Abstract

Irrigated cotton in Australia is mainly grown on heavy textured soils which are prone to waterlogging, resulting in significant losses of nitrogen (N) via denitrification and surface run-off. This study investigated fertiliser nitrogen use efficiency (fNUE) over three seasons on five commercial cotton farms using the 15N tracer technique. Fertiliser NUE was consistently low across all fertilised treatments, with on average 47% of the applied fertiliser lost and only 17% of the N taken up by the crop derived from fertiliser. There was no significant effect of different N fertiliser products and rates on cotton lint yield. High lint yields (0.9–3.6 Mg ha−1) could be achieved even without the application of N fertiliser, demonstrating mineralisation of soil organic N, residual fertiliser, or N returned with crop residues, as key source of N in these cropping systems. Using the nitrification inhibitor DMPP and overhead instead of furrow irrigation showed potential to reduce N fertiliser losses. The results demonstrate that under current on-farm management fNUE is low on irrigated cotton farms in Australia and highlight the need to account for soil N stocks and mineralisation rates when assessing optimized fertiliser rates. There is substantial scope to improve fNUE and reduce N losses without any impact on lint yield, by adjusting N fertiliser application rates, in particular in combination with the use of the nitrification inhibitor DMPP. Using overhead instead of furrow irrigation is a promising approach to improve not only water use efficiency, but also fNUE in irrigated cotton systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitrogen (N) fertiliser is a key input for agricultural production and has allowed farmers to greatly increase crop production per unit land over the past century (Foley et al. 2011). To meet the world’s future demand for food, fodder, biofuels and fibre, agricultural production must grow substantially, and if current trends were to continue, global N fertiliser use could double by 2050 (Tilman et al. 2011). Unfortunately, less than 50% of the used fertiliser added to global croplands is currently converted into harvested products and N use efficiency (NUE) has been shown to decline with increasing fertiliser inputs (Lassaletta et al. 2014). This means that, if no action is taken, more and more reactive N (Nr) compounds used for crop production will be lost to the environment causing serious environmental impacts, including eutrophication, biodiversity loss, human health problems and perturbations of the climate system (Galloway et al. 2003; Erisman et al. 2011, 2013). The production of Nr is already exceeding the safe thresholds for human and ecosystem health by over two-fold (Rockström et al. 2009). How to bring global N fertiliser use back within environmental limits while meeting an increasing demand for bio-commodities is arguably one of the most important challenges for humanity in the coming century and requires substantial improvements in NUE of global cropping systems.

In Australia, about 70% of the cotton (Gossypium hirsutum L.) is grown on heavy textured (clay) soils (ICAC 2019). These soils are prone to waterlogging resulting in significant losses of N via denitrification, deep drainage and surface run-off (Macdonald et al. 2017). In irrigated cotton production, N fertiliser is one of the key production drivers with an industry average application rate of 275 kg N ha−1 (range: from less than 100 to 520 kg N ha−1) for irrigated cotton in Australia (Roth Rural 2017). This industry average N rate is higher than the estimated average most economic rate of 234 kg N ha−1 (Antille and Moody 2021; Welsh et al. 2021), clearly demonstrating scope for improving NUE in irrigated cotton systems, by reducing N fertiliser inputs. This is an important management consideration for Australian cotton production systems as N recoveries in crop are low, with only 17–50% of the applied fertiliser N taken-up by the crop, and up to 70% completely lost over the season (Freney et al. 1993; Rochester et al. 1996; Fritschi et al. 2004; Macdonald et al. 2017). Only a few studies have reported NUE in cotton based on 15N fertiliser experiments in Australia, and research has mainly involved the collection of data from experimental research stations, while it is critical to have realistic data from on-farm production systems.

The use of nitrification inhibitors (NI) has been proposed as a strategy to increase NUE and reduce environmental losses of Nr in cropping systems (Abalos et al. 2014). However, recent research suggests that the agronomic efficacy of the NIs needs to be interpreted with caution, since most studies only used one N rate while potential benefits of NIs might be best achieved by downward adjusting N application from the conventional rate (Li et al. 2018; Rose et al. 2018). Moreover, current research on NIs has focused on cereal systems (De Antoni Migliorati et al. 2014; Alonso-Ayuso et al. 2016; Lester et al. 2016; Liu et al. 2019), with only a limited number of recent studies conducted in cotton (Bronson et al. 2017; Schwenke and McPherson 2018). Early research on NIs in cotton suggested that NUE could be markedly improved by the use of NIs (Freney et al. 1993; Rochester et al. 1996), but latest studies using novel NI formulations failed to show a significant effect on cotton yield, lint quality or NUE (Watts et al. 2014; Li et al. 2020).

