Abstract

Rhodomonas salina is a microalgal species, belonging to the cryptophytes, and is widely used as aquaculture feed because of its high nutritional profile and phycoerythrin content. This study investigated the effect of pH on the growth, biochemical composition, and taste of R. salina when cultivated on a semi-large scale under natural light conditions. Two tubular photobioreactors (200 L) were used for the cultivation of R. salina with sunlight as the only illumination source. Two different pH setpoints were applied, 7 and 8.5. Optimal temperature and nutrient conditions were applied, according to previous research findings. The results demonstrated that the productivity of R. salina was higher at pH 7, 0.06–0.14 gdry weight L−1 day−1, compared to pH 8.5, 0.03–0.12 gdry weight L−1 day−1. It was found that protein and total fatty acid concentrations were higher in the biomass that was produced at pH 8.5, 33.7% and 12.3% of dry weight, respectively, while at pH 7, the protein content was 31.9% and the total fatty acids 8.8% of dry weight. The phycoerythrin concentration, like protein, was higher at pH 8.5, 2.7% of dry weight, compared to pH 7, 1% of dry weight. The free amino acid and nucleotide profile of R. salina was affected by the pH, resulting in increased equivalent umami concentration at pH 7. For the sensory evaluation, an expert panel on algae flavors evaluated the effect of pH on the taste of R. salina, reporting that the biomass that was produced at pH 7 had more umami flavor than the biomass that was produced at pH 8.5, which was evaluated as more bitter.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The United Nations reported that “Food production must double by 2050 to meet demand from world’s growing population” (United Nations 2017). However, food production is responsible for 26% of global greenhouse gas emissions (Poore and Nemecek 2018). Microalgae have illustrated the potential to meet the need for more sustainable food production, especially after taking into account their ability to capture CO2 and reduce the environmental impact (Caporgno and Mathys 2018).

Rhodomonas salina (Cryptophyceae) is of great importance in aquaculture because of its lipid profile and phycoerythrin concentration (Guevara et al. 2011; Gonzalez Araya et al. 2012; Arndt and Sommer 2014). Most aquatic animals are not able to synthesize polyunsaturated fatty acids (PUFA) which are crucial for their growth and development (Kanazawa et al. 1979; Langdon and Waldock 1981; Gonzalez Araya et al. 2012). Rhodomonas salina is an excellent feed because of its relatively high PUFA levels (> 60% of total fatty acids) and the combination of eicosapentaenoic acid (EPA 20:5n-3, 8% of total fatty acids) and docosahexaenoic acid (DHA 22:6n-3, 3–7% of total fatty acids) (Renaud et al. 1999; Seixas et al. 2009; Coutinho et al. 2020). The increased growth and larvae survival are attributed to the increased concentrations of EPA and DHA in their diets (Thompson et al. 1993; Helm and Bourne 2004; Brown and Blackburn 2013). Moreover, there are many studies that correlate the DHA to EPA ratio with the increased performance of larvae (Rodríguez et al. 1997, 1998; Pettersen et al. 2010).

Microalgae can enhance the nutritional value of the human diet with many health-promoting metabolites, such as fatty acids, amino acids, pigments, and antioxidants (Sathasivam et al. 2019). In the last 30 years, many research groups and companies have invested significant amounts of time and money to commercialize the production of microalgae (Chacón-Lee and González-Mariño 2010; Koyande et al. 2019). Despite this high interest in microalgae, they have not yet met the expectations as a major food source.

One of the bottlenecks in the commercialized production of microalgae is the high production cost. Most research that has been conducted in recent years has been carried out on a laboratory scale under constant, controlled conditions. The transition from laboratory to commercial scale production needs to be studied in detail. Norsker et al. (2011) reported that in tubular photobioreactors, a photosynthetic efficiency increase from 3 to 5% can lead to a 35% reduction of the production cost. The cost of pure CO2 injection represents from 39 up to 71% of the raw material cost, after taking into account the availability of the CO2 and the separation from flue gas (Acién et al. 2012). In tubular photobioreactors, CO2 cost is estimated up to 2.7 € kg−1 of dry weight, while in raceway ponds, it can reach 4.6 € kg−1 of dry weight, due to the poor CO2 fixation performance of microalgae in open systems (Norsker et al. 2011; Slade and Bauen 2013).

The taste, color, odor, and texture of microalgae biomass have been identified as another potential bottleneck for the use of microalgae in food products. Therefore, currently most commercialized products of microalgae are available as food supplements in the forms of tablets and capsules, or mixed with other products, such as pastes, pasta, or beverages to mask their flavor (Yamaguchi 1996; Liang et al. 2004; Pulz and Gross 2004). Microalgae pigments can also be used in the food industry. For instance, phycocyanin has been used as additive in biscuits and beverages (Dufossé et al. 2005; Koyande et al. 2019). Phycoerythrin, which is a red, water-soluble phycobiliprotein, can serve as a natural colorant in food, gelatin desserts, and dairy products (Dufossé et al. 2005).

We recently showed that R. salina is rich in umami flavor, according to the estimated equivalent umami concentration (EUC), which is affected by pH and salinity changes (Latsos et al. 2021a, b). As the next step, this study aims to demonstrate the semi-large scale production of R. salina under sunlight conditions and to investigate the effect of pH on biomass productivity, biochemical composition, and taste. Two different pH setpoints were applied, 7 and 8.5. At pH 7, R. salina has previously shown optimal growth on small scale, while at pH 8.5, the highest EUC was obtained for R. salina (Latsos et al. 2021a, b).

