Abstract

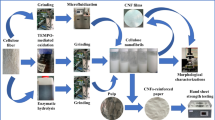

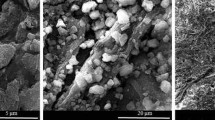

The mechanical strength degradation of recycled paper (RP) caused by the keratinization of recycled fibers is a basic problem to be solved urgently in the waste paper recycling industry. Compensating RP strength in a sustainable pathway is imperative and challenging. Cellulose nanofibrils with a three-dimensional interpenetrating network structure (3DIPN-CNFs) developed as a new family of strength additives for RP were demonstrated herein. The 3DIPN-CNFs were obtained from bagasse in a single bath treatment with H3PO4 and H2O2 under mild aqueous conditions. The tensile index and tear index of the RP with 3DIPN-CNFs were increased by 78% and 39%, respectively. 3DIPN-CNFs are less expensive and easier to obtain than Isolated-CNFs because homogenizing mechanical treatment is not required and are expected to become a sustainable strength additive for RP.

Similar content being viewed by others

References

Adsul M, Soni SK, Bhargava SK, Bansal V (2012) Facile approach for the dispersion of regenerated cellulose in aqueous system in the form of nanoparticles. Biomacromol 13:2890–2895. https://doi.org/10.1021/bm3009022

Afra E, Yousefi H, Hadilam MM, Nishino T (2013) Comparative effect of mechanical beating and nanofibrillation of cellulose on paper properties made from bagasse and softwood pulps. Carbohydr Polym 97:725–730

Alexander LE (1979) X-ray diffraction methods in polymer science. Robert E Kreiger Publishing Co, Humington, New York, pp 423–424

Alves L, Medronho B, Antunes FE, Topgaard D, Lindman B (2016) Dissolution state of cellulose in aqueous systems. 2. Acidic Solvents Carbohydr Polym 151:707–715

Arminen H, Hujala M, Puumalainen K, Tuppura A, Toppinen A (2013) An update on inter-country differences in recovery and utilization of recycled paper. Resour Conserv Recycl 78:124–135

Boufi S, González I, Delgado-Aguilar M, Tarrès Q, Pèlach MÀ, Mutjé P (2016) Nanofibrillated cellulose as an additive in papermaking process: a review. Carbohydr Polym 154:151–166

Brodin FW, Eriksen Ø (2015) Preparation of individualised lignocellulose microfibrils based on thermomechanical pulp and their effect on paper properties. Nord Pulp Paper Res J 30:443–451

Cai C, Luo B, Liu Y, Fu Q, Liu T, Wang S, Nie S (2021) Advanced triboelectric materials for liquid energy harvesting and emerging application. Mater Today, In press.

Campano C, Merayo N, Negro C, Blanco Á (2018) Low-fibrillated bacterial cellulose nanofibers as a sustainable additive to enhance recycled paper quality. Int J Biol Macromol 114:1077–1083

Charani PR, Dehghani-Firouzabadi M, Afra E, Blademo Å, Naderi A, Lindström T (2013) Production of microfibrillated cellulose from unbleached kraft pulp of Kenaf and Scotch Pine and its effect on the properties of hardwood kraft: microfibrillated cellulose paper. Cellulose 20:2559–2567

China Technical Association of Paper Industry (2010) Almanac of China paper industry. China Light Industry Press, Beijing

Delgado-Aguilar M, González I, Pèlach M, De La Fuente E, Negro C, Mutjé P (2015) Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22:789–802

Eriksen Ø, Syverud K, Gregersen Ø (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nord Pulp Paper Res J 23:299–304

Filson PB, Dawson-Andoh BE, Schwegler-Berry D (2009) Enzymatic-mediated production of cellulose nanocrystals from recycled pulp. Green Chem 11:1808–1814

Fu H, Gao W, Wang B, Zeng J, Cheng Z, Xu J, Chen K (2020) Effect of lignin content on the microstructural characteristics of lignocellulose nanofibrils. Cellulose 27:1327–1340. https://doi.org/10.1007/s10570-019-02859-2

Fu Q, Liu Y, Mo J, Lu Y, Cai C et al. (2021) Improved capture and removal efficiency of gaseous acetaldehyde by a self-powered photocatalytic system with an external electric field. ACS nano

Hai LV, Zhai L, Kim HC, Panicker PS, Pham DH, Kim J (2020) Chitosan nanofiber and cellulose nanofiber blended composite applicable for active food packaging. Nanomaterials 10:1752

Hassan EA, Hassan ML, Oksman K (2011) Improving bagasse pulp paper sheet properties with microfibrillated cellulose isolated from xylanase-treated bagasse. Wood Fiber Sci 43:76–82