In Australia, approximately 90% of the cotton-growing area is irrigated, and 92% of this irrigated area relies on gravity surface-irrigation systems, the majority of which are furrow irrigation systems (Roth Rural 2017; ICAC 2019; Roth et al. 2013). Recurrent droughts, water availability challenges, and less reliable rainfall have increased growers’ interest in overhead and drip irrigation systems. Consequently, adoption of these systems has increased, but still represents only a small proportion (≤ 10% of the total irrigated cotton area) of the Australian industry (ICAC 2019). Some of the reported advantages of overhead and drip irrigation systems compared with furrow irrigation systems are water savings of up to 20–30%, reduced risk of waterlogging, ability to apply fertilisers in-crop (fertigation) more efficiently, and reduced risk of nutrient and sediment losses (McHugh et al. 2008; Foley et al. 2013). However, little research has been conducted on how different irrigation systems affect NUE in cotton production. In Australia, Antille (2018) found significantly lower N2O emissions, and in the USA, Bronson et al. (2017) reported greater fertiliser N recoveries in overhead compared to surface irrigation systems, but studies on the effect of irrigation system on fertiliser NUE using 15N tracers are still lacking for irrigated cotton. The objectives of this study were to (i) assess crop N uptake and fertiliser N use efficiency (fNUE) on commercial cotton farms in Australia, and (ii) investigate the effect of fertiliser management (N source and rate) and irrigation system on fNUE on these farms.

Material and methods

Study site

Over three years (2015–2018) field trials were undertaken at five different commercial farms located in the Eastern Darling Downs region about 150 km west of Brisbane, Australia (27.53° S, 150.58° E). The region is noted for its deep fertile clay soils, making it one of the most productive in Australia for grain and cotton production. The soils at the different experimental sites are classified as Black Vertosols (Isbell 2021), or Vertisols (USDA-NRCS 1999), and have clay contents between 45 and 72% in the top 1 m of the profile. The region has a sub-tropical climate (classified as Cfa, according to Köppen climate classification) with warm to hot, moist summers and mild to cool, fairly dry winters. Summer average maximum temperatures range from 28 to 34 °C, while the winter average maximum ranges from 13 to 19 °C. Mean annual precipitation ranges from 600 to 700 mm (Commonwealth Bureau of Meteorology) with about 70% of the total annual rainfall falling between October and March, during the summer crop growing season.

Experimental design

Field trials at all sites used a randomized complete block design with four replicates. The main plots (macro-plots) measured 3 m (width) × 6 m (length) and to avoid edge effects each macro-plot was separated from the others by a buffer of 1 m along the width and length. All sites were irrigated for each of the three cropping seasons. Each year, the trials were conducted on two furrow irrigated, and one overhead irrigated fields (Table 1). The plant inter-row space was either 1-m (40 inches) or 1.5-m (60 inches) depending on the site with a plant density of typically 10–14 plants m−1. The trials followed standard farm practice in terms of fertiliser management, land preparation and general crop husbandry, which relied on local agronomic advice. Crop residues were retained on the field after harvest and subsequently incorporated during land preparation before the following crop was established. Shallow (< 150 mm deep) and deeper (≈ 250 mm deep) incorporation of crop residues are standard practices under overhead and furrow irrigation systems, respectively. At the five commercial farms, the farmer’s N practice was compared with up to two potential N best management practices (namely: reduced fertiliser rate, and nitrification inhibitor). Table 1 shows the different fertiliser rates used and treatments investigated at the commercial farms over the three years.

The fertiliser treatments were:

-

i.

ZERO N: no added N fertiliser.

-

ii.

UREA-FP: urea fertiliser application following the standard farmer practice at each farm.

-

iii.

UREA-red: urea fertiliser application following the standard farmer practice at a 30% reduced N rate.

-

iv.

DMPP-red: urea fertiliser coated with the NI 3,4-dimethyl-pyrazole phosphate (DMPP), following the standard farmer practice at a 30% reduced N rate.

15N recovery plots

To assess the recovery of N fertiliser in the soil and plant, 15N-labelled fertiliser was used in 1 m (width) × 2 m (length) subplots (or micro-plots) located within the unfertilised macro-plots (3 m × 6 m). At all sites, 15N-labelled fertiliser was applied at planting by distributing 10% atom excess 15N enriched urea dissolved in 1 L of deionised water. Depending on the local farmer’s practice, 15N labelled fertilisers were applied within the subplots with a dispenser over the entire micro-plot area (to mimic broadcasting) or 100 mm from each side of the crop row to mimic. In the DMPP-red treatments, the solution containing 15N-enriched urea also included DMPP at a ratio of 6 g DMPP kg−1 urea to replicate the same ratio of commercial DMPP urea (Incitec Pivot Fertilisers, personal communication).

15N plots soil sampling and analysis

To assess the fate of the applied 15N fertiliser all micro-plots were sampled destructively at harvest. Following plant harvest, the entire upper soil layer 0–200 mm was removed from the centre of the micro-plot (width: 0.5 m, length 2 m) and mixed together. In addition, soil samples were collected at three lower depth intervals (200–400, 400–700, 700–1000 mm) with a hydraulic core sampler (50 mm diameter) across a four core transect. The transect was perpendicular to the plant row and extended 500 mm on each side of the crop row. At the furrow irrigation sites, two cores per transect were placed over the fertilised bed and two in the unfertilised furrow. At the overhead irrigated sites, two cores per transect were placed over the fertiliser band and two in the unfertilised inter-row. For each plot, the soil samples belonging to the same depth and section of the transect (bed, furrow, fertiliser band and inter-row) were mixed together before being subsampled. A sub-sample was oven-dried at 60 °C and ground using a planetary cylinder mill. 15N enrichment was determined using an isotope ratio mass spectrometer (20–22 IRMS, Sercon Ltd, Crewe, UK).