Materials and methods

Strain and pre-culture

The marine cryptophyte Rhodomonas salina CCMP1319 was supplied by the Dutch aquaculture industry and pre-cultured in pre-sterilized (20 min at 120 °C) 300 mL Erlenmeyer flasks in 10 times concentrated nutrients of filtered (0.2 μm pore size) f/2 medium (Guillard and Hargraves 1993) with a salinity of 30 g L−1. Cultures were continuously illuminated at a photon flux density (PFD) of 120 µmol photons m−2 s−1 provided by cool white fluorescent tubes. The temperature in the incubator was maintained at 20 ± 1 °C and air enriched with 5% CO2 v/vair was supplied in the headspace of the Erlenmeyer flasks.

Experimental setup

Two tubular photobioreactors (LGem MK1-200, LGem, the Netherlands) were used for R. salina cultivation, located in Vlissingen, the Netherlands (Fig. 1). An air pump with a 4 L min−1 filtered airflow (2 and 0.2 μm pore size) was responsible for the recirculation of the culture in the reactor. The pH was maintained at 7.1 ± 0.3 and 8.5 ± 0.3 for each reactor, respectively, by on-demand CO2 addition in the airflow of the reactor. The temperature of both reactors was maintained at 21 ± 1 °C by recirculation of hot or cold water over a heat exchanger in the reactor tank. The water was provided by a heat pump (30RQ 017 CHE, Carrier, the Netherlands). Sunlight was the only source of light and was measured by photosynthetically active radiation (PAR) sensor on top of the reactors. The temperature, pH, and light intensity were measured online by a reactor control system (APEX, Fusion, Neptune Systems, USA).

The photobioreactors were operated in chemostat mode with a dilution of 5.5 ± 0.5 L h−1. Dilution took place only for the period when the sunlight was illuminating the reactors, being approximately 11 to 14 h per day, corresponding to a dilution rate of 0.30–0.42 day−1. The dilution was in line with previous research on cultivation of Rhodomonas in outdoor conditions (Oostlander et al. 2020a). The dilution was performed with filtered (0.5 μm and 0.2 μm—SupaPleat Plus, Amazon Filters, UK) saline groundwater with the addition of adequate levels of nutrients by peristaltic pumps. After the addition of nutrients, the groundwater was equal to 10 times concentrated f/2 medium. The photobioreactors were operated from April till July in multiple reactor runs.

Daily measurements

Daily samples were taken from each photobioreactor for the measurement of optical and cell density. The optical density was measured at 750 nm (OD750nm), from which biomass concentration (Cx) was calculated according to Oostlander et al. (2020b). The cell density was measured in Coulter Counter (Multisizer 3, Beckman Coulter, USA) in the size range 7–14 μm.

During the chemostat mode, the volumetric biomass productivity (rx) was calculated in g L−1 day−1 according to Eq. 1, where \({V}_{H}\) is the harvested volume between two measurements in a \(\Delta t\) period of time and \({V}_{R}\) the reactor volume.

Cell composition

The R. salina biomass was harvested from the growth medium using the Membrane Algae Filtration (MAF) technology (VITO, Belgium) (Fig. 2). The MAF technology is a submerged membrane filtration (UF membranes) approach where permeate (water and salts) is removed via under pressure resulting in low shear forces on the algal biomass. The latter aspect allows harvesting of fragile cells without inducing cell disruption. The MAF was operated in continuous mode following the dilution rate described in “Experimental setup” section. Each 2–3 days, after dewatering (volume concentration factors up to 100 were reached), the cells were desalted with the MAF till the electric conductivity (EC) was reduced from 38–42 mS cm−1 till below 1–2 mS cm−1. The desalted biomass was subsequently freeze-dried (Christ, gamma 1–16 LSC).

Cell disruption was performed in a sonication bath. Subsequently, protein content was determined by the Folin method (Lowry et al. 1951). Fatty acids (FA) were extracted and quantified according to Breuer et al. (2012). The lipids were extracted using a chloroform: methanol (1:1.25 v/v) mixture and methylated in a MeOH solution containing 5% H2SO4 for 3 h at 70 °C in a block heater. The fatty acid methyl esters (FAME) were analyzed and quantified by means of gas chromatography mass spectrometry using a Thermo Finnigan TraceGC ultra system/DSQ equipped with a SGE Analytical Science BPX70 column (50 m × 0.32 mm; 0.25 \(\mu \mathrm{m})\) with helium as carrier gas. FAME were identified based on retention time data of known standards. Heptadecanoic triacylglycerol (C17:0 TAG) was added as the internal standard for fatty acid quantification. Total fatty acids (TFA) were calculated as the sum of all individual fatty acids. FA were also expressed as saturated fatty acids (SFA), monounsaturated fatty acids (MFA), PUFA, and DHA/EPA ratio.

Phycoerythrin was extracted in phosphate buffer by a freeze-thawing process, centrifuged (10 min at 2500 rpm), and analyzed using UV–vis spectroscopy according to Bennett and Bogarad (1973; Lawrenz et al. 2011). Equation 2 was used for the calculation of phycoerythrin (Lawrenz et al. 2011).

where A is the absorbance at 545 nm after scatter corrected by subtracting the absorbance at 750 nm, ε is the molar extinction coefficient of phycoerythrin (2.41 × 106 L mol−1 cm−1), MW is the molecular weight of phycoerythrin (240,000 g mol−1), d is the path length in cm, and Vsample and Vbuffer are the volumes of the sample and the buffer, respectively.

