pheophytin and pheophorbide, caused by the influence of pH or temperature, is one of the main reasons for the green decolouration of vegetables during processing (Andrés-Bello et al. 2013). This reaction turns the green colour of vegetables or algae from a bright green to a dull olive green or brown. In this case, because of the short cooking time, the colour of the pasta remained dark green. Phycobiliproteins are likewise degraded by high temperatures. Their stability during food processing has recently been reviewed (Nowruzi et al. 2022). Evidently, the boiling of pasta products cannot be avoided; nonetheless, there are some strategies that can be followed to increase the in vivo bioactivity of microalgae-derived compounds. For example, previous works have suggested that a cell wall disruption stage can promote the release of bioactive compounds and increase their bioaccessibility (Demarco et al. 2022). The use of mild disruption technologies and the encapsulation of the bioactive compounds have also been suggested as potential strategies to promote bioavailability (Cai et al. 2021).

The protein content of the biomass enriched with the protein isolate was higher than when the whole biomass was used; this would be expected given that the F-I protein content was 91% whereas the whole biomass had a protein concentration of 68%. Essential amino acids, including histidine, leucine, lysine, methionine, phenylalanine, threonine, tryptophan, and valine cannot be synthesised by the human body. They are present in animal proteins, whereas most vegetables lack one or more essential amino acids. For example, lysine is a limiting essential amino acid in rice (Zhao et al. 2020). Arthrospira, on the other hand, contains all the essential amino acids and, for this reason, it has been commercialised as a protein supplement for vegans. The essential amino acid content was higher in both the F-I and the whole biomass enriched pasta. A previous study also demonstrated an increased content of amino acids and essential amino acids after incorporating Arthrospira in pork sausages (Marti-Quijal et al. 2019). In that study, the goal was to reduce the amount of animal proteins used during the sausage production, as the consumption of processed meat has been associated with different types of cancer. Likewise, the essential amino acid content of bread was higher adding of Arthrospira at concentrations of 1 or 2% (Montevecchi et al. 2022). Other wheat-based products have been effectively enriched with essential amino acids using the microalgae Michrocloropsis gaditana, Chlorella vulgaris and Tetraselmis chuii (Qazi et al. 2021).

Finally, the leftovers following protein recovery, labelled as F-II, were assessed as plant biostimulants. Plant biostimulants are an agricultural option attracting ever greater interest because of their potential to increase crop yields and simultaneously reduce water and fertiliser requirements (Morillas-España et al. 2022a). Several microalgal strains demonstrated biostimulant effects in the past. For example, C. vulgaris assessed at a concentration of 0.1 g L−1 increased the germination index of watercress seeds by approximately 2% and promoted root development by over 200% compared to water alone (Amaya-Santos et al. 2022). Similarly, the microalga Scenedesmus quadricauda positively affected the development of lettuce seedlings especially at the shoot level and increasing their dry matter and pigment content (Puglisi et al. 2020). However, to the best of the authors’ knowledge, this is the first time that the leftovers of protein extraction were assessed as a plant biostimulant. Germination was negatively affected by both the whole biomass and F-II. This means that the extract probably does not promote seed germination, which is initiated by gibberellins in plants (Plaza et al. 2018). This effect is strain-dependent and previous works have also observed a negative effect on germination (Navarro-López et al. 2020). Auxins are the main hormones involved in promoting root initiation and elongation as well as in increasing the number of roots and lateral roots (Keswani et al. 2020). The results suggested that F-II had an auxin-like effect, which was even higher than that of the whole biomass (studied at the same concentration). Recent works have likewise observed improved rooting capacity in maize after applying Chlorella sorokiniana and Chlamydomonas reinhardtii (Martini et al. 2021). In that study, both microalgae promoted the development of roots but the former mainly increased the number of secondary roots and the latter improved the accumulation of micronutrients on roots and shoots. In this work, both F-II and the whole biomass of A. platensis BEA 005B presented a cytokinin-like effect; these are hormones that are derived from adenine and they participate in the regulation of growth, plant physiological activities, and the plant’s response to abiotic stress (Li et al. 2021). In previous works, other microalgal strains also presented a cytokinin-like effect (Refaay et al. 2021; Morillas-España et al. 2022b; Puglisi et al. 2022). Given that the biostimulant effect is dose-dependent, future works will need to validate the strains’ bioactivity in vivo and estimate their optimal dosage.