Plant sampling and analysis

Aboveground biomass and total N uptake were determined at harvest from representative samples collected in all macro-plots by cutting 1-m of crop row near the soil surface using hand clippers. Both aboveground and belowground material was collected in the 15N micro-plots. Plant samples were oven-dried for 24 h at 60 °C after separating the lint and seed from the rest of the aboveground plant material. The different components of plant biomass (lint, seeds, stems + leaves + ball walls, main and secondary roots) were then weighed, ground in a planetary cylinder mill, and analysed separately. Plant samples were analysed for 15N enrichment using the same isotope ratio mass spectrometer as for the soil analysis (20–22 IRMS, Sercon Ltd, Crewe, UK).

Ancillary measurements

In addition to the 15N analysis, soil samples collected at planting and harvest at four depths (0–200, 200–400, 400–700, 700–1000 mm) were analysed for dry bulk density and mineral N. Nitrate (NO3−) and ammonium (NH4+) were extracted from the soil samples by adding 80 mL of 2 M KCl to 20 g of field-moist soil and shaking it for 1 h. Concentrations of NO3− and NH4+ in the extracts were measured calorimetrically using a discrete analyser (SEAL AQ2 + , SEAL Analytical Inc., USA).

Calculations and statistical analysis

All 15N fertiliser recovery calculations were conducted on an oven-dried basis. Total recovery of applied 15N-labelled fertiliser was determined by mass balance. The percentage of N derived from the labelled fertiliser (Ndff) in each plant and soil pool was determined using Eqs. 1 and 2 (IAEA 2001):

The internal crop N-use efficiency (iNUE) was determined by dividing lint yield by crop N uptake (kg lint kg−1 crop N uptake) (Rochester 2011).

Mixed-effect models were used to analyse the effects of fertiliser type on each of the target variables, namely: lint yield, iNUE, plant N uptake, N recovery rates in plant material and N in soil, as well as N loss rates (Tables 2 and 3). Besides the fixed effect for the fertiliser type, a random effect for the interaction of site-year was introduced in order to control for specific effects of site and year. To correct for the multiple testing problem, the Bonferroni–Holm method was used to adjust the rejection criteria for each of the hypotheses.

Statistical analyses were performed with the R software (version 3.5.3) (R Core Team 2019) using the packages lme4 (version 1.1–21) (Bates et al. 2015), multcomp (version 1.4–12) (Hothorn et al. 2008), and lmerTest (version 3.1) (Kuznetsova et al. 2017).

Results

Lint yield, total biomass and crop N uptake

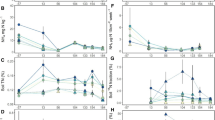

The average cotton lint yield across UREA-FP treatments was 2.4 ± 0.2 Mg ha−1, with an average N application rate of 161 kg N ha−1 (Table 2). Lint yields in fertilised treatments varied significantly between-seasons and were highest (2.7 ± 0.1 Mg ha−1) in the 2015/2016 season and lowest (1.9 ± 0.2 Mg ha−1) in the 2017/2018 season (Table 1). The reduced N fertiliser treatments were not significantly different in lint yields compared to UREA-FP, but there was a positive response in yield to N fertiliser (p < 0.05). Application of N fertiliser (UREA-FP and UREA-red) increased cotton yields by 20% compared to the ZERO N (Table 2). Total aboveground biomass ranged from 9.6 to 19.6 (average 13.1 Mg ha−1) across the different sites and years. On average, the total aboveground biomass contained 60% leaves and stem material, 20% seed and 20% lint. Total crop N uptake ranged from 63 to 424 kg N ha−1 in all fertilised treatments and increased significantly with increasing yield (Fig. 1). The average N uptake in the UREA-FP treatment was 225 (± 20) kg N ha−1.

Relationship between lint yield and crop N uptake with multiple N fertiliser products for all experimental sites across three consecutive cropping seasons (2015/2016, 2016/2017 and 2017/2018). Trendlines are least square linear regressions with the intercept set to zero for each season. Slope of the trendlines shows the average iNUE (lint yield divided by plant N uptake)

Reducing the N fertiliser application rate and the use of the NI had no effect on total N uptake in comparison to UREA-FP, but N uptake was significantly lower (average of 194 kg N ha−1) in the ZERO N plots. Application of N fertiliser increased N uptake compared to the ZERO N treatment by 36, 31, and 33 kg N ha−1 in the DMPP-red, UREA-red, and UREA-FP treatment, respectively.

Average internal crop N-use efficiency (iNUE) across all years and treatments was 10.9 kg lint kg−1 crop N uptake, with no significant effect of N fertiliser treatment (Table 2) and was significantly higher in the 2015/2016 season (13.19 kg lint kg−1 crop N uptake) compared to 2016/2017 and 2017/2018 with 8.69 kg lint kg−1 crop N uptake and 9.45 kg lint kg−1 crop N uptake, respectively (Fig. 1).