Free amino acids (FAA) and nucleotides were extracted and analyzed according to Moerdijk-Poortvliet et al. (2022). In brief, 15 mg of biomass and 5 mL Milli-Q were homogenized and extracted for 15 min at 35 °C followed by centrifugation (3000 rpm, 20 min). A 3 mL sample of supernatant was taken and an acid precipitation step with 600 µL of 37% HCl was performed to remove contaminants. For FAA, an additional purification step was performed using DOWEX 50WX8 cation exchange resin. FAA and nucleotide samples were analyzed by means of high-performance liquid chromatography (HPLC) using a DIONEX Ultimate 3000 HPLC system. For FAA analysis, the HPLC was equipped with an Agilent InfinityLab Poroshell 120 HPH-C18 column (100 × 4.6 mm; 2.7 µm), matching guard column (5 × 4.6 mm; 2.7 µm), and a fluorescence detector (FLD 3100). For nucleotide analysis, the HPLC was equipped with a SIELC PrimeSep D mixed-mode column (150 × 4.6 mm; 5 µm) with a corresponding guard column (10 × 4.6 mm; 5 µm) and an ultraviolet detector (DAD 3000).

Taste activity value and EUC

The contribution of FAA and nucleotides to the overall taste was evaluated with the determination of their taste activity value (TAV). The TAV was calculated as reported by Kato et al. (1989) according to the following equation:

where C1 is the concentration of the taste compounds in mg g−1 dry weight, and C2 is the threshold concentration in mg g−1 dry weight, the minimum concentration at which a taste compound can be perceived. When the TAV is more than 1, it is considered that the compound contributes to the overall taste. The taste threshold concentrations that were used are based on Duan et al. (2020).

The umami estimation can be determined based on the concentration of monosodium glutamate (mg MSG g−1), which is equivalent to the umami intensity. The synergy effect between the mixture MSG-like AAs and 5′-nucleotides is represented by Eq. 4 (Yamaguchi et al. 1971):

where Y is the EUC (mg MSG g−1); \({a}_{i}\) is the concentration (mg g−1) of each umami AA (aspartic or glutamic acid); \({a}_{j}\) is the concentration (mg g−1) of each umami 5′-nucleotide, inosine 5′-monophosphate (IMP), guanosine 5′-monophosphate (GMP), or adenosine 5′-monophosphate (AMP); \({b}_{i}\) is the relative umami concentration (RUC) for each umami AA to MSG (1 for glutamic acid, and 0.077 for aspartic acid); and \({b}_{j}\) is the RUC for each umami 5′-nucleotide to IMP (1 for IMP, 2.3 for GMP, and 0.18 for AMP). 12.18 is the synergistic constant based on the concentration of mg g−1 used.

Ethical approval

All algae samples, meant for the expert panel, were evaluated on chemical safety, including cadmium (Cd), lead (Pb), mercury (Hg), total and inorganic arsenic (As) and iodine (I), and tested for pathogens, including Staphylococcus aureus, Escherichia coli, Salmonella, Listeria spp., Listeria monocytogenes, yeast, and molds. Prior to tasting, the safety results were evaluated and approved by the ethical standards of the committee responsible for human experimentation (ECSG-ILVO board).

Sensory evaluation

Descriptive sensory analyses on the algae were performed using an internally trained expert panel on algae flavors. The panel consisted of 8 assessors who are able to distinguish basic tastes and specific taste attributes for R. salina. Training of the selected panelists was performed according to ISO8586, by which they were familiarized with the following characteristic tastes: (1) salt; (2) bitter; (3) umami; (4) seafood taste (crab); and (5) earthy (beetroot) taste (Table 1). These tastes were selected and scored using a scale ranging from 0 (absent) to 10 (very strong). Samples were prepared by homogenizing 10 g freeze-dried R. salina in 1 L of bottled water (crystalline). Fresh R. salina solutions were presented to each panelist in randomly coded and closed 20 mL screw-capped amber colored glass vials.

Data analysis and statistics

Analysis of covariance (ANCOVA) was applied to the productivity data for the comparison of productivity regression lines over light intensity. All the cell composition data and the sensory evaluation results were analyzed by multiple t-tests to determine whether pH has a significant effect on the cellular composition of R. salina. Statistical analysis was performed using SPSS 25.0 statistical package (SPSS Inc., USA) and Prism 8.0.2 (GraphPad, USA).

Results

Productivity

Rhodomonas salina had higher daily productivity at pH 7 compared to pH 8.5 (Fig. 3). At pH 7, the productivity was increased in line with the increase of the light intensity, ranging from 0.055 to 0.137 g L−1 day−1, in low and high light intensity, respectively. At pH 8.5, the increase of light intensity did not influence the productivity, which varied from 0.034 to 0.120 g L−1 day−1. The regression lines of the datasets of the two different pH setpoints did not show any significant difference (p = 0.104). It is worth mentioning that there was no productivity data at pH 8.5 in light intensities higher than 33 mol photons m−2 day−1. In these light intensities, the algal biomass in the reactor collapsed.

Cellular composition

The cellular composition of R. salina was examined from the biomass that was produced by the photobioreactors after going through the downstream steps that are mentioned in “Materials and methods.” The protein concentration of the R. salina biomass produced at pH 8.5 was significantly higher than the protein concentration at pH 7, 33.7 ± 0.6% and 31.9 ± 0.2% of the dry weight, respectively (p = 0.02) (Fig. 4A). A similar increase was observed at the phycoerythrin content of R. salina. At pH 8.5, the phycoerythrin concentration was 2.7% of dry weight, while at pH 7, the phycoerythrin concentration was 1% of dry weight (Fig. 4B). Due to the limited samples (n = 3), this difference was not statistically significant (p = 0.13).

