Abstract

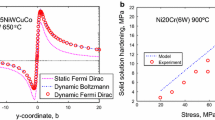

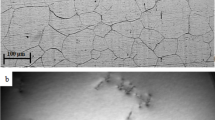

This article addresses experimental studies and analytical simulations of the tertiary creep stage of Grade 91 steel tested at various stresses and temperatures between 500°C (up to 160 × 103 h) and 600°C (up to 94 × 103 h). The strain rate increases after its minimum mainly because of the softening of the material which microstructure evolves strongly during creep deformation. An interrupted creep test shows that necking significantly affects the acceleration of the reduction in cross-section only during the last 10% of the creep lifetime. The Hoff model based on homogeneous reduction of cross-section correctly predicts lifetimes only for high applied stress. The Hart necking model using the Norton power-law allows fair predictions of lifetimes up to 60 × 103 h at 500°C. The necking model using a modified Norton power-law combined with a material softening term allows predictions of lifetimes for all creep tests, differing from the experimental results by less than 50%, which is consistent with the experimental scatter. The evolution of the cross-section predicted by this model is in agreement with measurements carried out during the interrupted creep test. Two prediction rules for the lifetime prediction are deduced from the necking model that takes into account the material softening. For a large number of tempered martensitic steels, these two criteria bound the experimental lifetimes up to 200 × 103 h at 500–700°C.

Similar content being viewed by others

Abbreviations

- A :

-

Constant of the power function given by Eq. 2, (h−α)

- C :

-

Coefficient of the Norton power-law (MPa−N h−1)

- D :

-

Diameter of the creep specimen (mm)

- k :

-

Slope of creep softening

- N :

-

Exponent of the Norton power-law

- r c :

-

Necking section at fracture divided by the initial cross-section = s(rupture)/S init

- r inf :

-

Inferior limit of the fraction of the necking section

- r sup :

-

Superior limit of the fraction of the necking section

- S :

-

Cross-section of the homogeneous part of the creep specimen (mm2)

- S min :

-

Cross-section of the homogeneous part of the creep specimen when the strain rate reaches the minimum (mm2)

- S init :

-

Cross-section of the creep specimen at the initial state (mm2)

- s :

-

Necking cross-section of the creep specimen (mm2)

- s min :

-

Necking cross-section of the creep specimen when the strain rate reaches the minimum (mm2)

- t :

-

Time (h)

- t min :

-

Time when the strain rate reaches the minimum (h)

- t R :

-

Time to rupture (h)

- t Rinf :

-

Lifetime predicted by the lower bound law (h)

- t Rsup :

-

Lifetime predicted by the upper bound law (h)

- T :

-

Temperature (°C)

- α :

-

Exponent of the power function given by Eq. 2

- δ D :

-

Variation in diameter caused by the roughness of specimen surface (μm)

- δ D necking :

-

Difference in diameter between the homogeneous cross-section and the necking cross-section at the onset of necking (μm)

- δ D r :

-

Variation in diameter relative to the average diameter of the specimen = δ D/D

- δ S :

-

Difference in area between the homogeneous cross-section and the necking cross-section (mm2)

- ε :

-

True or logarithm strain

- ε eng :

-

Engineering strain or relative elongation

- ε min :

-

True strain at which the true strain rate reaches the minimum

- \({\varepsilon_{min}^{eng}}\) :

-

Engineering strain corresponding to ε min (h−1)

- \({\dot{\varepsilon}_{min}}\) :

-

Minimum true strain rate (h−1)

- \({\dot{\varepsilon}_{min}^{eng}}\) :

-

Minimum engineering strain rate (h−1)

- \({\dot{\varepsilon}_{min}^{Norton}}\) :

-

Minimum true strain rate predicted by the Norton power-law (h−1)

- σ :

-

True stress (MPa)

- σ eng :

-

Engineering stress (MPa)

- σ hom :

-

True stress in the cross-sections of the homogeneous parts (MPa)

- σ necking :

-

True stress in the necking cross-section (MPa)