15N fertiliser recovery and losses

On average, only 25% (range 11–53%) of the applied 15N fertiliser was taken up by the crop across all fertilised treatments (Fig. 2). The use of DMPP significantly increased fertiliser N recovery in the plant (32 ± 4% of the applied N fertiliser), compared to the FP (25 ± 3%) and UREA-red treatment (26 ± 3%) (Table 3). These relative recovery rates translate to an absolute amount of fertiliser taken up by the plant of 39.0 (± 3.7) kg N ha−1 in the FP treatment, with similar uptake in the DMPP-red treatment, and a significantly reduced uptake in the UREA-red treatment. An average 28 (± 4%) of the N fertiliser remained in the soil profile at harvest (range 8–57%) with no significant effect of the N management (30% reduced N rate, DMPP). Absolute amounts of fertiliser N found in soils amounted to 42.5 (± 4.0) kg N ha−1 in the UREA-FP and were significantly lower in the DMPP-red (by 9.3 ± 4.1 kg N ha−1) and UREA-red (by 14.5 ± 4.0 kg N ha−1) treatment, respectively.

Across all experimental sites and treatments, 47% (± 5%) of the applied N fertiliser was completely lost from the soil–plant system during the season, with losses ranging from 9 to 88% (Fig. 2). Fertiliser N losses were significantly lower (38%) in the DMPP-red compared to the UREA-red (49%) treatment (Table 3). Overall N fertiliser losses were lower in the overhead irrigated sites (35%) compared to the furrow irrigated sites (51%), but this effect was not statistically significant due to the higher N rates used in the furrow irrigated systems. Only 17% (35 kg N ha−1) of the N taken up by the crop was derived from fertiliser (Ndff) and the remaining 83% (182 kg N ha−1) was supplied by the soil. UREA-red reduced Ndff compared to UREA-FP by 28%, but Ndff was not significantly different when DMPP fertiliser was used with the reduced rate (DMPP-red) (Table 3).

Discussion

Cotton yields on commercial farms in Australia

The average lint yield in Australia is approximately three times higher than the world average (Redfern 2021). Bronson et al. (2017) reported lint yields ranging from 1.6 to 2.1 Mg ha−1 for surface and overhead sprinkler irrigated cotton in Arizona, USA, while lint yields for cotton grown under drip-fertigation in arid NW China measured by Li et al. (2020) averaged 1.0 Mg ha−1. The average lint yield found in our study agree well with the average lint yield of 2.6 Mg ha−1 reported for irrigated cotton in Australia (ICAC 2019), and are in line with recent studies from Australia that reported lint yields ranging from 1.9 to 3.2 Mg ha−1 (Rochester et al. 2016). In Australia, lint yields have increased significantly over the past twenty years, from 1.6 Mg ha−1 in 2003–2004 to 2.6 Mg ha−1 in 2014–2015 (Baird 2016). Most of this yield gain is explained by plant-breeding advances, adoption of high-yielding transgenic cotton cultivars (e.g., SICOT 746B3F and SICOT 748B3F), and improved management practices such as increased use of irrigation scheduling technologies and optimization of furrow-irrigated systems (Braunack 2013; Liu et al. 2013; Roth Rural 2017).

N uptake and the internal crop N-use efficiency

The use of high-yielding cultivars also requires a high N uptake. While lint yield has increased by ~ 40% over the past 20 years, the crop N uptake required to support these high yield has increased by ~ 140% (Rochester et al. 2016). Consequently, the average N uptake of the cotton plant in our study increased significantly with increasing yield (Fig. 1), and the internal crop N-use efficiency (iNUE; i.e. kg lint kg−1 crop N uptake) declined with increased crop N uptake. However, there was no clear correlation between yield and iNUE as shown by Rochester et al. (2016) and no clear effect of N treatment demonstrating that, at the commercial cotton farms, other factors than N supply constrained yields. Internal crop N-use efficiency was significantly higher in the 2015/2016 season (13.2 kg lint kg−1) with the highest lint yields, compared to 2016/2017 (8.7 kg lint kg−1) and 2017/2018 (9.4 kg lint kg−1), where yields were significantly lower (Fig. 1). The difference between the years can mainly be attributed to the climatic conditions in the different years and a higher overall yield potential in 2015/2016 (and relatively high soil moisture in the profile going into winter) compared to 2016/2017 and 2017/2018. The average iNUE across all years and treatments of 10.9 kg lint kg−1 crop N uptake was lower than the optimum iNUE value of 11.5–13.5 kg kg lint kg−1 crop N uptake as defined by Rochester (2011) and Bronson (2021). This suggested that soil N supply during the growing season was relatively high (in particular in 2016/2017 and 2017/2018), which therefore affected N use efficiency and resulted in elevated losses of N to the environment.

Fertiliser N use efficiency and losses

The 15N fertiliser experiments clearly showed that the majority of N taken up by the cotton crop at all commercial farms was derived from the soil. On average, only 17% of the N taken up by the crop was derived from fertiliser i.e. 83% was soil derived N. This is at the lower end of Ndff values (23–52%) typically reported for irrigated cotton systems (Fritschi et al. 2004; Macdonald et al. 2017; Rochester et al. 1996), and demonstrates that the availability of fertiliser N which is typically applied before planting is not synchronised with N demands of the cotton plant which is highest during boll development (50 to 100 days after planting). At this stage most of the fertiliser N has been lost or immobilised and mineralisation of soil organic N, containing residual N from previous fertilisation events, or N returned with crop residues becomes the main source of N for the cotton plant.