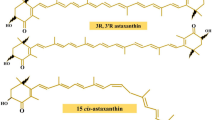

The main fatty acids of R. salina cultivated in both pH setpoints were α-linolenic (18:3n-3), stearidonic (18:4n-3), palmitic (16:0), and linoleic (18:2n-6) (Table 2). However, at pH 8.5, R. salina had higher TFA concentration, 12.3% of dry weight, compared to pH 7, 8.8% of dry weight (Fig. 5A). This is a result of increased concentration of saturated, unsaturated, and polyunsaturated fatty acids at pH 8.5. EPA and DHA are also increased at pH 8.5, 0.8% and 0.3% of dry weight, respectively, compared to pH 7, 0.6% and 0.2% of dry weight (Fig. 5B). The DHA to EPA ratio was not significantly different between the two pH setpoints, 0.34 at pH 7 and 0.36 at pH 8.5.

Taste active value and equivalent umami concentration

The main free amino acids extracted from R. salina were the L-proline, L-glutamic acid, and L-arginine (Table 3). The biomass cultivated at pH 7 had a significantly higher concentration of L-aspartic acid and L-asparagine than at pH 8.5. Rhodomnas salina grown at pH 8.5 showed significantly increased concentrations of L-serine, L-glutamine, L-arginine, and L-leucine. The total free amino acid concentration was higher at pH 8.5 in comparison with pH 7, 4.28 and 3.88 mg g−1 dry weight, respectively (p = 0.038). L-glutamic acid was the only FAA with TAV greater than 1 in the biomass that was produced at pH 7. At pH 8.5, there were two FAA with TAV higher than 1, L-glutamic acid and L-arginine.

All the free nucleotides were significantly increased at pH 7 compared to pH 8.5, except for AMP, which was stable under both pH conditions (Table 4). The increased nucleotide concentration at pH 7, in combination with the increased aspartic and glutamic acid concentration, led to significantly increased equivalent umami concentration, 136 mg MSG g−1 of dry weight, compared to 78 mg MSG g−1 dry weight at pH 8.5.

Sensory evaluation

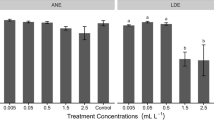

Rhodomonas salina biomass that was produced at pH 7 was evaluated by the taste panel with significantly higher umami taste (Fig. 6). Rhodomonas salina that was cultivated at pH 8.5 was characterized by a more bitter and earthy taste. Other attributes did not show any significant differences in the evaluation.

Descriptive taste panel results of R. salina cultivated at pH 7 (dark grey) and pH 8.5 (light grey). These tastes were scored using a scale ranging from 0 (absent) to 10 (very strong). (*Indicates the significant difference after t-test of pairwise comparison between the pH setpoints *p < 0.05, **p < 0.01)

Discussion

Productivity

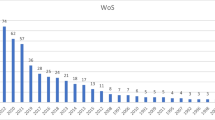

This study investigated the influence of pH in the growth, biochemical composition, and taste of R. salina which was successfully cultivated on a semi-large scale under natural sunlight conditions with productivity varying from 0.034 to 0.137 g L−1 day−1. The highest productivity that has been reported in continuous culture for R. salina is 1.17 g L−1 day−1 (Latsos et al. 2021a). However, it is noteworthy that this high productivity was obtained in a small scale system (0.4 L) and under constant artificial light conditions and 24 h light per day. The productivity values obtained in our current study are in line with the values that have been reported in the literature for R. salina cultivation in tubular photobioreactors (Oostlander et al. 2020a; Thoisen et al. 2020). Oostlander et al. (2020a) obtained higher productivity values (0.1–0.19 g L−1 day−1) for Rhodomonas sp., compared to this study, under sunlight conditions, which is the result of higher biomass concentration in the reactors. Thoisen et al. (2020) reported productivity values 0.02–0.1 g L−1 day−1 for light intensities of 8.6–21 mol photons m−2 day−1 of artificial light.

The productivity of R. salina was higher at pH 7 in comparison with pH 8.5. This result is analogous to the literature, in which many studies have been reported pH 7 as the optimal for the growth and the production rate of Rhodomonas (Berge et al. 2010; Latsos et al. 2021a). At pH 8.5, the productivity was lower, while in high light intensities (> 35 mol photons m−2 day−1), the biomass in the reactor collapsed. This lower productivity and instability of the reactor at pH 8.5 can be explained by the limited availability of CO2 (Chenl and Durbin 1994). Latsos et al. (2021a, b) and Hansen (2002) illustrated in their studies that the growth of R. salina is reduced at pH 8.5 and 9. At high pH conditions, the concentration of reactive oxygen species (ROS) is also increased, which can overcome the antioxidant defenses of the cells and increase the possibility of cell damage (Liu et al. 2007).

Cellular composition

The cell composition of R. salina was affected by the different pH’s at which it was cultivated. The protein concentration was higher at pH 8.5, which is in line with the literature. Qiu et al. (2017) reported higher protein content in Chlorella sorokiniana biomass produced at higher pH. Similar findings for higher protein concentration at higher pH have been observed for Spirulina sp. (Ogbonda et al. 2007). However, Dunaliella salina presented lower protein concentration in higher pH (Sui and Vlaeminck 2019). The higher protein content at pH 8.5 can be explained by the higher phycoerythrin content. Phycoerythrin constitutes 12 to 20% of the total protein content (Seixas et al. 2009; Barka and Blecker 2016). The increased phycoerythrin concentration at pH 8.5 is in line with previous literature on R. salina (Latsos et al. 2021a). This increase of phycoerythrin can be associated with the antioxidant activity of the pigment as a response to the ROS increase at alkaline conditions (Samarakoon and Jeon 2012; Jung et al. 2016; Gauthier et al. 2020).

