Abstract

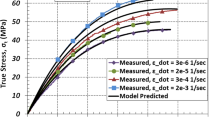

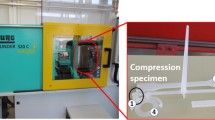

Observations are reported on isotactic polypropylene in uniaxial tensile tests with various strain rates, relaxation tests with various strains, and creep tests with various stresses at ambient temperature. Constitutive equations are derived for the viscoelastic–viscoplastic responses and damage of a semicrystalline polymer at three-dimensional deformations. Adjustable parameters in the stress–strain relations are found by fitting the experimental data. The model is applied to predict creep-failure diagrams in the entire interval of stresses. A phenomenological approach is proposed to determine a knee stress, at which transition occurs from ductile to brittle rupture. Accuracy of this method is evaluated by numerical simulation.

Similar content being viewed by others

References

Alwis KGNC, Burgoyne CJ (2006) Time-temperature superposition to determine the stress-rupture of aramid fibres. Appl Compos Mater 13: 249–264

Alwis KGNC, Burgoyne CJ (2008) Accelerated creep testing for aramid fibres using the stepped isothermal method. J Mater Sci 43: 4789–4800

Bergstrom JS, Kurtz SM, Rimnac CM, Edidin AA (2002) Constitutive modeling of ultra-high molecular weight polyethylene under large-deformation and cyclic loading conditions. Biomaterials 23: 2329–2343

Bauwens-Crowet C, Ots J-M, Bauwens J-C (1974) The strain-rate and temperature dependence of yield of polycarbonate in tension, tensile creep and impact tests. J Mater Sci 9: 1197–1201

Barton SJ, Cherry BW (1979) Predicting the creep rupture life of polyethylene pipe. Polym Eng Sci 19: 590–595

Ben Hadj Hamouda H, Simoes-Betbeder M, Grillon F, Blouet P, Billon N, Piques R (2001) Creep damage mechanisms in polyethylene gas pipes. Polymer 42: 5425–5437

Ben Hadj Hamouda H, Laiarinandrasana L, Piques R (2007) Fracture mechanics global approach concepts applied to creep slow crack growth in a medium density polyethylene (MDPE). Eng Fracture Mech 74: 2187–2204

Bodner SR (1992) Unified plasticity for engineering applications. Kluwer, New York

Brueller OS (1981) Energy-related failure criteria of thermoplastics. Polym Eng Sci 21: 145–150

Bueno BS, Costanzi MA, Zornberg JG (2005) Conventional and accelerated creep tests on nonwoven needle-punched geotextiles. Geosynth Int 12: 276–287

Cai H, Miyano Y, Nakada M, Ha SK (2008) Long-term fatigue strength prediction of CFRP structure based on micromechanics of failure. J Compos Mater 42: 825–844

Derrida B (1980) Random-energy model: limit of a family of disordered models. Phys Rev Lett 45: 79–92

Golub VP, Pogrebnyak AD, Chernetskaya EV (2000) The kinetics of creep embrittlement under long-term static loading. Int Appl Mech 36: 795–802

Greenwood GW (1976) Fracture under creep conditions. Mater Sci Engng 25: 241–245

Greenwood GW (1990) Mechanistic interpretations of some empirical correlations in creep and creep fracture. ISIJ Int 30: 795–801

Guedes RM (2006) Lifetime predictions of polymer matrix composites under constant or monotonic load. Composites A 37: 703–715

Holmstrom S, Auerkari P (2008) Effect of short-term data on predicted creep rupture life–Pivoting effect and optimized censoring. Mater High Temp 25: 103–109

Janssen RPM, Govaert LE, Meijer HEH (2008) An analytical method to predict fatigue life of thermoplastics in uniaxial loading: sensitivity to wave type, frequency, and stress amplitude. Macromolecules 41: 2531–2540

