Abstract

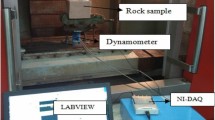

The estimation of strength properties of sedimentary rocks is most often needed during the preliminary phase of many rock engineering projects carrying out in sedimentary regions. The main drawback of determining the rock properties in a test center is the requirement of the number of superior quality rock core specimens. In this experimental investigation, the uniaxial compressive strength (UCS) and tensile strength of sedimentary rocks are estimating using well-identified drilling variables and acoustic parameters obtained during the rotary type rock drilling. The drilling variables such as thrust, torque, and vibration parameters are used to develop the mathematical models of strength properties of rock. A drill type dynamometer was used to measure the drilling variables, and the vibration parameter would measure using the NI-9234 data acquisition system. The prediction efficiency of the mathematical model is evaluating using performance indices. Results show that the used experimental method can estimate the considered responses (UCS and tensile strength) with the acceptable percentage errors of 10.52% and 11.27% respectively, and may be useful to measure the UCS and BTS of sedimentary rocks in a laboratory capacity without test core samples.

Similar content being viewed by others

References

Alam K, Mitrofanov AV, Silberschmidt VV (2011) Experimental investigations of forces and torque in conventional and ultrasonically-assisted drilling of cortical bone. Med Eng Phys 33:234–239

Alber M, Kahraman S (2009) Predicting the uniaxial compressive strength and elastic modulus of a fault breccia from texture coefficient. Rock Mech Rock Eng 42:117–127. https://doi.org/10.1007/s00603-008-0167-x

Aleotti L, Poletto F, Miranda F, Corubolo P, Abramo F, Craglietto A (1999) Seismic while drilling technology: use and analysis of the drill-bit seismic source in a cross-hole survey. Geo-phys Prospect 47:25–39. https://doi.org/10.1046/j.1365-2478.1999.00113.x

Altindag R (2002) The evaluation of rock brittleness concept on rotary blast hole drills. J South Afr Inst Min Metall 102:61–66

Arman H, Khosravi S, Osman MA, Alnaqb FMI, Aishah (2017) Dimension effect on the ultrasonic pulse velocity. Int J Geogr Geol 6(2):18–25

Asanuma H, Niitsuma H (1996) Triaxial seismic measurement while drilling and estimation of subsurface structure. Int J Rock Mech Min Sci Geo Mech Abstr 7(33):307A

Basarir H, Karpuz C (2016) Preliminary estimation of rock mass strength using diamond bit drilling operational parameters. Int J Min Reclam Environ 30(2):145–164

Bhatnagar A, Khandelwal M, Rao KUM (2011) Laboratory investigations for the role of flushing media in diamond drilling of marble. Rock Mech Rock Eng 44:349–356. https://doi.org/10.1007/s00603-011-0144-7

Broch E, Franklin JA (1972) The point-load strength test. Int J Rock Mech Min Sci Geomech Abstr 9(6):669–676

Brook N (1980) Size correction for point load testing. Int J Rock Mech Min Sci Geomech Abstr 17(4):231–235

Brown ET (1981) ISRM rock characterization testing and monitoring suggested methods. Pergamon Press, Oxford

Ceryan N, Okkan U, Kesimal A (2012) Prediction of unconfined compressive strength of carbonate rocks using artificial neural networks. Environ Earth Sci 68(3):807–819. https://doi.org/10.1007/s12665-012-1783-z

Chawre B (2018) Correlations between ultrasonic pulse wave velocities and rock properties of quartz-mica schist. J Rock Mech Geotech Eng 10(3):594–602

Erosy A, Waller MD (1995a) Wear characteristics of PDC pin and hybrid core bits in rock drilling. Wear 188:150–165

Ersoy A, Waller MD (1995b) Prediction of drill-bit performance using multi-variable linear regression analysis. Int J Rock Mech Min Sci Geomech Abstr 6:279A

Fener M (2011) The effect of rock sample dimension on the P-wave velocity. J Non-destr Eval 30:99–105

Finfinger G, Peng S, Gu Q, Thomas WB (2000) An approach to identifying geological properties from roof bolter drilling parameters. In: Proceedings of the 19th international conference on ground control in mining, August 8–10, Morgantown, West Virginia. https://doi.org/10.1080/17480930.2015.1025561

Jamshidi A, Nikudel MR, Khamehchiyan M, Sahamieh RZ (2016) The effect of specimen diameter size on uniaxial compressive strength, P-wave velocity and the correlation between them. Geomech Geo-eng 11(1):13–19

Kabilan N, Muttharam M (2016) Correlation between unconfined compressive strength and indirect tensile strength for jointed rocks. Int J Res Eng Technol 5(5):157–161

Kalantari S, Hashemolhosseini H, Baghbanan A (2018) Estimating rock strength parameters using drilling data. Int J Rock Mech Min Sci 104:45–52. https://doi.org/10.1016/j.ijrmms.2018.02.013

Krishna Raj V, Prabukarthi A, Ramanathan A, Elanghovan N, Kumar MS, Zitoune R, Davim JP (2012) Optimization of machining parameters at high speed drilling of carbon fibre reinforced plastic (CFRP) laminates. Compos B Eng 43(4):1791–1799. https://doi.org/10.1016/j.compositesb.2012.01.007