The cellular protein content of Rhodomonas species varies from 30 to more than 50%, depending on the culture conditions (Renaud et al. 1999; Seixas et al. 2009; Yamamoto et al. 2020). In this study, the protein concentration is lower compared to the literature values. Phycoerythrin concentration of this study is also lower than the reported values in the literature (Seixas et al. 2009; Yamamoto et al. 2020; Latsos et al. 2021b, a). This phenomenon may be explained by the harvesting and desalting steps of our current experiment. In previous studies, it was reported that the experiments were conducted on a laboratory scale and the biomass processing steps did not take as long as the desalting step of our study. Processing of the R. salina biomass took several hours, during which time phycoerythrin/protein losses were sometimes observed at the end of the diafiltration. Not only the harvesting and drying steps but also the storage can affect the quality of the biomass (de Farias Neves et al. 2020; Verspreet et al. 2020; Castro-muñoz 2021). The impact of subsequent freezing and freeze-drying, especially on phycoerythrin, required further attention and loss of colors has been observed in some occasions. Marcati et al. (2014) investigated the recovery of B-phycoerythrin from Porphyridium using a pilot scale filtration unit, achieving up to 48% recovery of the phycobiliprotein. The microalgal cells may break during the harvesting step in pilot scale, due to the shear force of centrifuge or filtration. However, this did not happen in our experiment and the cells remained intact after the filtration step. The biomass staying out of the culture conditions, such as lower salinity and temperature, and no pH control, could explain the loss of pigmentation and consequently the lower protein concentration. By using a MAF filtration device which capacity is tailored to harvested amounts (for instance, smaller MAF or higher harvested amounts), the dewatering and desalting time can be reduced.

The major fatty acids of R. salina cultivated in both pH setpoints were α-linolenic (18:3n-3), stearidonic (18:4n-3), palmitic (16:0), and linoleic (18:2n-6) acids. This observation is in line with the literature results for Rhodomonas species (van Houcke et al. 2017; Coutinho et al. 2020; Latsos et al. 2020). The increase of the pH from 7.0 to 8.5 induced a 1.4-fold increase of SFA, MUFA, and PUFA of R. salina. There is extensive literature that supports the increase of the lipid content in many microalgae with the increase of pH. For instance, Tisochrysis lutea, Chlamydomonas reinhardtii, and Chlorella sp. increased their lipid content, especially the PUFA concentration, as a defense mechanism against the alkaline pH stress (Paliwal et al. 2017; Ochoa-Alfaro et al. 2019; Almutairi et al. 2020).

Taste active value and equivalent umami concentration

The main free amino acids in R. salina were L-proline, L-glutamic acid, and L-arginine. These results are in agreement with the literature for R. salina (Seixas et al. 2009; van Houcke et al. 2017; Latsos et al. 2021a). The increase of pH appears to positively affect the total free amino acid concentration, a finding that has been observed previously (Latsos et al. 2021a). However, the free 5′-nucleotide concentration, and therefore the EUC, was significantly higher at pH 7. This contradicts the study of Latsos et al. (2021a) in which the EUC showed a peak at pH 8.5. There is lack of knowledge on how microalgae change their free amino acid and nucleotide profile as a reaction to changes in cultivation conditions. An explanation might be the scale difference of the experiment, considering that the research of Latsos et al. (2021a) was conducted in 400 mL photobioreactors. There is extensive literature on how scale-up can affect the composition of microalgae (Torzillo and Vonshak 2013; da Silva and Reis 2015; Borowitzka 2016; Borowitzka and Vonshak 2017). In our study, the sunlight was used as only illumination source and, as a result, the light intensity was not stable compared to the laboratory experiment. The fact that in the outdoor scale-up culture, the illumination is not continuous but has a day/night period can affect circadian rhythms and biological functions such as photosynthesis, pigments synthesis, and nitrogen fixation (Corellou et al. 2009; Sorek et al. 2013; Braun et al. 2014). Another explanation could be the desalting step, which took longer in this study than at laboratory scale, and the biomass might overstayed in low salinity, resulting to osmoregulation and changes in biochemical composition.

Sensory evaluation

The expert panel associated the changes in free amino acid and nucleotide profile with the taste of R. salina. The biomass that was produced at pH 7 was evaluated with a higher umami taste than the biomass that was produced at pH 8.5. This result is in accordance with the EUC that was calculated and can be explained by the higher L-aspartic acid, L-glutamic acid, GMP, IMP, and AMP at pH 7. Rhodomonas salina cultivated at pH 8.5 was characterized as more bitter than at pH 7. The bitterness may be attributed to the increased L-arginine, L-leucine, L-tryptophan, and L-tyrosine, amino acids that are associated with the bitter taste (Kato et al. 1989; Nishimura and Kato 2009). Specifically, the TAV of L-arginine was greater than 1 at pH 8.5, while at pH 7, it was 0.7. The increased fatty acid concentration at pH 8.5 may have some effect on the bitter taste as well. For instance, linoleic acid, which is 1.3 times higher in R. salina at pH 8.5, is associated with a bitter flavor (Ledahudec and Pokorný 1991; Khan et al. 2019). Moreover, microalgae under pH stress are known to accumulate polyphenols (Gauthier et al. 2020). These molecules, even though not measured in our study, may also explain the bitter taste at pH 8.5 because bitterness is a major sensory attribute of several common foods and beverages rich in polyphenol compounds (Drewnowski and Gomez-Carneros 2000; Soares et al. 2013).

Conclusion

In this study, R. salina was successfully cultivated on semi-large scale (200 L) at two different pH setpoints, under natural sunlight conditions. The productivity was in general agreement with previous research at the pilot laboratory scale. Our results show that the increase of pH from 7 to 8.5 has a significant effect on the productivity and the quality of R. salina. The productivity was higher at pH 7 than at pH 8.5. However, there is still potential for improvement of the (semi-)large scale production after considering the higher productivity values obtained at the laboratory scale and indoor conditions. The increase of pH to 8.5 induced the accumulation of lipids and phycoerythrin as a response to the pH stress. The change of the quality of R. salina due to pH settings affected the taste of the biomass, characterized by a higher umami taste at pH 7 and a higher bitter taste at pH 8.5. Our study provides the framework for future studies to assess the connection of the biomass composition of microalgae with their taste.