Conclusions

Arthrospira platensis BEA 005B (Spirulina) can be produced in the south of Spain despite the suboptimal environmental conditions. The produced biomass was of a high quality and rich in essential amino acids. The incorporation of both, the whole biomass and a Arthrospira-derived protein isolate, led to an increase in the contents of proteins and essential amino acids in wheat tagliatelle. The addition of Arthrospira also enriched the chlorophyll and phycocyanin contents in the tagliatelle. The leftovers from protein extraction were assessed for their biostimulant effects. They demonstrated a very potent auxin-like effect, which was even higher than that for the whole biomass.

Data availability

The data related with microalgal biomass production are available at http://sabana.ual.es. The remaining data are available on reasonable request from the corresponding author.

Change history

21 August 2023

Incorrect Open Access funding information has been corrected in the Funding Note.

References

Albors A, Raigon MD, García-Martinez MD, Martín-Esparza ME (2016) Assessment of techno-functional and sensory attributes of tiger nut fresh egg tagliatelle. LWT 74:183–190

Amaya-Santos G, Ruiz-Nieto Á, Sánchez-Zurano A, Ciardi M, Gomez-Serrano C, Acien G, Lafarga T (2022) Production of Chlorella vulgaris using urban wastewater: Assessment of the nutrient recovery capacity of the biomass and its plant biostimulant effects. J Appl Phycol 34:2971–2979

Andrés-Bello A, Barreto-Palacios V, García-Segovia P, Mir_bel J, Martinez-Monzo J (2013) Effect of pH on color and texture of food products. Food Eng Rev 5:158–170

Cai Y, Lim HR, Khoo KS, Ng HS, Cai Y, Wang J, Tak-Yee Chan A, Show PL (2021) An integration study of microalgae bioactive retention: From microalgae biomass to microalgae bioactives nanoparticle. Food Chem Toxicol 158:112607

Chen C, Tang T, Shi Q, Zhou Z, Fan J (2022) The potential and challenge of microalgae as promising future food sources. Trends Food Sci Technol 126:99–112

Chen W, Xu J, Yu Q, Yuan Z, Kong X, Sun Y, Wang Z, Zhuang X, Zhang Y, Guo Y (2020) Structural insights reveal the effective Spirulina platensis cell wall dissociation methods for multi-output recovery. Bioresour Technol 300:122628

Ciardi M, Gómez-Serrano C, del Mar Morales-Amaral M, Acien G, Lafarga T, Fernadez-Sevilla JM (2022) Optimisation of Scenedesmus almeriensis production using pig slurry as the sole nutrient source. Algal Res 61:102580

de Jesus CS, da Silva Uebel L, Costa SS, Miranda AL, de Morais EG, de Morais MG, Costa JAV, Nunes IL, de Souza Ferreira E, Druzian JI (2018) Outdoor pilot-scale cultivation of Spirulina sp. LEB-18 in different geographic locations for evaluating its growth and chemical composition. Bioresour Technol 256:86–94

Demarco M, Oliveira de Moraes J, Matos ÂP, Derner RB, Neves FdF, Tribuzi G (2022) Digestibility, bioaccessibility and bioactivity of compounds from algae. Trends Food Sci Technol 121:114–128

Desai AS, Brennan MA, Brennan CS (2018) Amino acid and fatty acid profile and digestible indispensable amino acid score of pasta fortified with salmon (Oncorhynchus tshawytscha) powder. Eur Food Res Technol 244:1729–1739

Fradinho P, Niccolai A, Soares R et al (2020) Effect of Arthrospira platensis (spirulina) incorporation on the rheological and bioactive properties of gluten-free fresh pasta. Algal Res 45:101743

Genc Polat D, Durmaz Y, Konar N, Toker OS, Palabiyik I, Tasan M (2020) Using encapsulated Nannochloropsis oculata in white chocolate as coloring agent. J Appl Phycol 32:3077–3088

Grimi N, Dubois A, Marchal L, Jubeau S, Lebovka NI, Vorobiev E (2014) Selective extraction from microalgae Nannochloropsis sp. using different methods of cell disruption. Bioresour Technol 153:254–259

Keswani C, Singh SP, Cueto L, García-Estrada C, Mezaache-Aichour S, Glare TR, Borriss R, Singh SP, Blázquez MA, Sansinenea E (2020) Auxins of microbial origin and their use in agriculture. Appl Microbiol Biotechnol 104:8549–8565

Lafarga T (2019) Effect of microalgal biomass incorporation into foods: Nutritional and sensorial attributes of the end products. Algal Res 41:101566