Hassan ML, Bras J, Mauret E, Fadel SM, Hassan EA, El-Wakil NA (2015) Palm rachis microfibrillated cellulose and oxidized-microfibrillated cellulose for improving paper sheets properties of unbeaten softwood and bagasse pulps. Ind Crop Prod 64:9–15

Hassan EA, Hassan ML, Abou-Zeid RE, El-Wakil NA (2016) Novel nanofibrillated cellulose/chitosan nanoparticles nanocomposites films and their use for paper coating. Ind Crop Prod 93:219–226

Hollertz R, Durán VL, Larsson PA, Wågberg L (2017) Chemically modified cellulose micro-and nanofibrils as paper-strength additives. Cellulose 24:3883–3899

Hubbe MA (2014) Prospects for maintaining strength of paper and paperboard products while using less forest resources: a review. BioResources 9:1634–1763

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85

Jiang Y, Wang Z, Liu X, Yang Q, Huang Q et al (2020) Highly transparent, UV-shielding, and water-resistant lignocellulose nanopaper from agro-industrial waste for green optoelectronics. ACS Sustain Chem Eng 8:17508–17519

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Edit 50:5438–5466

Li X, Wang J, Yan D, Yin Y, Wang S (2020) Influence of sodium carbonate addition on weight loss of bagasse alkaline black liquor during pyrolysis. BioResources 15:2428–2441

Liimatainen H, Visanko M, Sirvio JA, Hormi OEO, Niinimaki J (2012) Enhancement of the nanofibrillation of wood cellulose through sequential periodate-chlorite oxidation. Biomacromol 13:1592–1597. https://doi.org/10.1021/bm300319m

Lin X, Wu Z, Zhang C, Liu S, Nie S (2018) Enzymatic pulping of lignocellulosic biomass. Ind Crop Prod 120:16–24

Lindman B, Medronho B, Alves L, Norgren M, Nordenskiöld L (2021) Hydrophobic interactions control the self-assembly of DNA and cellulose. Q Rev Biophys 54.

Liu X, Jiang Y, Song X, Qin C, Wang S, Li K (2019) A bio-mechanical process for cellulose nanofiber production–towards a greener and energy conservation solution. Carbohydr Polym 208:191–199

Liu Y, Mo J, Fu Q, Lu Y, Zhang N, Wang S, Nie S (2020) Enhancement of triboelectric charge density by chemical functionalization. Adv Func Mater 30:2004714

Liu Y, Fu Q, Mo J, Lu Y, Cai C, Luo B, Nie S (2021) Chemically tailored molecular surface modification of cellulose nanofibrils for manipulating the charge density of triboelectric nanogenerators. Nano Energy 89:106369

Mo J, Zhang C, Lu Y, Liu Y, Zhang N, Wang S, Nie S (2020) Radial piston triboelectric nanogenerator-enhanced cellulose fiber air filter for self-powered particulate matter removal. Nano Energy 78:105357

Mourdikoudis S, Pallares RM, Thanh NT (2018) Characterization techniques for nanoparticles: comparison and complementarity upon studying nanoparticle properties. Nanoscale 10:12871–12934

Nazhad MM, Paszner L (1994) Fundamentals of strength loss in recycled paper. Tappi J 77.

Nie S, Wang S, Qin C, Yao S, Ebonka JF, Song X, Li K (2015) Removal of hexenuronic acid by xylanase to reduce adsorbable organic halides formation in chlorine dioxide bleaching of bagasse pulp. Bioresour Technol 196:413–417

Nie S, Zhang C, Zhang Q, Zhang K, Zhang Y, Tao P, Wang S (2018a) Enzymatic and cold alkaline pretreatments of sugarcane bagasse pulp to produce cellulose nanofibrils using a mechanical method. Ind Crop Prod 124:435–441

Nie S, Zhang K, Lin X, Zhang C, Yan D, Liang H, Wang S (2018b) Enzymatic pretreatment for the improvement of dispersion and film properties of cellulose nanofibrils. Carbohydr Polym 181:1136–1142

Rosa SM, Rehman N, de Miranda MIG, Nachtigall SM, Bica CI (2012) Chlorine-free extraction of cellulose from rice husk and whisker isolation. Carbohyd Polym 87:1131–1138

Sain M, Panthapulakkal S (2006) Bioprocess preparation of wheat straw fibers and their characterization. Ind Crop Prod 23:1–8

Saito T, Nishiyama Y, Putaux JL, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromol 7:1687–1691. https://doi.org/10.1021/bm060154s