Another aspect of the study was to observe how the quality of R. salina can be manipulated. In many cases, contradictory conditions are required for the production of biomass and synthesis of target metabolites. The cultivation of microalgae in two distinct stages can offer a solution to this problem. In the first step, optimal growth conditions are provided to achieve high biomass productivities. This step is followed by the second stage, where cells are exposed to stress conditions in order to accumulate target metabolites.

Availability of data and material

Full data is available after a request of the reviewers.

References

Acién FG, Fernández JM, Magán JJ, Molina E (2012) Production cost of a real microalgae production plant and strategies to reduce it. Biotechnol Adv 30:1344–1353

Almutairi AW, El-Sayed AEKB, Reda MM (2020) Combined effect of salinity and pH on lipid content and fatty acid composition of Tisochrysis lutea. Saudi J Biol Sci 27:3553–3558

Arndt C, Sommer U (2014) Effect of algal species and concentration on development and fatty acid composition of two harpacticoid copepods, Tisbe sp. and Tachidius discipes, and a discussion about their suitability for marine fish larvae. Aquac Nutr 20:44–59

Barka A, Blecker C (2016) Microalgae as a potential source of single-cell proteins. A review. Biotechnol Agron Soc Environ 20:427–436

Bennett A, Bogarad L (1973) Complementary chromatic adaptation in a filamentous blue-green alga. J Cell Biol 58:419–435

Berge T, Daugbjerg N, Andersen BB, Hansen PJ (2010) Effect of lowered pH on marine phytoplankton growth rates. Mar Ecol Prog Ser 416:79–91

Borowitzka MA (2016) Algal physiology and large-scale outdoor cultures of microalgae. In: Borowitzka MA, Beardall J, Raven JA (eds) The physiology of microalgae. Springer, Cham, pp 601–652

Borowitzka MA, Vonshak A (2017) Scaling up microalgal cultures to commercial scale. Eur J Phycol 52:407–418

Braun R, Farré EM, Schurr U, Matsubara S (2014) Effects of light and circadian clock on growth and chlorophyll accumulation of Nannochloropsis gaditana. J Phycol 50:515–525

Breuer G, Lamers PP, Martens DE, Draaisma RB, Wijffels RH (2012) The impact of nitrogen starvation on the dynamics of triacylglycerol accumulation in nine microalgae strains. Bioresour Technol 124:217–226

Brown MR, Blackburn SI (2013) Live microalgae as feeds in aquaculture hatcheries. In: Allan G, Bunnell G (eds) Advances in aquacultuer hatchery technology. Woodhead Publishing, Oxford, pp 117–156

Caporgno MP, Mathys A (2018) Trends in microalgae incorporation into innovative food products with potential health benefits. Front Nutr 5:58

Castro-Muñoz R (2021) Membrane-based harvesting processes for microalgae and their valuable-related molecules: a review. 1–21

Chacón-Lee TL, González-Mariño GE (2010) Microalgae for “healthy” foods-possibilities and challenges. Compr Rev Food Sci Food Saf 9:655–675

Chenl CY, Durbin EG (1994) Effects of pH on the growth and carbon uptake of marine phytoplankton. Mar Ecol Prog Ser 109:83–94

Corellou F, Schwartz C, Motta J-P, Djouani-Tahri EB, Sanchez F, Bouget F-Y (2009) Clocks in the green lineage: comparative functional analysis of the circadian architecture of the picoeukaryote Ostreococcus. Plant Cell 21:3436–3449

Coutinho P, Ferreira M, Freire I, Otero A (2020) Enriching rotifers with “premium” microalgae: Rhodomonas lens. Mar Biotechnol 22:118–129

da Silva TL, Reis A (2015) Scale-up problems for the large scale production of algae. In: Das D (ed) Algal biorefinery: an integrated approach. Springer, Cham, pp 125–149

de Farias Neves F, Demarco M, Tribuzi G (2020) Drying and quality of microalgal powders for human alimentation. In: Vitova M (ed.) Microalgae - From Physiology to Application. IntechOpen. https://doi.org/10.5772/intechopen.89324

Drewnowski A, Gomez-Carneros C (2000) Bitter taste, phytonutrients, and the consumer: a review. Am J Clin Nutr 72:1424–1435

Duan W, Huang Y, Xiao J, Zhang Y, Tang Y (2020) Determination of free amino acids, organic acids, and nucleotides in 29 elegant spices. Food Sci Nutr 8:3777–3792

Dufossé L, Galaup P, Yaron A et al (2005) Microorganisms and microalgae as sources of pigments for food use: a scientific oddity or an industrial reality? Trends Food Sci Technol 16:389–406

Gauthier MR, Senhorinho GNA, Scott JA (2020) Microalgae under environmental stress as a source of antioxidants. Algal Res 52:102104

Gonzalez Araya R, Mingant C, Petton B, Robert R (2012) Influence of diet assemblage on Ostrea edulis broodstock conditioning and subsequent larval development. Aquaculture 364–365:272–280

Guevara M, Bastardo L, Cortez R, Arredondo-Vega B, Romero L, Gómez P (2011) Rhodomonas salina (Cryptophyta) pastes as feed for Brachionus plicatilis (Rotifera). Rev Biol Trop 59:1503–1515

