Abstract

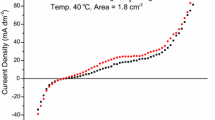

Ni–Nb composite electrocoatings were obtained on carbon steel from Watts bath, containing suspended 20 μm size niobium powders. The effect of cathodic current density, electrolyte stirring rate and concentration of Nb particles in the bath on the deposit morphology and texture, volume fraction of co-deposited Nb particles and microhardness was investigated. The Ni–Nb composite layers presented a rough morphology with randomly oriented Ni grains, whereas pure Ni coatings obtained under the same experimental conditions were smooth and showed highly preferred orientation in the [110] or [100] direction. Stirring rate of the electrolyte and concentration of Nb particles in the bath are the main parameters affecting the incorporation of Nb particles. The Nb incorporated volume fraction was 11–14%, 17–19%, 27–32% and 34–37% for the 20 g L−1 Nb/550 rpm, 20 g L−1 Nb/400 rpm, 40 g L−1 Nb/400 rpm and 40 g L−1 Nb/550 rpm conditions, respectively. The microhardness of the Ni–Nb composite coatings obtained at 20 and 40 mA cm−2 was higher than that of pure Ni layers, due to grain refining. Incorporation of Nb particles in Ni coatings improved the corrosion resistance of the deposits in NaCl and H2SO4 solutions.

Similar content being viewed by others

References

Kim SK, Yoo HJ (1998) Surf Coat Technol 108–109:564

Garcia I, Fransaer J, Celis JP (2001) Surf Coat Technol 148:171

Medeliene V (2002) Surf Coat Technol 154:104

Zimmerman AF, Clark DG, Aust KT, Erb U (2002) Mater Lett 52:85

Hou KH, Ger MD, Wang LM, Ke ST (2002) Wear 253:1003

Socha RP, Laajalehto K, Nowak P (2002) Colloids Surf A 208:267

Wang SC, Wei WCJ (2003) Mater Chem Phys 78:574

Steinbach J, Ferkel H (2001) Script Mater 44:1813

Zhou M, Tacconi NR, Rajeshwar K (1997) J Electroanal Chem 421:111

Abdel Hamid Z, Ghayad IM (2002) Mater Lett 53:238

Berçot P, Peña-Muñoz E, Pagetti J (2002) Surf Coat Technol 157:282

Serek A, Budniok A (2002) Curr Appl Phys 2:193

Panek J, Serek A, Budniok A, Rówinski E, Lagiewka E (2003) Int J Hydrogen Energy 28:169

Susan DF, Barmak K, Marder AR (1997) Thin Solid Films 307:133

He L, Liu H, Chen D, Chen Z, Bai X (2002) Surf Coat Technol 160:109

Lee WH, Tang SC, Chung KC (1999) Surf Coat Technol 120–121:607

Hovestad A, Janssen LJJ (1995) J Appl Electrochem 25:519

ASM Handbook (1993) Corrosion, vol 13. ASM International, Materials Park

ASM Handbook (1994) Surface engineering, vol 5. ASM International, Materials Park

Sandim HRZ (1996) Preparation of Nb-TiO2 alloys by powder metallurgy and its microstructural characterization. PhD Thesis, Universidade de São Paulo

Losiewicz B, Budniok A, Rówinski E, Lagiewka E, Lasia A (2004) J Appl Electrochem 34:507

Selected Powder Diffraction Data-Metals and Alloys-Data Book (1978) JCPDS International Centre for Diffraction Data, Swarthmore

Dini JW (1993) Electrodeposition: the materials science of coatings and substrates. Noyes Publications, Park Ridge

Stroumbouli M, Gyftou P, Pavlatou EA, Spyrellis N (2005) Surf Coat Technol 195:325

Annual Book of ASTM Standards (1992) Volume 02.05, ASTM International

Wang H, Yao S, Matsumara S (2004) J Mater Proc Technol 145:299

Safranek WH (1974) The properties of electrodeposited metals and alloys. Elsevier, New York

Ramesh CS, Seshadri SK (2003) Wear 255:893

Ferkel H, Müller B, Riehemann W (1997) Mater Sci Eng A 234–236:474

Rethinam AJ, Ramesh Bapu GNK, Krishnan RM (2004) Mater Chem Phys 85:251

Garcia I, Conde A, Langelaan G, Fransaer J, Celis JP (2003) Corr Sci 45:1173

Acknowledgements

The authors are grateful to Prof. Dr. H.R.Z. Sandim (EEL-USP) for supplying the niobium powders and R.Q.F. acknowledges CNPq (Conselho Nacional de Desenvolvimento e Pesquisa – Brazil) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Robin, A., Fratari, R.Q. Deposition and characterization of nickel–niobium composite electrocoatings. J Appl Electrochem 37, 805–812 (2007). https://doi.org/10.1007/s10800-007-9315-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-007-9315-3