Only 25% of the applied N fertiliser was directly taken up by the crop compared to 47% of the N fertiliser being lost during each cropping season. The amounts of 15N fertiliser lost are substantially higher than those reported for irrigated cotton systems in the US, where 88–100% of the applied fertiliser was recovered in plants and soil at the end of the season (Bronson et al. 2019; Fritschi et al. 2004), but are consistent with 15N recovery studies in Australia where fertiliser losses of 30–60% have been reported (Freney et al. 1993; Rochester et al. 1996).

The significant differences in N loss rate are attributable to a combination of factors, including irrigation method, N fertiliser rate, fertiliser product, and soil type. Bronson et al. (2019) found little or no significant N losses in a sub-soil drip irrigation system with a high frequency of N fertigation, showing that joint optimisation of water and N supply via fertiliser can reduce N losses and improve NUE. High N losses recorded in our study confirmed the fact that fNUE in irrigated cotton production on heavy textured soils in Australia is low under current on-farm management strategies and that large losses of N to the atmosphere or via deep drainage and surface water runoff pathways can be expected (Ringrose-Voase and Nadelko 2014; Rochester 2003). This finding is also supported by a recent study from Australia that found total N losses of 153 kg N ha−1 from irrigated cotton over one season, resulting in a soil N budget deficit of 42 kg N ha−1, despite an optimised N split fertiliser application of 232 kg N ha−1 (Macdonald et al. 2017). Whilst a full N budget could not be constructed from our data, it appeared that more soil N was removed from the N fertilized treatments at harvest with lint and seed (76 kg N ha−1) than fertiliser N was recovered in soil or returned with the cotton residues at harvest (38 kg N ha−1 and 19 kg N ha−1, respectively), indicating a negative soil N budget. Such a deficit would have implications for the long-term productivity and sustainability of these systems. However, we still lack reliable data on in-season gross mineralisation rates and the amount of N lost from native soil (non-fertiliser) N from irrigated cotton systems, severely constraining our understanding of a complete N budget.

Effect of fertiliser management and irrigation system on fNUE and N losses

The different N management strategies tested (30% reduced rate and NI DMPP) had no significant effect on lint yield, total biomass or N uptake, and produced high cotton yields comparable to the UREA-FP treatments. If analysed on a per-site year analysis, only one site (Yargullen OH 2015/2016) showed a significant effect of N fertilisation on yield while all other trials produced high cotton yields, comparable to the fertilised treatments, without the application of N fertiliser. At only one trial (Yargullen OH 2015/2016) yields were significantly lower under the reduced N fertilisation compared to the farmers practice (Table 1). This is in direct contrast to previous N fertiliser trials on experimental research stations, where typically a positive response in cotton lint yield to applied N fertiliser is reported (Rochester et al. 2016). This demonstrates that the commercial farms investigated in this project already had high levels of available N in the soil, most likely due to excessive N fertiliser applications in previous years, providing substantial scope to reduce N fertiliser rates without any negative impact on lint yield.

Due to the lack of clear fertiliser responses, there was also no significant effect of DMPP on yield or N uptake in these treatments, but the 15N recovery study revealed that DMPP has the potential to increase NUE in irrigated cotton systems. Compared to conventional urea, DMPP increased fertiliser plant recovery by 20% and reduced N fertiliser losses by 30%. This is consistent with earlier 15N studies on inhibitors in cotton that showed that NI inhibitors can markedly increase NUE in irrigated cotton (Freney et al. 1993; Rochester et al. 1996), but in contrast to recent studies in cotton and meta-analyses that reported no or only marginal effects of NIs on yield and NUE when assessed against conventional N fertilisers (Li et al. 2020; Watts et al. 2014; Abalos et al. 2014). However, it is known that NIs are unlikely to increase yields beyond conventional N fertilisers when the control fertiliser treatment is applied at the recommended rate for achieving maximum N-limited yield, while the potential benefits of NIs might be best achieved by downward adjusting N application from the conventional rate (Li et al. 2018; Rose et al. 2018). The high levels of available soil N at all sites, most likely due to excessive N fertiliser applications in previous years, would, therefore, have masked any effect of the NI. Long term trails on the effect of DMPP in irrigated cotton systems are required to better assess the overall potential of this product to increase NUE and yield. Ideally, these are undertaken with reduced N rates over multiple years and also quantify the residual effect of applied N fertiliser on N availability for subsequent crops (Yan et al. 2014).

The percentage of N fertiliser lost tended to be lower in the overhead irrigated sites (35%) compared to the furrow irrigated sites (51%). However, this effect was not significant since N fertiliser rates were higher at the furrow irrigated sites, which may have biased the results. Moreover, lateral fertiliser movement from the micro-plot to other parts of the field may have been greater in the furrow irrigated sites, which makes a direct comparison difficult. Higher N losses from furrow irrigation may be caused by prolonged saturation and waterlogging during and after irrigation events, resulting in increased denitrification losses. For example, a study by Antille (2018) at the Yargullen site showed that soil emissions of N2O over a 30-day period following application of N via fertigation were approximately eight times higher in furrow compared with overhead irrigation. Such results were attributed to differences in water-filled pore space (WFPS) and the extent of soil moisture drawdown observed within five days after fertigation was applied. Concurrent with our study, Antille (2018) further reported that wetter soil conditions persisted for longer in the furrows system compared with the overhead system in which WFPS decreased to less than 45% within five days of irrigation. In most soils, N2O emissions increase significantly when the WFPS is > 60%(Li et al. 2005), while above 80% WFPS, the N2/(N2 + N2O) product ratio increases resulting in higher N2 losses from denitrification due to complete denitrification (Friedl et al. 2016). Clearly, more direct comparisons are needed to better understand the underlying mechanisms. But our observations are consistent with US data on irrigated cotton that report reduced N losses with overhead sprinklers compared to surface irrigation (Bronson et al. 2017), indicating that the increased use of overhead irrigation systems at commercial cotton farms in Australia might not only increase water use efficiency but also has beneficial effects on crop NUE.