Guillard RRL, Hargraves PE (1993) Stichochrysis immobilis is a diatom, not a chrysophyte. Phycologia 32:234–236

Hansen PJ (2002) Effect of high pH on the growth and survival of marine phytoplankton: implications for species succession. Aquat Microb Ecol 28:279–288

Helm M, Bourne N (2004) Hatchery culture of bivalves. FAO Fish Tech Pap 201

Jung SM, Park JS, Shim HJ, Kwon YS, Kim HG, Shin HS (2016) Antioxidative effect of phycoerythrin derived from Grateloupia filicina on rat primary astrocytes. Biotechnol Bioprocess Eng 21:676–682

Kanazawa A, Teshima SI, Ono K (1979) Relationship between essential fatty acid requirements of aquatic animals and the capacity for bioconversion of linolenic acid to highly unsaturated fatty acids. Comp Biochem Physiol B 63:295–298

Kato H, Rhue MR, Nishimura T (1989) Role of free amino acids and peptides in food taste. In: Teranishi R, Buttery RG, Shahidi F (eds.) Flavor Chemistry. ACS, Washington pp 158–174

Khan AS, Murtaza B, Hichami A, Khan NA (2019) A cross-talk between fat and bitter taste modalities. Biochimie 159:3–8

Koyande AK, Chew KW, Rambabu K, Tao Y, Chu D-T, Show P-L (2019) Microalgae: a potential alternative to health supplementation for humans. Food Sci Hum Wellness 8:16–24

Langdon CJ, Waldock MJ (1981) The effect of algal and artificial diets on the growth and fatty acid composition of Crassostrea gigas spat. J Mar Biol Assoc U K 61:431–448

Latsos C, van Houcke J, Timmermans KR (2020) The effect of nitrogen starvation on biomass yield and biochemical constituents of Rhodomonas sp. Front Mar Sci 7:563333

Latsos C, Bakratsas G, Moerdijk T, van Houche J, Timmermans KR (2021a) Effect of salinity and pH on growth, phycoerythrin, and non-volatile umami taste active compound concentration of Rhodomonas salina using a D-optimal design approach. J Appl Phycol 33:3591–3602

Latsos C, Van HJ, Blommaert L, Verbeeke GP, Kromkamp J, Timmermans KR (2021b) Effect of light quality and quantity on productivity and phycoerythrin concentration in the cryptophyte Rhodomonas sp. J Appl Phycol 33:729–741

Lawrenz E, Fedewa EJ, Richardson TL (2011) Extraction protocols for the quantification of phycobilins in aqueous phytoplankton extracts. J Appl Phycol 23:865–871

Ledahudec J, Pokorný J (1991) Effect of free fatty acids on the flavour of frying oil. Food / Nahrung 35:1071–1075

Liang S, Liu X, Chen F, Chen Z (2004) Current microalgal health food R & D activities in China BT-Asian Pacific Phycology in the 21st century: prospects and challenges. In: Ang PO (ed). Kluwer, Dordrecht, pp 45–48

Liu W, Au DWT, Anderson DM, Lam PKS, Wu RSS (2007) Effects of nutrients, salinity, pH and light:dark cycle on the production of reactive oxygen species in the alga Chattonella marina. J Exp Mar Bio Ecol 346:76–86

Liu TT, Xia N, Wang QZ, Chen DW (2019) Identification of the non-volatile taste-active components in crab sauce. Foods 8:324

Lowry OH, Rosenbrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Marcati A, Violeta A, Laroche C, Soanen N, Marchal L, Jubeau S, Djelveh G, Michaud P (2014) Extraction and fractionation of polysaccharides and B-phycoerythrin from the microalga Porphyridium cruentum by membrane technology. Algal Res 5:258–263

Moerdijk-Poortvliet TCW, de Jong DLC, Fremouw R, de Reu S, de Winter JM, Timmermans K, Mol G, Reuter N, Derksen GCH (2022) Extraction and analysis of free amino acids and 5′-nucleotides, the key contributors to the umami taste of seaweed. Food Chem 370:131352

Nishimura T, Kato H (2009) Taste of free amino acids and peptides. Food Rev Int 4:175–194

Norsker NH, Barbosa MJ, Vermuë MH, Wijffels RH (2011) Microalgal production—a close look at the economics. Biotechnol Adv 29:24–27

Ochoa-Alfaro AE, Gaytán-Luna DE, González-Ortega O, Zavala-Arias KG, Paz-Maldonado LMT, Rocha-Uribe A, Soria-Guerra RE (2019) pH effects on the lipid and fatty acids accumulation in Chlamydomonas reinhardtii. Biotechnol Prog 35:1–8

Ogbonda KH, Aminigo RE, Abu GO (2007) Influence of temperature and pH on biomass production and protein biosynthesis in a putative Spirulina sp. Bioresour Technol 98:2207–2211

Oostlander PC, Latsos C, van Houcke J, Wijffels RH, Barbosa MJ (2020a) Production of Rhodomonas sp. at pilot scale under sunlight conditions. Algal Res 48:4–9

Oostlander PC, van Houcke J, Wijffels RH, Barbosa MJ (2020b) Optimization of Rhodomonas sp. under continuous cultivation for industrial applications in aquaculture. Algal Res 47:101889

Paliwal C, Mitra M, Bhayani K, Bharadwaj SVV, Ghosh T, Dubey S, Mishra S (2017) Abiotic stresses as tools for metabolites in microalgae. Bioresour Technol 244:1216–1226

Pettersen AK, Turchini GM, Jahangard S, Ingram BA, Sherman CDH (2010) Effects of different dietary microalgae on survival, growth, settlement and fatty acid composition of blue mussel (Mytilus galloprovincialis) larvae. Aquaculture 309:115–124

