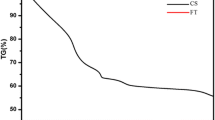

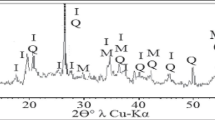

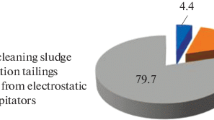

Scientific work on obtaining pigments of different colors from the ‘red sludge’ at the Bogoslovskii Aluminum Plant has been performed. Atechnology for producing red pigments (heat treatment at 290 – 850°C) and black pigments (heat treatment in a controlled atmosphere at temperature 500 – 1000°C) has been developed. Ceramic pigments with the crystal lattice structure of chain pyroxenes and garnets are obtained from red sludge at temperatures 900 – 1100°C. These investigations are aimed at expanding the raw materials base of pigments and reducing their production costs by recycling the wastes.

Similar content being viewed by others

References

I. I. Kalinichenko, V. I. Sokolov, E. A. Nikonenko, et al., “Method for obtaining iron-oxide pigments, RF Patent 2047631,” Byull. Izobr. Polezn. Modeli, No. 31 (1995), published November 10, 1995.

I. Dobrovol’skii, A. Bol’shakov, et al., Methods of Technical Analysis of Pigment Production [in Russian], Yuzhno-Ural’sk Book Publishes, Chelyabinsk (1973).

G. V. Ismagilova, M. P. Kolesnikova, E. A. Nikonenko, et al., “Method of obtaining black iron oxide pigment, RF Patent 2346018,” Byull. Izobr. Polezn. Modeli, No. 4 (2009), published February 10, 2009.

I. V. Pishch and G. N. Maslennikova, Ceramic Pigments [in Russian], Stroimaterialy, Moscow (2009).

S. G. Tumanov, “New ways of synthesizing and classifying ceramic colors,” Steklo Keram., No. 6, 33 – 35 (1967); S. G. Tumanov, “New ways of synthesizing and classifying ceramic colors,” Glass Ceram., 24(6), 330 – 332 (1967).

G. N. Maslennikova, I. V. Pishch, and E. V. Radion, “Current classification of ceramic silicate pigments (Review),” Steklo Keram., No. 9, 5 – 8 (2006); G. N. Maslennikova, I. V. Pishch, and E. V. Radion, “Current classification of ceramic silicate pigments (Review),” Glass Ceram., 63(9 – 10), 281 – 284 (2006).

L. G. Gerasimova and E. S. Shchukina, “Obtaining pigment fillers from aluminosilicates mineral wastes,” Stroit. Mater., No. 6, 69 – 77 (2009).

M. B. Sedel’nikova and V. M. Pogrebenkov, “Production of ceramic pigments with wollastonite and diopside structures using nepheline sludge,” Steklo Keram., No. 10, 28 – 30 (2007); M. B. Sedel’nikova and V. M. Pogrebenkov, “Production of ceramic pigments with wollastonite and diopside structures using nepheline sludge,” Glass Ceram., 64(9 – 10), 363 – 365 (2007).

M. P. Kolesnikova, E. A. Nikonenko, and N. V. Shoppert, “Resource-conserving technology for producing ceramic pigments,” in: Proc. of the 1st Intern. Scientific and Applications Conference: Aspects of Noosphere Safety in Priority Directions of Human Activity [in Russian], Tambov (2010), pp. 44 – 46.

M. P. Kolesnikova, E. A. Nikonenko, and N. V. Shoppert, “Synthesis of pigments from wastes form alumina production,” Ékologiya TsChO RF, No. 2(27), 69 – 70 (2011).

N. V. Shoppert, S. F. Katyshev, E. A. Nikonenko, and M. P. Kolesnikova, “On obtaining pigments from sludge cake at the Bogoslovskii Aluminum Plant,” Nauch.-Tekh. Vestn. Povolzh’ya, No. 1, 292 – 295 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 8, pp. 41 – 44, August, 2015.

Rights and permissions

About this article

Cite this article

Katyshev, S.F., Rukhlyadeva, M.S., Nikonenko, E.A. et al. Obtaining Composite Pigments From Technogenic Wastes From Alumina Production. Glass Ceram 72, 303–305 (2015). https://doi.org/10.1007/s10717-015-9779-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-015-9779-2