Summary and conclusions

The study presents the most comprehensive dataset on 15N recovery trials in irrigated cotton on commercial farms in Australia. Over 3 years, 24 cotton production system treatments were analysed using 15N fertilisers at five different commercial farms. Fertiliser NUE in irrigated cotton production on heavy textured (clay) soils in South Queensland, Australia was low under current management strategies, with almost half of the applied fertiliser lost over the season and only 17% of the N taken up by the crop derived from fertiliser. There was no significant effect of different N fertiliser products and cotton (lint) yield was not affected when N application rate was reduced by 30%. High yields could be achieved even without the application of N fertiliser. This shows that commercial farms have highly elevated levels of available N in the soil at sowing, most likely due to excessive N fertiliser applications in previous years and rely on mineralisation of soil organic N and residual fertiliser as the primary N source. It is noteworthy that the average N application rate in our study (137 kg N ha−1) that focussed on cotton farms in South East Queensland was half the industry average application rate (i.e., 275 kg N ha−1) for irrigated cotton in Australia. This indicates that average N losses across the industry might be significantly higher than the values reported in this study.

We conclude that there is scope to reduce N fertiliser rates in irrigated cotton production systems on commercial holdings in Australia, and this could be done without compromising productivity. However, the residual effect of N fertiliser applied in previous years needs to be considered when assessing optimised fertiliser rates. Despite the high N inputs at the commercial farms, more native soil N was removed with the harvest than fertiliser N was recovered in the soil or returned with the crop residues, indicating an overall N budget deficit that could lead to long term, unsustainable declines of soil organic matter (SOM) on the farms. Considering the high N application rates this potential mining of soil N might appear contradictory, but indicates that high fertiliser application rates alone do not prevent mining of soil nitrogen. It is more important to better synchronise crop N demand with N supply from all sources including soil and fertiliser N and establish management strategies that sustain or build SOM stocks.

The use of the NI DMPP confirmed its potential to increase NUE in irrigated cotton systems, in particular in combination with reduced rates. Moreover, the increasing use of the centre-pivot and lateral-move irrigation systems (compared to furrow irrigation) is a promising approach to improving both water use efficiency and NUE. Longer term studies are required to optimise management strategies that reduce N losses and improve fertiliser and water use efficiency to ensure the Australian cotton industry achieves its vision of being a global leader in sustainable cotton production.

References

Abalos D, Jeffery S, Sanz-Cobena A, Guardia G, Vallejo A (2014) Meta-analysis of the effect of urease and nitrification inhibitors on crop productivity and nitrogen use efficiency. Agric Ecosyst Environ 189:136–144

Alonso-Ayuso M, Gabriel JL, Quemada M (2016) Nitrogen use efficiency and residual effect of fertilizers with nitrification inhibitors. Eur J Agron 80:1–8

Antille DL (2018) Evaluation of fertigation applied to furrow and overhead irrigated cotton grown in a Black Vertosol in Southern Queensland, Australia. Appl Eng Agric 34:197–211

Antille DL, Moody PW (2021) Nitrogen use efficiency indicators for the Australian cotton, grains, sugar, dairy and horticulture industries. Environ Sustain Indic 10, Article number 100099

Baird J (2016) Optimising nitrogen application in a cotton farming system. In: Proceedings of the 7th international nitrogen initiative conference (INI 2016) "Solutions to improve nitrogen use efficiency for the world". Melbourne, VIC, Australia, 4–8 Dec 2016: International Nitrogen Initiative. https://www.ini2016.com/conference-proceedings-2/

Bates D, Mächler M, Bolker B, Walker S (2015) Fitting linear mixed-effects models using lme4. J Stat Softw 67:1–48

Braunack M (2013) Cotton farming systems in Australia: factors contributing to changed yield and fibre quality. Crop Pasture Sci 64:834–844

Bronson KF, Hunsaker DJ, Mon J, Andrade-Sanchez P, White JW, Conley MM, Thorp KR, Bautista E, Barnes EM (2017) Improving nitrogen fertilizer use efficiency in surface- and overhead sprinkler-irrigated cotton in the desert southwest. Soil Sci Soc Am J 81:1401–1412

Bronson KF, Hunsaker DJ, Meisinger JJ, Rockholt SM, Thorp KR, Conley MM, Williams CF, Norton ER, Barnes EM (2019) Improving nitrogen fertilizer use efficiency in subsurface drip-irrigated cotton in the desert southwest. Soil Sci Soc Am J 83:1712–1721