Kachanov LM (1999) Rupture time under creep conditions. Int J Fracture 97: 11–18

Kaliske M, Nasdala L, Rothert H (2001) On damage modelling for elastic and viscoelastic materials at large strain. Comp Struct 79: 2133–2141

Klompen ETJ, Engels TAP, van Breemen LCA, Schreurs PJG, Govaert LE, Meijer HEH (2005) Quantitative prediction of long-term failure of polycarbonate. Macromolecules 38: 7009–7017

Kolarik J, Pegoretti A (2006) Non-linear tensile creep of polypropylene: Time-strain superposition and creep prediction. Polymer 47: 346–356

Kongkitkul W, Tatsuoka F (2007) A theoretical framework to analyse the behaviour of polymer geosynthetic reinforcement in temperature-accelerated creep tests. Geosynth Int 14: 23–38

Krishnaswamy RK (2005) Analysis of ductile and brittle failures from creep rupture testing of high-density polyethylene (HDPE) pipes. Polymer 46: 11664–11672

Krishnaswamy RK (2007) Influence of wall thickness on the creep rupture performance of polyethylene pipe. Polym Eng Sci 47: 516–521

Leckie FA, Hayherst DR (1974) Creep rupture of structures. Proc Roy Soc London A 340: 323–347

Levesque M, Derrien K, Baptiste D, Gilchrist MD (2008) On the development and parameter identification of Schapery-type constitutive theories. Mech Time-Dependent Mater 12: 95–127

Little RE, Mitchell WJ, Mallick PK (1995) Tensile creep and creep rupture of continuous strand mat polypropylene composites. J Compos Mater 29: 2215–2217

Lin RC, Schomburg U (2003) A finite elastic-viscoelastic-elastoplastic material law with damage: theoretical and numerical aspects. Comp Meth Appl Mech Engng 192: 1591–1627

Lu X, Brown N (1990) The transition from ductile to slow crack growth failure in a copolymer of polyethylene. J Mater Sci 25: 411–416

Lu X, Brown N (1991) Unification of ductile failure and slow crack growth in an ethylene-octene copolymer. J Mater Sci 26: 612–620

Marklund E, Eitzenberger J, Varna J (2008) Nonlinear viscoelastic viscoplastic material model including stiffness degradation for hemp/lignin composites. Compos Sci Technol 68: 2156–2162

Mishnaevsky L, Brondsted P (2008) Micromechanical modeling of damage and fracture of unidirectional fiber reinforced composites: A review. Comput Mater Sci 44: 1351–1359

Orifici AC, Herszberg I, Thomson RS (2008) Review of methodologies for composite material modelling incorporation failure. Comp Struct 86: 194–210

Schapery RA (1999) Nonlinear viscoelastic and viscoplastic constitutive equations with growing damage. Int J Fracture 97: 33–66

Simo JC (1987) On a fully three-dimensional finite-strain viscoelastic damage model: Formulation and computational aspects. Comp Meth Appl Mech Engng 60: 153–173

Tanaka F, Edwards SF (1992) Viscoelastic properties of physically cross-linked networks. Transient network theory. Macromolecules 25: 1516–1523

Teoh SH, Cherry BW, Kaush HH (1992) Creep rupture modelling of polymers. Int J Damage Mech 1: 245–256

Wang XC, Habraken AM (1996) An elastic-visco-plastic damage model: from theory to applications. J Phys IV C 6: 549–558

Zhurkov SN (1964) Kinetic concept of the strength of solids. Int J Fracture Mech 1: 311–323

Zornberg JG, Byler BR, Knudsen JW (2004) Creep of geotextiles using time-temperature superposition methods. J Geotech Geoenviron Eng 130: 1158–1168

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Drozdov, A.D., Christiansen, J.d. Creep failure of polypropylene: experiments and constitutive modeling. Int J Fract 159, 63–79 (2009). https://doi.org/10.1007/s10704-009-9384-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-009-9384-x