Lafarga T, Acién-Fernández FG, Castellari M, Villaro S, Bobo G, Aguilo-Aguayo I (2019) Effect of microalgae incorporation on the physicochemical, nutritional, and sensorial properties of an innovative broccoli soup. LWT 111:167–174

Lafarga T, Fernández-Sevilla JM, González-López C, Acién-Fernández FG (2020) Spirulina for the food and functional food industries. Food Res Int 137:109356

Lafarga T, Rodríguez-Bermúdez R, Morillas-España A, Villaró S, García-Vaquero M, Morán L, Sánchez-Zurano A, González-López CV, Acién-Fernández FG (2021a) Consumer knowledge and attitudes towards microalgae as food: The case of Spain. Algal Res 54:102174

Lafarga T, Sánchez-Zurano A, Villaró S et al (2021b) Industrial production of spirulina as a protein source for bioactive peptide generation. Trends Food Sci Technol 116:176–185

Lafarga T, Sánchez‐Zurano A, Morillas‐España A, Acién‐Fernández FG (2021c) Extremophile microalgae as feedstock for high‐value carotenoids: A review. Int J Food Sci Technol 56:934–4941

Li SM, Zheng HX, Zhang XS, Sui N (2021) Cytokinins as central regulators during plant growth and stress response. Plant Cell Rep 40:271–282

Marti-Quijal FJ, Zamuz S, Tomašević I, Gomez B, Rocchetti G, Lucini L, Remize F, Barba FJ, Lorenzo JM (2019) Influence of different sources of vegetable, whey and microalgae proteins on the physicochemical properties and amino acid profile of fresh pork sausages. LWT 110:316–323

Martini F, Beghini G, Zanin L, Varanini Z, Zamboni A, Ballottari M (2021) The potential use of Chlamydomonas reinhardtii and Chlorella sorokiniana as biostimulants on maize plants. Algal Res 60:102515

Montevecchi G, Santunione G, Licciardello F, Köker Ö, Masino F, Antonelli A (2022) Enrichment of wheat flour with Spirulina. Evaluation of thermal damage to essential amino acids during bread preparation. Food Res Int 157:111357

Morillas-España A, Lafarga T, Sánchez-Zurano A, Acién-Fernández FG, González-López C (2022a) Microalgae based wastewater treatment coupled to the production of high value agricultural products: Current needs and challenges. Chemosphere 291:132968

Morillas-España A, Ruiz-Nieto Á, Lafarga T, Acién G, Arbib Z, González-López CV (2022b) Biostimulant capacity of Chlorella and Chlamydopodium species produced using wastewater and centrate. Biology 11:1086

Morillas-España A, Sánchez-Zurano A, Gómez-Serrano C, Ciardi M, Acien G, Clagnan E, Adani F, Lafarga T (2021a) Potential of the cyanobacteria Anabaena sp. and Dolichospermum sp. for being produced using wastewater or pig slurry: Validation using pilot-scale raceway reactors. Algal Res 60:102517

Morillas-España A, Sánchez-Zurano A, Lafarga T, del Mar Morales-Amaral M, Gómez-Serrano C, Acién-Fernández FG, González-López CV (2021b) Improvement of wastewater treatment capacity using the microalga Scenedesmus sp. and membrane bioreactors. Algal Res 60:102516

Navarro-Lopez E, Ruiz-Nieto A, Ferreira A, Acien FG, Gouveia L (2020) Biostimulant Potential of Scenedesmus obliquus grown in brewery wastewater. Molecules 25:664

Nicolau-Lapeña I, Abadias M, Bobo G, Aguiló-Aguayo I, Lafarga T, Viñas (2019) Strawberry sanitization by peracetic acid washing and its effect on fruit quality. Food Microbiol 83:159–166

Nowruzi B, Konur O, Anvar SAA (2022) The stability of the phycobiliproteins in the adverse environmental conditions relevant to the food storage. Food Bioprocess Technol 15:2646–2663

Özyurt G, Uslu L, Yuvka I, Gökdoğan S, Atci G, Ak B, Işik O (2015) Evaluation of the cooking quality characteristics of pasta enriched with Spirulina platensis. J Food Qual 38:268–272

Plaza BM, Gómez-Serrano C, Acién-Fernández FG, Jimenez-Becker S (2018) Effect of microalgae hydrolysate foliar application (Arthrospira platensis and Scenedesmus sp.) on Petunia x hybrida growth. J Appl Phycol 30:2359–2365

Puglisi I, La Bella E, Rovetto EI, Lo Piero AR, Baglieri A (2020) Biostimulant effect and biochemical response in lettuce seedlings treated with a Scenedesmus quadricauda extract. Plants 9:123