Salam A, Lucia LA, Jameel H (2013) A novel cellulose nanocrystals-based approach to improve the mechanical properties of recycled paper. ACS Sustain Chem Eng 1:1584–1592

Sehaqui H, Allais M, Zhou Q, Berglund LA (2011) Wood cellulose biocomposites with fibrous structures at micro-and nanoscale. Compos Sci Technol 71:382–387

Su J, Mosse WK, Sharman S, Batchelor WJ, Garnier G (2013) Effect of tethered and free microfibrillated cellulose (MFC) on the properties of paper composites. Cellulose 20:1925–1935

Sun R, Sun XF, Liu GQ, Fowler P, Tomkinson J (2002) Structural and physicochemical characterization of hemicelluloses isolated by alkaline peroxide from barley straw. Polym Int 51:117–124. https://doi.org/10.1002/pi.815

Sun XF, Xu F, Sun RC, Fowler P, Baird MS (2005) Characteristics of degraded cellulose obtained from steam-exploded wheat straw. Carbohyd Res 340:97–106. https://doi.org/10.1016/j.carres.2004.10.022

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020

Tajik M, Torshizi HJ, Resalati H, Hamzeh Y (2018) Effects of cationic starch in the presence of cellulose nanofibrils on structural, optical and strength properties of paper from soda bagasse pulp. Carbohydr Polym 194:1–8

Tang Y, Shen X, Zhang J, Guo D, Kong F, Zhang N (2015) Extraction of cellulose nano-crystals from old corrugated container fiber using phosphoric acid and enzymatic hydrolysis followed by sonication. Carbohydr Polym 125:360–366

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci Appl Polym Symp 9:815–827

Wang Y, Yuan B, Ji Y, Li H (2013) Hydrolysis of hemicellulose to produce fermentable monosaccharides by plasma acid. Carbohydr Polym 97:518–522

Wang J, Li X, Song J, Wu K, Xue Y, Wu Y, Wang S (2020a) Direct preparation of cellulose nanofibers from bamboo by nitric acid and hydrogen peroxide enables fibrillation via a cooperative mechanism. Nanomaterials 10:943

Wang J, Wang Q, Wu Y, Bai F, Wang H et al (2020b) Preparation of cellulose nanofibers from bagasse by phosphoric acid and hydrogen peroxide enables fibrillation via a swelling, hydrolysis, and oxidation cooperative mechanism. Nanomaterials 10:2227

Wang J, Chen W, Dong T, Wang H, Si S, Li X (2021b) Enabled cellulose nanopaper with outstanding water stability and wet strength via activated residual lignin as a reinforcement. Green Chem 23:10062–10070

Wang H, Wang J, Si S, Wang Q, Li X, Wang S (2021a) Residual-lignin-endowed molded pulp lunchbox with a sustained wet support strength. Ind Crop Prod 170:113756

Xu Y, Yang S, Zhao P, Wu M, Song X, Ragauskas AJ (2021) Effect of endoglucanase and high-pressure homogenization post-treatments on mechanically grinded cellulose nanofibrils and their film performance. Carbohydr Polym 253:117253

Yang X, Berglund LA (2019) Recycling without fiber degradation—strong paper structures for 3d forming based on nanostructurally tailored wood holocellulose fibers. ACS Sustain Chem Eng 8:1146–1154

Yue Y, Han J, Han G, Aita GM, Wu Q (2015) Cellulose fibers isolated from energycane bagasse using alkaline and sodium chlorite treatments: structural, chemical and thermal properties. Ind Crop Prod 76:355–363

Zhang Y-HP, Cui J, Lynd LR, Kuang LR (2006) A transition from cellulose swelling to cellulose dissolution by o-phosphoric acid: evidence from enzymatic hydrolysis and supramolecular structure. Biomacromol 7:644–648

Zhang C, Mo J, Fu Q, Liu Y, Wang S, Nie S (2021) Wood-cellulose-fiber-based functional materials for triboelectric nanogenerators. Nano Energy 81:105637

Acknowledgments

This project was sponsored by research funds from Guangxi Natural Science Foundation (2017GXNSFAA198220 and 2018GXNSFAA294074). The authors are grateful for the financial support from the Guangxi Key Laboratory of Clean Pulp & Papermaking and Pollution Control.

Funding

The study was performed within the Guangxi Natural Science Foundation (project #2017GXNSFAA198220 and #2018GXNSFAA294074), and funded by the Guangxi Science and Technology Department.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, J., Wu, Y., Chen, W. et al. Cellulose nanofibrils with a three-dimensional interpenetrating network structure for recycled paper enhancement. Cellulose 29, 3773–3785 (2022). https://doi.org/10.1007/s10570-022-04496-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04496-8