Poore J, Nemecek T (2018) Reducing food’s environmental impacts through producers and consumers. Science 360:987–992

Pulz O, Gross W (2004) Valuable products from biotechnology of microalgae. Appl Microbiol Biotechnol 65:635–648

Qiu R, Gao S, Lopez PA, Ogden KL (2017) Effects of pH on cell growth, lipid production and CO2 addition of microalgae Chlorella sorokiniana. Algal Res 28:192–199

Renaud SM, Thinh LV, Parry DL (1999) The gross chemical composition and fatty acid composition of 18 species of tropical Australian microalgae for possible use in mariculture. Aquaculture 170:147–159

Rodríguez C, Pérez JA, Badía P, Izqueierdo M, Fernandez-Palacios H, Hernandez A (1998) The n-3 highly unsaturated fatty acids requirements of gilthead seabream (Sparus aurata L.) larvae when using an appropriate DHA/EPA ratio in the diet. Aquaculture 169:9–23

Rodríguez C, Pérez JA, Díaz M, Izquierdo MS, Fernández-Palacios H, Lorenzo A (1997) Influence of the EPA/DHA ratio in rotifers on gilthead seabream (Sparus aurata) larval development. Aquaculture 150:77–89

Samarakoon K, Jeon YJ (2012) Bio-functionalities of proteins derived from marine algae—a review. Food Res Int 48:948–960

Sathasivam R, Radhakrishnan R, Hashem A, Abd-Allah EF (2019) Microalgae metabolites: a rich source for food and medicine. Saudi J Biol Sci 26:709–722

Seixas P, Coutinho P, Ferreira M, Otero A (2009) Nutritional value of the cryptophyte Rhodomonas lens for Artemia sp. J Exp Mar Bio Ecol 381:1–9

Slade R, Bauen A (2013) Micro-algae cultivation for biofuels: cost, energy balance, environmental impacts and future prospects. Biomass Bioenergy 53:29–38

Soares S, Kohl S, Thalmann S, Mateus N, Meyerhof W, De Freitas V (2013) Different phenolic compounds activate distinct human bitter taste receptors. J Agric Food Chem 61:1525–1533

Sorek M, Yacobi YZ, Roopin M, Berman-Frank I, Levy O (2013) Photosynthetic circadian rhythmicity patterns of Symbiodium, the coral endosymbiotic algae. Proc R Soc B 280:20122942

Sui Y, Vlaeminck SE (2019) Effects of salinity, pH and growth phase on the protein productivity by Dunaliella salina. J Chem Technol Biotechnol 94:1032–1040

Thoisen C, Pedersen JS, Jørgensen L, Kuehn A, Hansen BW, Nielsen SL (2020) The effect of cell density on biomass and fatty acid productivity during cultivation of Rhodomonas salina in a tubular photobioreactor. Aquac Res 51:3367–3375

Thompson PA, Guo M, Harrison PJ (1993) The influence of irradiance on the biochemical composition of three phytoplankton species and their nutritional value for larvae of the Pacific Oyster (Crassostrea gigas). Mar Biol 117:259–268

Torzillo G, Vonshak A (2013) Environmental stress physiology with reference to mass cultures. In: Richmond A, Hu Q (eds) Handbook of microalgal culture. Wiley-Blackwell, Oxford, pp 90–113

United Nations (2017) World population projected to reach 9.8 billion in 2050, and 11.2 billion in 2100 | UN DESA | United Nations Department of Economic and Social Affairs

van Houcke J, Medina I, Maehre HK, Cornet J, Cardinal M, Linssen J, Luten J (2017) The effect of algae diets (Skeletonema costatum and Rhodomonas baltica) on the biochemical composition and sensory characteristics of Pacific cupped oysters (Crassostrea gigas) during land-based refinement. Food Res Int 100:151–160

Verspreet J, Kreps S, Bastiaens L (2020) Evaluation of microbial load, formation of odorous metabolites and lipid stability during wet preservation of Nannochloropsis gaditana concentrates. Appl Sci 10:3419

Yamaguchi K (1996) Recent advances in microalgal bioscience in Japan, with special reference to utilization of biomass and metabolites: a review. J Appl Phycol 8:487–502

Yamaguchi S, Tomoko Y, Shingo I, Tsunehiko N (1971) Measurement of the relative taste intensity of some L-a-amino acids and 5’-nucleotides. J Food Sci 36:846–849

Yamamoto S, Bossier P, Yoshimatsu T (2020) Biochemical characterization of Rhodomonas sp. Hf-1 strain (cryptophyte) under nitrogen starvation. Aquaculture 516:734648

Funding

This work was financially supported by the ValgOrize project, funded by the INTERREG V 2 Seas Mers Zeeën program, with the financial support of the European Regional Development Fund.

Author information

Authors and Affiliations

Contributions

C. Latsos: conceptualization, implementation, investigation, formal analysis, writing original draft, writing — review and editing. J. van Houcke: conceptualization, writing — review and editing, supervision. L. Bastiaens: formal analysis, writing — review and editing. S. van Roy: formal analysis, writing — review and editing. B. Coleman: formal analysis, writing — review and editing. J. Robbens: formal analysis, writing — review and editing, supervision. T. Moerdijk: formal analysis, writing — review and editing. E. Wassenaar: implementation, formal analysis, writing — review and editing. K. R. Timmermans: conceptualization, writing — review and editing, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Latsos, C., Wassenaar, E., Moerdijk, T. et al. Effect of pH on Rhodomonas salina growth, biochemical composition, and taste, produced in semi-large scale under sunlight conditions. J Appl Phycol 34, 1215–1226 (2022). https://doi.org/10.1007/s10811-022-02730-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-022-02730-1