Puglisi I, La Bella E, Rovetto EI, Stevanato P, Fascella G, Baglieri A (2022) Morpho-biometric and biochemical responses in lettuce seedlings treated by different application methods of Chlorella vulgaris extract: foliar spray or root drench? J Appl Phycol 34:889–901

Qazi WM, Ballance S, Uhlen AK, Kousoulaki K, Haugen J-E, Rieder A (2021) Protein enrichment of wheat bread with the marine green microalgae Tetraselmis chuii – Impact on dough rheology and bread quality. LWT 143:111115

Refaay DA, El-Marzoki EM, Abdel-Hamid MI, Haroun SA (2021) Effect of foliar application with Chlorella vulgaris, Tetradesmus dimorphus, and Arthrospira platensis as biostimulants for common bean. J Appl Phycol 33:3807–3815

Rodrigues RDP, de Lima PF, de Santiago-Aguiar RS, Rocha MVP (2019) Evaluation of protic ionic liquids as potential solvents for the heating extraction of phycobiliproteins from Spirulina (Arthrospira) platensis. Algal Res 38:101391

Rouphael Y, Colla G (2018) Synergistic biostimulatory action: Designing the next generation of plant biostimulants for sustainable agriculture. Front Plant Sci 9:01655

Sánchez-Zurano A, Morillas-España A, González-López CV, Lafarga T (2020) Optimisation of protein recovery from Arthrospira platensis by ultrasound-assisted isoelectric solubilisation/precipitation. Processes 8:1586

Schagerl M, Siedler R, Konopáčová E, Ali SS (2022) Estimating biomass and vitality of microalgae for monitoring cultures: A roadmap for reliable measurements. Cells 11:2455

Shah MR, Lutzu GA, Alam A, Sarker P, Chowdhury MAK, Parsaeimehr A, Liang Y, Daroch M (2018) Microalgae in aquafeeds for a sustainable aquaculture industry. J Appl Phycol 30:197–213

Taragjini E, Ciardi M, Musari E, Villaro S, Morillas-Espana A, Alarcon FJ, Lafarga T (2022) Pilot-scale production of A. platensis: Protein isolation following an ultrasound-assisted strategy and assessment of techno-functional properties. Food Bioprocess Technol 15:1299–1310

Villaró S, Morillas-España A, Acién G, Lafarga T (2022a) Optimisation of operational conditions during the production of Arthrospira platensis using pilot-scale raceway reactors, protein extraction, and assessment of their techno-functional properties. Foods 11:2341

Villaró S, Sánchez-Zurano A, Ciardi M, Alarcón FJ, Clagnan E, Adani F, Morillas-España A, Álvarez C, Lafarga T (2022b) Production of microalgae using pilot-scale thin-layer cascade photobioreactors: Effect of water type on biomass composition. Biomass Bioenerg 163:106534

Zen CK, Tiepo CBV, da Silva RV, Reinehr CO, Gutkoski LC, Oro T, Colla LM (2020) Development of functional pasta with microencapsulated Spirulina: technological and sensorial effects. J Sci Food Agric 100:2018–2026

Zhao M, Lin Y, Chen H (2020) Improving nutritional quality of rice for human health. Theor Appl Genet 133:1397–1413

Funding

Funding for open access publishing: Universidad de Almería/CBUA. This work forms part of the project ALGAL·FOOD (UAL2020-AGR-A1945) funded by the Government of Andalusia and by the European Regional Development fund “ERDF A way of making Europe” and the project CLEAN·AIR (TED2021-131511A-I00), funded by MCIN/AEI/10.13039/501100011033 and European Union NextGenerationEU/PRTR. Tomás Lafarga would like to thank the Ramon y Cajal Programme (RYC2021-031061-I) funded by MCIN/AEI/10.13039/501100011033 and European Union NextGenerationEU/PRTR.

Author information

Authors and Affiliations

Contributions

S. Villaró: Investigation, formal analysis, writing – original draft; G. Acién: Supervision, funding acquisition, project administration; J. Alarcón: Formal analysis; A. Ruiz: Investigation; L. Rodríguez-Chikri: Investigation; E. Viviano: Investigation, formal analysis; T. Lafarga: Supervision, funding acquisition, project administration.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Villaró, S., Acién, G., Alarcón, J. et al. A zero-waste approach for the production and use of Arthrospira platensis as a protein source in foods and as a plant biostimulant in agriculture. J Appl Phycol 35, 2619–2630 (2023). https://doi.org/10.1007/s10811-023-02993-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-023-02993-2