References

Abe F (2008) Stress to produce a minimum creep rate of 10−5%/h and stress to cause rupture at 105 h for ferritic and austenitic steels and superalloys. Int J Press Vessel Pip 85: 99–107

Abe F, Horiuchi T, Taneike M, Kimura K, Muneki S, Igarahi M (2001) Creep strain behavior during microstructure evolution in tempered martensitic advanced 9Cr steels. In: Proceedings of the 10th joint international conference on creep and fracture of engineering materials and structures—part: creep resistant metallic materials, published by VĺTKOVICE-Research and Development, Czech Republic, pp 16–25

Auzoux Q (2004) Ph.D. thesis: Reheat cracking of austenitic stainless steels—influence of work hardening on intergranular damage, MINES ParisTech and CEA Saclay, DEN/DMN/SRMA (in French), http://pastel.paristech.org/659/

Bonade R, Spätig P, Schäublin R, Victoria M (2004) Plastic flow of martensitic model alloys. Mater Sci Eng A 387–389: 16–21

Bridgman PW (1944) The stress distribution at the neck of a tension specimen. Trans ASME 32: 553–574

Čadek J, Šustek V, Pahutová M (1997) An analysis of a set of creep data for a 9Cr-1Mo-0.2V (P91 type) steel. Mater Sci Eng A 225: 22–28

Cerri E, Evangelista E, Spigarelli S, Bianchi P (1998) Evolution of microstructure in a modified 9Cr–1Mo steel during short term creep. Mater Sci Eng A 245: 285–292

Considère M (1885) Mémoire sur l’emploi du fer et de l’acier dans les constructions. Annales des Ponts et Chaussées 9: 574 (in French)

Dumoulin S, Tabourot L, Chappuis C, Vacher P, Arrieux R (2003) Determination of the equivalent stress-equivalent strain relationship of a copper sample under tensile loading. J Mater Process Technol 133: 79–83

Eggeler G, Earthman JC, Nilsvang N (1989) Microstructural study of creep rupture in a 12% chromium ferritic steel. Acta Metall 37: 49–60

Fournier B, Sauzay M, Mottot M, Brillet H, Monnet I, Pineau A (2005) Experimentally based modelling of cyclically induced softening in a martensitic steel at high temperature. In: International conference on creep and fracture in high temperature components—design and life assessment issues, organized by ECCC, London

Gaffard V (2005) Ph.D thesis: Experimental study and modeling of high temperature creep flow and damage behaviour of 9Cr1Mo-NbV steels and weldments, Ecole des Mines de Paris (in English), http://pastel.paristech.org/1287/

Gieseke B, Brinkman C, and Maziasz P (1993) The influence of thermal aging on the microstructure and fatigue properties of modified 9Cr-1Mo steel. In: 1st International conference on microstructures and mechanical properties of aging materials, pp 107–115

Giroux PF, Dalle F, Sauzay M, Malaplate J, Fournier B, Gourgues-Lorenzon AF (2010) Mechanical and microstructural stability of P92 steel under uniaxial tension at high temperature. Mater Sci Eng A (in press)

Hald J (2004) Creep strength and ductility of 9 to 12% chromium steels. Mater High Temp 21: 41–46

Haney EM, Dalle F, Sauzay M, Vincent L, Tournié I, Allais L, Fournier B (2009) Macroscopic results of long-term creep on a modified 9Cr-1Mo steel. Mater Sci Eng A 510–511: 99–103

Hart EW (1967) Theory of the tensile test. Acta Metall 15: 351–355

Hoff NJ (1953) The necking and the rupture of rods subjected to constant tensile loads. J Appl Mech 20(1): 105–108

Igarashi M, Muneki S, Kutsumi H, Itagaki T, Fujitsuna N, Abe F (2000) A new concept for strengthening of advanced ferritic steels for USC power plant. In: Parsons 2000 advanced materials for 21st century turbines and power plant. Proceedings of the 5th international Charles Parsons turbine conference, pp 334–347

Kimura K, Kushima H, Abe F, Yagi K (1997) Inherent creep strength and long-term creep strength properties of ferritic steels. Mater Sci Eng A 234–236: 1079–1082