De Antoni MM, Bell MJ, Grace PR, Rowlings DW, Scheer C, Strazzabosco A (2014) Assessing agronomic and environmental implications of different N fertilisation strategies in subtropical grain cropping systems on Oxisols. Nutr Cycl Agroecosyst 100:369–382

Erisman JW, Galloway J, Seitzinger S, Bleeker A, Butterbach-Bahl K (2011) Reactive nitrogen in the environment and its effect on climate change. Curr Opin Environ Sustain 3:281–290

Erisman JW, Galloway JN, Seitzinger S, Bleeker A, Dise NB, Petrescu AMR, Leach AM, de Vries W (2013) Consequences of human modification of the global nitrogen cycle. Philos Trans R Soc B Biol Sci 368(1621):1–9

Foley JA, Ramankutty N, Brauman KA, Cassidy ES, Gerber JS, Johnston M, Mueller ND, O’Connell C, Ray DK, West PC, Balzer C, Bennett EM, Carpenter SR, Hill J, Monfreda C, Polasky S, Rockström J, Sheehan J, Siebert S, Tilman D, Zaks DPM (2011) Solutions for a cultivated planet. Nature 478:337–342

Foley J, Smith P, Wiggington D (2013) Centre pivot and lateral move systems. In: Wiggington D (ed) WATERpak: a guide for irrigation management in cotton and grain farming systems. Cotton Research and Development Corporation (Australian Government), Narrabri, NSW, Australia, pp 392–425

Freney JR, Chen DL, Mosier AR, Rochester IJ, Constable GA, Chalk PM (1993) Use of nitrification inhibitors to increase fertilizer nitrogen recovery and lint yield in irrigated cotton. Fertil Res 34:37–44

Friedl J, Scheer C, Rowlings DW, McIntosh HV, Strazzabosco A, Warner DI, Grace PR (2016) Denitrification losses from an intensively managed sub-tropical pasture—impact of soil moisture on the partitioning of N2 and N2O emissions. Soil Biol Biochem 92:58–66

Fritschi FB, Roberts BA, Rains DW, Travis RL, Hutmacher RB (2004) Fate of nitrogen-15 applied to irrigated acala and pima cotton. Agron J 96(3):646–655

Galloway JN, Aber JD, Erisman JW, Seitzinger SP, Howarth RW, Cowling EB, Cosby BJ (2003) The nitrogen cascade. Bioscience 53:341–356

Hothorn T, Bretz F, Westfall P (2008) Simultaneous inference in general parametric models. Biom J 50:346–363

IAEA (2001) Use of isotope and radiation methods in soil and water management and crop nutrition. Manual (No. IAEA-TCS-14). Joint FAO/IAEA Division of Nuclear Techniques in Food and Agriculture

ICAC (2019) Cotton data book 2020: a report by the technical information section of the international cotton advisory committee. ICAC®, Washington DC, USA, p 534

Isbell RF (2021) The Australian soil classification. CSIRO Publishing, Melbourne

Kuznetsova A, Brockhoff PB, Christensen RHB (2017) lmerTest package: tests in linear mixed effects models. J Stat Softw 82:1–26

Lassaletta L, Billen G, Grizzetti B, Anglade J, Garnier J (2014) 50 year trends in nitrogen use efficiency of world cropping systems: the relationship between yield and nitrogen input to cropland. Environ Res Lett 9, Article number 105011

Lester DW, Bell MJ, Bell KL, De Antoni MM, Scheer C, Rowlings D, Grace PR (2016) Agronomic responses of grain sorghum to DMPP-treated urea on contrasting soil types in North-Eastern Australia. Soil Res 54:565–571

Li Y, Chen D, Zhang Y, Edis R, Ding H (2005) Comparison of three modeling approaches for simulating denitrification and nitrous oxide emissions from loam-textured arable soils. Global Biogeochem Cycles 19(3):1–15

Li T, Zhang W, Yin J, Chadwick D, Norse D, Lu Y, Liu X, Chen X, Zhang F, Powlson D, Dou Z (2018) Enhanced-efficiency fertilizers are not a panacea for resolving the nitrogen problem. Global Change Biol 24(2):e511–e521

Li Y, Hu M, Tenuta M, Ma Z, Gui D, Li X, Zeng F, Gao X (2020) Agronomic evaluation of polymer-coated urea and urease and nitrification inhibitors for cotton production under drip-fertigation in a dry climate. Sci Rep 10, Article number: 1472

Liu S, Constable G, Reid P, Stiller W, Cullis B (2013) The interaction between breeding and crop management in improved cotton yield. Field Crop Res 148:49–60

Liu S, Wang X, Yin X, Savoy HJ, McClure A, Essington ME (2019) Ammonia volatilization loss and corn nitrogen nutrition and productivity with efficiency enhanced uan and urea under no-tillage. Sci Rep 9, Article number: 6610

Macdonald BCT, Chang YF, Nadelko A, Tuomi S, Glover M (2017) Tracking fertiliser and soil nitrogen in irrigated cotton: uptake, losses and the soil N stock. Soil Res 55:264–272

McHugh AD, Bhattarai S, Lotz G, Midmore DJ (2008) Effects of subsurface drip irrigation rates and furrow irrigation for cotton grown on a vertisol on off-site movement of sediments, nutrients and pesticides. Agron Sustain Dev 28:507–519