Kumar BR, Vardhan H, Govindaraj M (2011a) Prediction of uniaxial compressive strength, tensile strength and porosity of sedimentary rocks using sound level produced during rotary drilling. Rock Mech Rock Eng 44(5):613–620. https://doi.org/10.1007/s00603-011-0160-7

Kumar BR, Vardhan H, Govindaraj M (2011b) Prediction of uniaxial compressive strength, tensile strength and porosity of sedimentary rocks using sound level produced during rotary drilling. Rock Mech Rock Eng 4:613–620

Kumar BR, Vardhan H, Govindaraj M, Sowmya PS (2013) Artificial neural network model for prediction of rock properties from sound level produced during drilling. Geomech Geo-eng 8(1):53–61

Li JK, Li FF, Wei XK (2013) The effect of specimen’s height on the point load tests. Adv Mater Res 848:108–111

Liu RH, He R, Li G, Liu Y (2018) Point load test of half-cylinder core using the numerical model and laboratory tests: size suggestion and correlation with cylinder core. Adv Civil Eng. https://doi.org/10.1155/2018/3870583

Miranda F, Aleotti L, Abramo F, Poletto F (1996) Impact of the seismic while drilling technique on exploration wells. First Break 14(2):55–68. https://doi.org/10.3997/1365-2397.1996004

Nazir R, Momeni E, Armaghani DJ, Amin MFM (2013) Correlation between unconfined compressive strength and indirect tensile strength of limestone rock samples. Electron J Geotech Eng 18:1737–1746

Qin M, Wang K, Sun T, Liu Z (2018) Analysis of signal characteristics from rock drilling based on vibration and acoustic sensor approaches. Applied-Acoustics 140:275–282. https://doi.org/10.1016/j.apacoust.2018.06.003

Raghavan V, Murthy CHSN (2018) Prediction of cuttability from rock cutting resistance. The J South Afr Inst Min Metall 118:321–329

Rao KUM, Mishra (1993). Evaluation of field performance of diamond drills. In: Proceedings of the National Symposium, October 15–16, NITK, Surathkal

Rao KUM, Bhatnagar A, Misra B (2002) Laboratory investigations on rotary diamond drilling. Geotech Geol Eng 20:1–16. https://doi.org/10.1023/A:1013864423562

Rostami J, Kahraman S, Naeimipour A, Collins C (2015) Rock characterization while drilling and application of roof bolter drilling data for evaluation of ground conditions. J Rock Mech Geotech Eng 7(3):273–281. https://doi.org/10.1016/j.jrmge.2015.01.006

Roxborough, FF (1987) The role of some basic rock properties in assessing cuttability. In: Proceedings of the seminar on tunnels: wholly engineered structures, Sydney, Australia. The Institute of Engineers Australia and AFCC

Shankar VK, Kunar BM, Murthy CS (2020) Measurement of bit-rock interface temperature and wear rate of the tungsten carbide drill bit during rotary drilling. Friction. https://doi.org/10.1007/s40544-019-0330-2

Sreenivasulu R, Rao CS (2016) Effect of drilling parameters on thrust force and torque during drilling of aluminium 6061 alloy—based on taguchi design of experiments. J Mech Eng 46:41–48. https://doi.org/10.3329/jme.v46i1.32522

Stuart RK., Charles FP, Hans T (2009) Method for borehole measurement of formation properties. US patent issued on October 30

Vardhan H, Adhikari GR, Raj MG (2009) Estimating rock properties using sound levels produced during drilling. Int J Rock Mech Min Sci 46(3):604–612. https://doi.org/10.1016/j.ijrmms.2008.07.011

Vijaya Kumar Ch, Vardhan H, Murthy ChSN (2019a) Estimating rock properties using sound signal dominant frequencies during diamond core drilling operations. J Rock Mech Geotech Eng. https://doi.org/10.1016/j.jrmge.2019.01.001

Vijaya Kumar Ch, Harsha V, Murthy ChSN (2019b) Quantification of rock properties using frequency analysis during diamond core drilling operations. J Inst Eng (India) Ser D 100(1):67–81. https://doi.org/10.1007/s40033-019-00174-5

Vijaya Kumar Ch, Vardhan H, Murthy ChSN (2019c) Multiple regression model for prediction of rock properties using acoustic frequency during core drilling operations. Geomech Geoeng. https://doi.org/10.1080/17486025.2019.1641631

Xu XL, Lu X, Qin ZX, Yang DL (2017) Influence of silica as an abrasive on friction performance of polyimide-matrix composites. Polym Polym Compos 25(1):43–48. https://doi.org/10.1177/096739111702500107

Yari M, Bagherpour R (2018a) Implementing acoustic frequency analysis for development the novel model of determining geomechanical features of igneous rocks using rotary drilling device. Geotech Geol Eng 36(3):1805–1816. https://doi.org/10.1007/s10706-017-0433-3

Yari M, Bagherpour R (2018b) Investigating an innovative model for dimensional sedimentary rocks characterization using acoustic frequencies analysis during drilling. Min Geol Petrol Eng Bull 33(2):17–25

Zborovjan M, Lesso I, Dorcak L (2003) Acoustic identification of rocks during drilling process. J Acta Montan Slov 8(4):91–93

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lakshminarayana, C.R., Tripathi, A.K. & Pal, S.K. Prediction of Mechanical Properties of Sedimentary Type Rocks Using Rotary Drilling Parameters. Geotech Geol Eng 38, 4863–4876 (2020). https://doi.org/10.1007/s10706-020-01332-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-020-01332-3