Kimura K, Kushima H, Sawada K (2009) Long-term creep deformation property of modified 9Cr-1Mo steel. Mater Sci Eng A 510–511: 58–63

Kitahara H, Ueji R, Tsuji N, Minamino Y (2006) Crystallographic features of lath martensite in low-carbon steel. Acta Mater 54: 1279–1288

Lemaitre J, Chaboche JL (1994) Mechanics of solid materials. Cambridge University Press, Cambridge, p 257

Lloyd GJ (1980) The relation between creep crack growth rates and creep-fatigue crack growth rates in austenitic type 316 steel. In: International conference on engineering aspects of creep 1. Mechanical Engineering Publications Limited, London, pp 239–248

Masuyama F (2008) Hardness models for creep life assessment of high strength martensitic steels. Mater Sci Eng A 510–511: 154–157

Matsuda F, Fujkawa T (1980) Reference stress approach for estimation creep strain of tapered cylindrical vessels. In: International conference on engineering aSPECTS of creep 2. Mechanical Engineering Publications Limited, London, pp 51–56

Milicka K, Dobes K (2006) Small punch testing of Grade 91 steel. Int J Press Vessel Pip 83: 625–634

Monkman FC, Grant NJ (1956) An empirical relationship between rupture life and minimum creep rate in creep rate in creep-rupture tests. Proc ASTM 56: 593

Orlová A, Buršík J, Kuchařová K, Sklenička V (1998) Microstructural development during high temperature creep of 9%Cr steel. Mater Sci Eng A 245: 39–48

Pešička J, Dronhofer A, Eggeler G (2004) Free dislocations and boundary dislocations in tempered martensitic ferritic steels. Mater Sci Eng A 387–389: 176–180

Sawada K, Takeda M, Maruyama K, Ishii R, Yamada M, Nagae Y, Komine R (1999) Effect of W on recovery of lath structure during creep of high chromium martensitic steels. Mater Sci Eng A 267: 19–25

Sawada K, Kubo K, Abe F (2001) Creep behaviour and stability of MX precipitates at high temperature in 9Cr-0.5Mo-1.8W-VNb steel. Mater Sci Eng A 319–321: 784–787

Senior BA, Noble FW, Eyre BL (1986) The nucleation and growth of voids at carbides in 9Cr-1Mo steel. Acta. Metall 34(7): 1321–1327

Shankar V, Valsan M, Bhanu Sankara Rao K, Kannan R, Mannan S, Pathak S (2006) Low cycle fatigue behaviour and microstructural evolution of modified 9Cr-1Mo ferritic steel. Mater Sci Eng A 437: 413–422

Sklenička V, Kuchařová K, Svoboda M, Kloc L, Buršík J, Kroupa A (2003) Long-term creep behaviour of 9–12%Cr power plant steels. Mater Charact 51: 35–48

Spigarelli S, Cerri E, Bianchi P, Evangelista E (1999) Interpretation of creep behaviour of a 9Cr-Mo-Nb-V-N (T91) steel using threshold stress concept. Mater Sci Technol 15: 1433–1440

Straub S, Meier M, Ostermann J, Blum W (1993) Development of Microstructure and Strengthening in Ferritic Steel X20CrMoV 12 1 at 823K During Long-Term Creep Tests and During Annealing. VGB Kraftwerkstechnik 73(8): 646–653 (in German)

Vaillant JC, Vandenberghe B, Hahn B, Heuser H, Jochum C (2008) T/P23, 24, 911 and 92: new grades for advanced coal-fired power plants—properties and experience. Int J Press Vessel Pip 85: 38–46

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article can be found at http://dx.doi.org/10.1007/s10704-011-9594-x

Rights and permissions

About this article

Cite this article

Lim, R., Sauzay, M., Dalle, F. et al. Modelling and experimental study of the tertiary creep stage of Grade 91 steel. Int J Fract 169, 213–228 (2011). https://doi.org/10.1007/s10704-011-9585-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-011-9585-y