R Core Team (2019) A language and environment for statistical computing. Vienna, Austria: R Foundation for Statistical Computing. R Foundation for Statistical Computing, Vienna

Redfern R (2021) The Australian cotton industry. In: CRDC and CottonInfo (eds) 2021 Australian Cotton Production Manual. Narrabri, NSW, Australia: Cotton Research and Development Corporation (Australian Government), pp 4–6. https://www.cottoninfo.com.au/publications/australian-cotton-production-manual

Ringrose-Voase AJ, Nadelko AJ (2014) Deep drainage in a Grey Vertosol under furrow-irrigated cotton. Crop Pasture Sci 64:1155–1170

Rochester IJ (2003) Estimating nitrous oxide emissions from flood-irrigated alkaline grey clays. Aust J Soil Res 41:197–206

Rochester IJ (2011) Assessing internal crop nitrogen use efficiency in high-yielding irrigated cotton. Nutr Cycl Agroecosyst 90:147–156

Rochester IJ, Bange M (2016) Nitrogen fertiliser requirements of high-yielding irrigated transgenic cotton. Crop Pasture Sci 67:641–648

Rochester I, Constable G, Saffigna P (1996) Effective nitrification inhibitors may improve fertilizer recovery in irrigated cotton. Biol Fertil Soils 23:1–6

Rockström J, Steffen W, Noone K, Persson Å, Chapin Iii FS, Lambin EF, Lenton TM, Scheffer M, Folke C, Schellnhuber HJ, Nykvist B, de Wit CA, Hughes T, van der Leeuw S, Rodhe H, Sörlin S, Snyder PK, Costanza R, Svedin U, Falkenmark M, Karlberg L, Corell RW, Fabry VJ, Hansen J, Walker B, Liverman D, Richardson K, Crutzen P, Foley JA (2009) A safe operating space for humanity. Nature 461:472–475

Rose TJ, Wood RH, Rose MT, Van Zwieten L (2018) A re-evaluation of the agronomic effectiveness of the nitrification inhibitors DCD and DMPP and the urease inhibitor NBPT. Agric Ecosyst Environ 252:69–73

Roth G, Harris G, Gillies M, Montgomery J, Wigginton D (2013) Water-use efficiency and productivity trends in Australian irrigated cotton: a review. Crop Pasture Sci 64:1033–1048

Roth Rural (2017) Cotton Growing Practices 2016: Findings of the CRDC's survey of cotton growers. Narrabri, NSW, Australia: Cotton Research and Development Corporation (Australian Government). http://www.insidecotton.com/xmlui/handle/1/4429

Schwenke G, McPherson A (2018) Mitigation of nitrous oxide emissions from furrow-irrigated Vertosols by 3, 4-dimethyl pyrazole tetra-methylene sulfone, an alternative nitrification inhibitor to nitrapyrin for direct injection with anhydrous ammonia. Soil Res 56:752–763

Tilman D, Balzer C, Hill J, Befort BL (2011) Global food demand and the sustainable intensification of agriculture. Proc Natl Acad Sci 108(50):1–5

USDA-NRCS (1999) Soil taxonomy: a basic system of soil classification for making and interpreting soil surveys, 2nd edn. USDA Natural Resources Conservation Service, Washington, vol 436, p 886

Watts DB, Runion GB, Smith Nannenga KW, Torbert HA (2014) Enhanced-efficiency fertilizer effects on cotton yield and quality in the coastal plains. Agron J 106:745–752

Welsh J, Antille D L, Bradburn A, Macdonald BCT (2021) Assessment of the relationship between the most economic rate of nitrogen and nitrogen use efficiency—testing specific cotton, sugar, dairy and horticulture scenarios. Final Report More Profit from Nitrogen Program Project ID: CRDC-RRDP2109. Narrabri, NSW, Australia: Cotton Research and Development Corporation (Australian Government), p 5. https://www.crdc.com.au/sites/default/files/CRD21004-012%20Cross%20Sector%201%20Case%20Study_Mk6.pdf

Yan X, Ti C, Vitousek P, Chen D, Leip A, Cai Z, Zhu Z (2014) Fertilizer nitrogen recovery efficiencies in crop production systems of China with and without consideration of the residual effect of nitrogen. Environ Res Lett 9, Article number: 095002

Funding

Open Access funding enabled and organized by Projekt DEAL. This study was funded by the Australian Cotton Research and Development Corporation. We thank Julie Renwick and Sarah Carrick for their invaluable support during field work. The assistance of the different cotton growers, on whose properties this study was conducted, is gratefully acknowledged. CS and KF received funding by the German Federal Ministry of Education and Research (BMBF) under the "Make our Planet Great Again—German Research Initiative", Grant Number 306060, implemented by the German Academic Exchange Service (DAAD). Operational support provided by the Queensland University of Technology, the University of Southern Queensland, and CSIRO Agriculture and Food is appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Scheer, C., Rowlings, D.W., Antille, D.L. et al. Improving nitrogen use efficiency in irrigated cotton production. Nutr Cycl Agroecosyst 125, 95–106 (2023). https://doi.org/10.1007/s10705-022-10204-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10705-022-10204-6